harrisonrmatt

Member

Being in Florida, we make many beach runs and dive trips throughout the year. Running water to wash off salt, sand, sunscreen lotion, and gear has long been on my to do list. I finally got around to this project, with a different approach than I have seen most others take – which is why I am posting as others may find this as a good alternative.

Most folks I find mount their pump under the Jeep where it is exposed to the elements. According to the product description for the pumps I looked at (and the pumps I see most commonly used in this application), are not really meant to be mounted outside. My take on this will shift the pump location to the interior.

Primary Objectives:

Two things I initially planned for but am omitting for now are a drain plug for the bumper and a strainer on the pickup line.

I may at some point change the tank from the factory rear bumper to something removable – or – something that expands the capacity of the factory bumper. This might be:

Design:

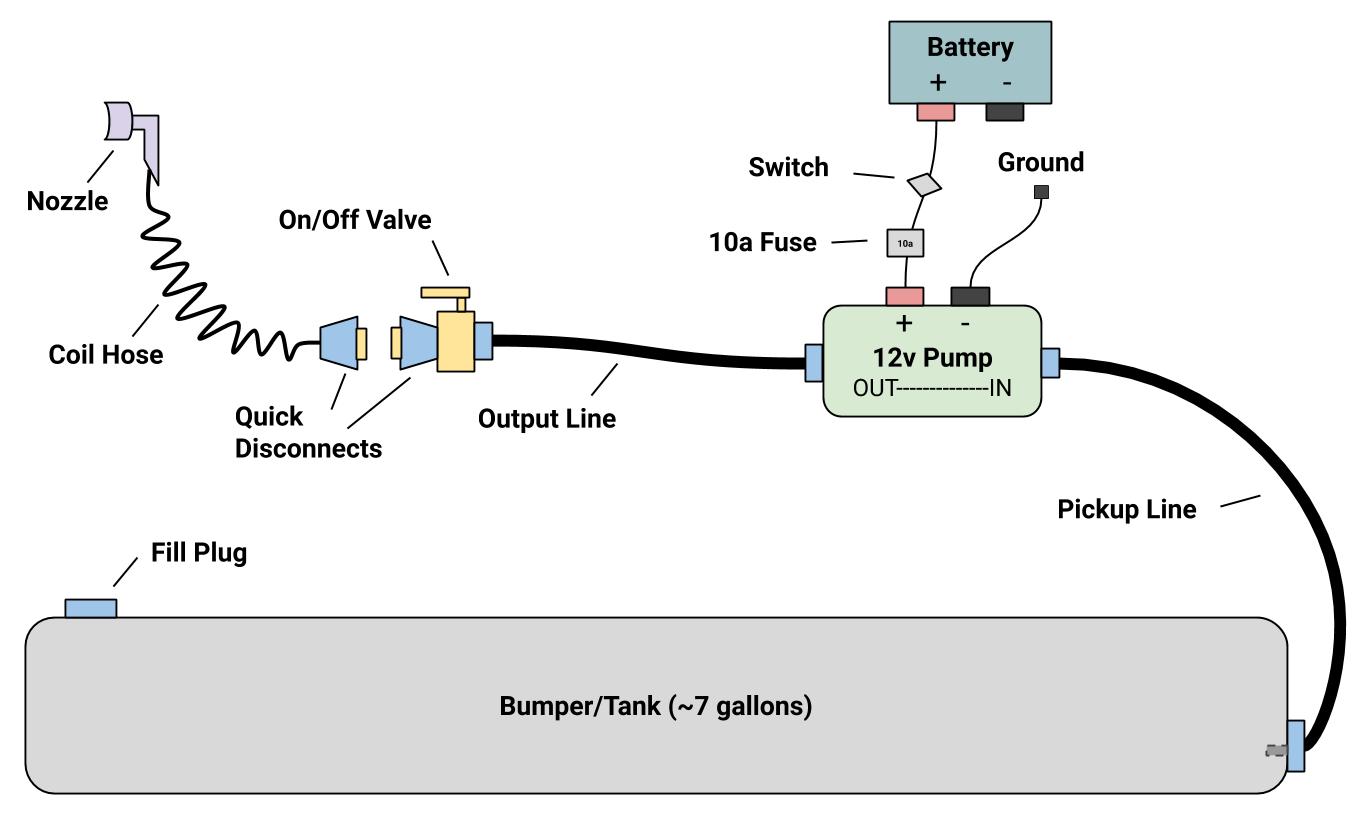

Here is the general design of the system.

The two unique elements to my iteration of this, as compared to the others that I have seen, is the location of the pump (being in the interior) and the location of the spigot (being on the driver’s quarter panel, but not requiring any cutting or drilling).

