Thank you, although I can claim no credit for it, just saw it online.

Getting closer to the finish line. Well maybe not the finish, but the next step which is inspection by the engineer. I've already talked to him about the build and he doesnt need things to be painted, just built right, so I'm pushing ahead with the dry build then will tear it apart for paint/carpet after his signoff as I can't insure it so can't drive it until he signs it off.

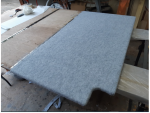

The only thing he flagged in our conversation was the seat mounts. I had put spreader plates underneath but never found any spec for them. They need to be a minimum of 100x100x4mm with the hole centred. where it's not possible to centre the hole because of a chassis member you must bend the plate and still have it as big. I was wondering how the hell I'd bend such steel, I've a well equipped shop but no brake when suddenly it dawned on me to use box. I was expecting a day long battle, my daughter was booked to help, I was expecting tempers to be frayed.

Nope. about 2 hours with the lidl plasma playing a blinder and we were done, and all over spec too. flat plates are 100x150x5 and the box pieces all work out at 100x120x5

While we were underneath we also ran the power cables. I'm going with a very simple 12v install, it will nearly all be in the one small area where the fridge, lights and water pump are concentrated. I believe in overkill though so have run 10mm2 wires directly to the battery box inside some black MDPE pipe. (again showing my rural roots this is recycled from the farm, you can tell too! ) tried a trick I've read but never used for fishing the wire through the pipe. a piece of tissue paper tied on the end of a string and blow it through with the air line, worked a treat. The floor crossmembers had some holes that were made for the job and we were able to fish a tig rod through them over the fuel tank so have a completely enclosed cable run from inside the rear to the battery box under the floor.

The kitchen cabinet has moved onto the F word, it's essentially done now bar the door which I have failed to find latches for locally yet and none of the irish camper shops online seem to have them in stock.

The sink got drilled for a waste outlet and we dimpled it with an M24 bolt, some washers and pipe. the waste pipe is supported by some cable ties and goop. it will be secured when installed, after the painting.

Got the water tank/pump installed on saturday too. sitting on a shelf between the floor of the wardrobe and the wheelarch it leaves just enough room underneath/in front of the arch for the pump install. The water tank is a 35l plastic jerry that had a tap on it. I removed the tap and found this plastic tank connector which with a bit of sanding was a perfect fit in its place. a bent piece of tube runs to the bottom of the tank and the whole assembly has been epoxied for water tightness. I'm still waiting on some fittings to put a tank filler/vent in place.

I've also started cutting the wadrobe. it's going to be a simple box with three sides, the main side will have two holes in it and a shelf. no doors as it's going to be for soft bags/bedding so will be stuffed and shouldnt need retaining. Sadly this is where our happy weekend of productivity takes a sad twist. two weeks ago I got a Triton track saw which had massively improved my plywood work, accuracy fit and finish were leagues better than I could have managed with the circular saw. I have an 80 tooth blade and it leaves birch ply looking so sharp. The kitchen cabinet would be a mess of gaps and tearout and a whole tub of bondo without it. While cutting the wardrobe panels yesterday morning it took a dive face first onto concrete and the safety latch pin bust out through the casting. Not impressed with the quality of metal in it to be honest, but at the same time not sure a better brand would have fared much better. I'm now faced with the dilemma of do I buy a higher grade tool or go triton again and have a pretty full set of spares from this one!

I'm calling the engineer today to book an appointment, hoping he can come next week.

Have the following left to do to finish the dry build, I have all the bits needed either already arrived or on order except for the kitchen door latches which I need to sort today.

Getting closer to the finish line. Well maybe not the finish, but the next step which is inspection by the engineer. I've already talked to him about the build and he doesnt need things to be painted, just built right, so I'm pushing ahead with the dry build then will tear it apart for paint/carpet after his signoff as I can't insure it so can't drive it until he signs it off.

The only thing he flagged in our conversation was the seat mounts. I had put spreader plates underneath but never found any spec for them. They need to be a minimum of 100x100x4mm with the hole centred. where it's not possible to centre the hole because of a chassis member you must bend the plate and still have it as big. I was wondering how the hell I'd bend such steel, I've a well equipped shop but no brake when suddenly it dawned on me to use box. I was expecting a day long battle, my daughter was booked to help, I was expecting tempers to be frayed.

Nope. about 2 hours with the lidl plasma playing a blinder and we were done, and all over spec too. flat plates are 100x150x5 and the box pieces all work out at 100x120x5

While we were underneath we also ran the power cables. I'm going with a very simple 12v install, it will nearly all be in the one small area where the fridge, lights and water pump are concentrated. I believe in overkill though so have run 10mm2 wires directly to the battery box inside some black MDPE pipe. (again showing my rural roots this is recycled from the farm, you can tell too! ) tried a trick I've read but never used for fishing the wire through the pipe. a piece of tissue paper tied on the end of a string and blow it through with the air line, worked a treat. The floor crossmembers had some holes that were made for the job and we were able to fish a tig rod through them over the fuel tank so have a completely enclosed cable run from inside the rear to the battery box under the floor.

The kitchen cabinet has moved onto the F word, it's essentially done now bar the door which I have failed to find latches for locally yet and none of the irish camper shops online seem to have them in stock.

The sink got drilled for a waste outlet and we dimpled it with an M24 bolt, some washers and pipe. the waste pipe is supported by some cable ties and goop. it will be secured when installed, after the painting.

Got the water tank/pump installed on saturday too. sitting on a shelf between the floor of the wardrobe and the wheelarch it leaves just enough room underneath/in front of the arch for the pump install. The water tank is a 35l plastic jerry that had a tap on it. I removed the tap and found this plastic tank connector which with a bit of sanding was a perfect fit in its place. a bent piece of tube runs to the bottom of the tank and the whole assembly has been epoxied for water tightness. I'm still waiting on some fittings to put a tank filler/vent in place.

I've also started cutting the wadrobe. it's going to be a simple box with three sides, the main side will have two holes in it and a shelf. no doors as it's going to be for soft bags/bedding so will be stuffed and shouldnt need retaining. Sadly this is where our happy weekend of productivity takes a sad twist. two weeks ago I got a Triton track saw which had massively improved my plywood work, accuracy fit and finish were leagues better than I could have managed with the circular saw. I have an 80 tooth blade and it leaves birch ply looking so sharp. The kitchen cabinet would be a mess of gaps and tearout and a whole tub of bondo without it. While cutting the wardrobe panels yesterday morning it took a dive face first onto concrete and the safety latch pin bust out through the casting. Not impressed with the quality of metal in it to be honest, but at the same time not sure a better brand would have fared much better. I'm now faced with the dilemma of do I buy a higher grade tool or go triton again and have a pretty full set of spares from this one!

I'm calling the engineer today to book an appointment, hoping he can come next week.

Have the following left to do to finish the dry build, I have all the bits needed either already arrived or on order except for the kitchen door latches which I need to sort today.