Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pass through/walk through /crawl through?

- Thread starter farley

- Start date

SkiFreak

Crazy Person

I'm confused... do you have a Fuso, or have you ever seen one? All of the single cabs tilt. Technically, the dual cab can tilt as well, but not without a crane, or some other form of lifting mechanism.What cab is that? and is it tilt forward? if so how do you deal with that?

And with the moving subframe, how are you making adjustments for that?

Also, if you read an earlier post of mine in this thread there is an image of the bellows which also shows the over centre clamps that release it.

I know about the bellows. I have a Fuso. Still the merge of the cab - habitat engineering is still not understood, especially with two factors

1) tilting cab and reseating with habitat when lowering the cab tilt

2) during frame twist, using spring suspended subframe, the cab - habitat movement can be so drastic the bellows could not accept that movement

What about the clamps?

1) tilting cab and reseating with habitat when lowering the cab tilt

2) during frame twist, using spring suspended subframe, the cab - habitat movement can be so drastic the bellows could not accept that movement

What about the clamps?

SkiFreak

Crazy Person

The bellows has a bit of spring back, so it pulls back slightly when the retaining clamps are undone.1) tilting cab and reseating with habitat when lowering the cab tilt

That along with the cab tilting on an angle when opened allows for the freedom to clear the bellows and the cab.

If you have a drastic amount of movement between the camper body and the chassis then the design is not correct. You need stronger/more springs.2) during frame twist, using spring suspended subframe, the cab - habitat movement can be so drastic the bellows could not accept that movement

You should not have more than about 30mm of separation between the chassis and the subframe at any time.

Contrary to what many people believe, a kinematic mounting system on a Fuso is not intended to completely remove stresses from articulation, it's just to reduce the twisting of the habitat to the point that it does not do damage to things like internal furniture and fitouts.

If the chassis is allowed to flex unrestrained it will do as much damage, if not more, than if the habitat were hard mounted to the chassis.

A spring mount system will allow the chassis to flex along its length, whereas a fixed mount system will focus the flexing, normally just in front of the chassis step, which can be problematic in offroad scenarios where there is a lot of articulation.

The Fuso chassis is designed to flex and that flex is an integral part of the suspension system, but you do need to limit the amount of flex, or the chassis will likely fail from over twisting.

If the separation between the chassis and subframe exceeds 30mm (or so) then you will likely pop the bellows sock out of the cab, or do damage to it. The amount of acceptable sock movement will also be determined by what material you use. Some people use rubber bellows and other use a similar material to that used for pop-tops. Each has its plusses and minuses.

30mm may not seem like much, but remember, this is at the chassis rails, which are only 650mm apart. There is much more movement at the outside edge of the camper body.

When I look at your subframe picture, I like the simplicity

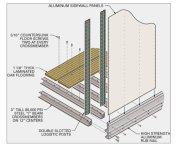

I'm considering using a 16ft reefer box. (then remove the rear door, and fabricate the departure angle so the on frame length is 14ft). The reefer box comes with 3 inch insulation using FRP in the interior.

This has steel I-beams under the floor.

Welding theses i-beams to the subframe rails should save me from any additional height.

Any comments?

I'm considering using a 16ft reefer box. (then remove the rear door, and fabricate the departure angle so the on frame length is 14ft). The reefer box comes with 3 inch insulation using FRP in the interior.

This has steel I-beams under the floor.

Welding theses i-beams to the subframe rails should save me from any additional height.

Any comments?

Attachments

Last edited:

SkiFreak

Crazy Person

Not really, as there are too many variables.Is there any spec for the spring size on the subframe ?

I took a "best guess" approach when it came to my springs, working on the theory that I could always replace them with softer or firmer springs, if required.

I should add... I have been working with steel and fabricating stuff for the majority of my life, so I would like to think that I made an educated guess, not just a stab in the dark.

You should also be mindful of creating cold bridges, as they can lead to undesirable condensation issues inside a camper.

SkiFreak

Crazy Person

My passthru setup is the reverse of the pictures you posted. On mine the fixed portion of the bellows is on the camper body.For the passthrough, I will design two boxes that integrate with the bellows.

This reduces the weight of the cab, which helps when tilting it.

These guys do it all: https://www.motorcraftoa.com/

They are building my habitation box at the moment, haven’t got to the crawl through yet so can’t send pics.

They are building my habitation box at the moment, haven’t got to the crawl through yet so can’t send pics.

Similar threads

- Replies

- 27

- Views

- 1K

- Replies

- 0

- Views

- 1K

- Replies

- 7

- Views

- 2K

- Replies

- 28

- Views

- 3K