During the winter we got together with a couple of other rigs for a winter camping trip, it normally doesnt get that cold around but that weekend it dropped to -17 Celsius! Which would be our coldest camp out that we have had the truck on. We struggled to keep the camper warm all over , just not enough air circulation behind all the cabinets low down, as a result our water pipes froze up overnight and I had to warm them up to get water, but what was worse was that the bottom of our water tank froze and when it did some pockets or voids in my epoxy work filled with water and expanded when frozen and unknown to us for many months later that it created a tiny water leak just behind the shoe storage that sits next to the tank. I guess it leaked from then on for months and never enough to actually show up but it did find some spots that were not well epoxied and got into the plywood layers and started to rot the wood away, major disappointment for me but whatever, get it fixed!

The good was that I got to really do some mods and clean up the electrical.

Our winter camping trip.

And one of the guys actually tented it! We are too wimpy for that now.

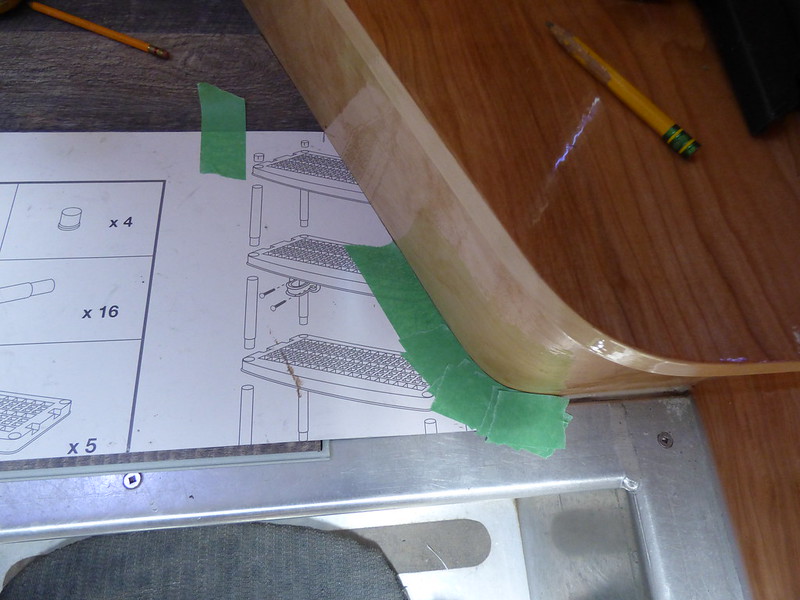

The tank repair went well, I should mention that it was only the big main water tank side that rotted, the rest were good and I did not replace any other parts, they were just filled and re epoxied for a smooth finish, this time the panel was completely sealed up with epoxy prior to assembly and all interior walls were worked smooth with many coats sanding between coats and eliminating all voids where water could sit.

Once the water tank was complete I redesigned the shoe storage making it bigger and wider.

Cleaned up the wiring, this is where the main bus bars are with some distribution points to a few items like the fridge, actuator wiring and espar unit.

Cover for the bus bars, drawers sit in front of this and just below it is the water pump , filter and expansion tank. access to the pump is easy, remove the bus cover, lift the big ply cover and there you go, a good sized area not shown but holds a spare water pump.

Looking at the top lifting electrical distribution site, from here wiring goes to the actuators and controls, again this is cleaned up and its bus bars are covered up. Drawers sit in front of this too.

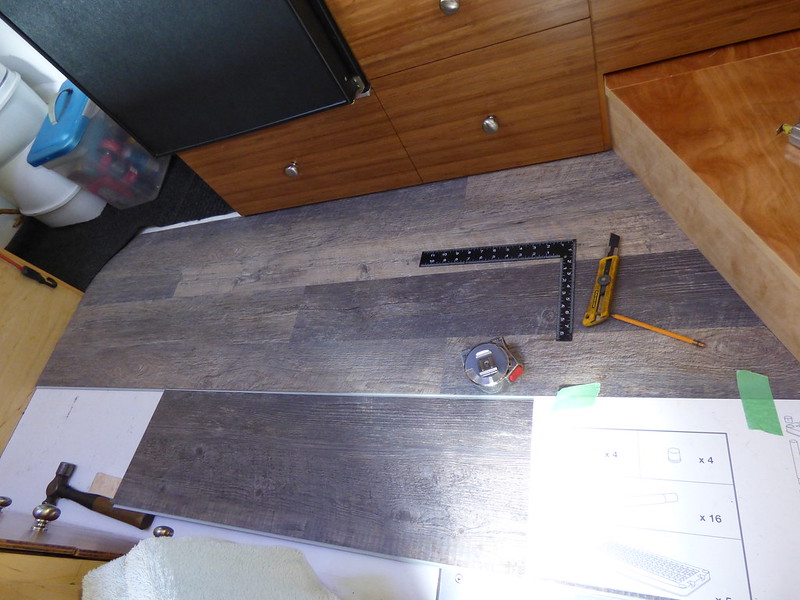

To repair the tank I removed the bed supports and everything else in the front half of the camper, so putting it back together was fun to slightly modify and improve things, this was simply a panel that goes under the bed that cuts the storage area in half but still has holes and gaps for some of our long stuff, it helps to keep stuff from moving around, ahh those simple things that make all the difference!