The pump will be located in the factory Alpine subwoofer enclosure. Long ago I built a sub enclosure for under the driver’s seat, freeing up the space in the factory sub location. I never replaced it with the sub delete panel, and it turns out the Flojet pump I am using fits perfectly in the empty cavity where the factory sub once was. This allows for a factory-like appearance, and does provide some airflow for the pump through the factory sub grill cover. I don’t believe the pump will ever run long enough to overheat, but our summers in Florida can be quite hot. It also allows for easy access to the pump if I ever need to troubleshoot or replace parts.

Another unique advantage I have is with the location of the spigot. I broke the factory license plate bracket a while back and have since installed the JKS license plate relocation bracket to the spare tire. This opens up a really perfect location for the spigot on the driver’s side, using the factory license plate bracket mounting location. I made a fiberglass copy of the JKS curved metal plate cover which will allow for easier drilling of the hole for the hose fitting, and attaching the hose valve on the exterior of the panel cover. You can pick up just the bracket on Amazon for around 15 bucks from other manufacturers.

The basic summary of the design is as follows:

Once I am done I can post a complete list of materials and equipment. For now, here is what I have:

Wiring

Most folks I find mount their pump under the Jeep where it is exposed to the elements. According to the product description for the pumps I looked at (and the pumps I see most commonly used in this application), are not really meant to be mounted outside. My take on this will shift the pump location to the interior.

Primary Objectives:

- Reliable pressurized running rinse water.

- Clean, factory-like appearance.

- Reversible (no permanent changes to the body/tub).

- Spigot and fill locations on the driver’s side (my garden hose at home is located on this side, and the spigot will be easier to use when the tail gate is open if it is on driver’s side).

- Modular in that I can relocate the reservoir (see below).

- Limited carrying capacity of the factory bumper.

- Low/limited water pressure from the system.

Two things I initially planned for but am omitting for now are a drain plug for the bumper and a strainer on the pickup line.

I may at some point change the tank from the factory rear bumper to something removable – or – something that expands the capacity of the factory bumper. This might be:

- An external tank that is strapped in the rear cargo area, that can either feed directly to the pump, or refill the rear bumper.

- Fiberglass water reservoirs above each rear tire well (space that is otherwise unused) that feed into the rear bumper, expanding its capacity.

- A roof rack mounted reservoir that feeds into the rear bumper or feeds directly to the pump.

Design:

Here is the general design of the system.

The two unique elements to my iteration of this, as compared to the others that I have seen, is the location of the pump (being in the interior) and the location of the spigot (being on the driver’s quarter panel, but not requiring any cutting or drilling).

The pump will be located in the factory Alpine subwoofer enclosure. Long ago I built a sub enclosure for under the driver’s seat, freeing up the space in the factory sub location. I never replaced it with the sub delete panel, and it turns out the Flojet pump I am using fits perfectly in the empty cavity where the factory sub once was. This allows for a factory-like appearance, and does provide some airflow for the pump through the factory sub grill cover. I don’t believe the pump will ever run long enough to overheat, but our summers in Florida can be quite hot. It also allows for easy access to the pump if I ever need to troubleshoot or replace parts.

Another unique advantage I have is with the location of the spigot. I broke the factory license plate bracket a while back and have since installed the JKS license plate relocation bracket to the spare tire. This opens up a really perfect location for the spigot on the driver’s side, using the factory license plate bracket mounting location. I made a fiberglass copy of the JKS curved metal plate cover which will allow for easier drilling of the hole for the hose fitting, and attaching the hose valve on the exterior of the panel cover. You can pick up just the bracket on Amazon for around 15 bucks from other manufacturers.

The basic summary of the design is as follows:

- The bumper fill cap will be located on the top exposed area of the bumper on the driver’s side (a common location that most who have done this use).

- The fitting for the pickup line will be located on the lower inside-facing face of the bumper on the passenger side. This seems to be the lowest point on the bumper, but that can always change with the angle in which the Jeep is parked at.

- From there, I will run hose up through the factory pass-through into the rear quarter panel (behind the taillight), and through the factory rubber grommet that passes into the interior of the Jeep on the top of the quarter panel.

- The pickup hose will then run into the upper portion of the sub enclosure panel, into the pump.

- The output line will run in parallel with the pickup line – from the pump, through the upper part of the sub enclosure, back down the factory rubber grommet, and through the factory pass out of the bottom of the quarter panel.

- From there, the output line will be run through the rear frame cross member. The hose will run up through the driver’s side quarter panel, and to the location of the factory license plate bracket where the spigot will be.

Once I am done I can post a complete list of materials and equipment. For now, here is what I have:

Wiring

- 20’ 12 AWG copper strand wire.

- Rocker switch.

- Inline fuse holder, 10 amp fuse.

- Various wire connectors, terminals, heat shrink, zip ties, wire loom.

- Flojet 03526-144A pump and extra elbow barb fitting (and mounting hardware).

- 4½” x 4½” x ½” HPDE poly (cutting board material).

- T-nuts and pup mounting hardware.

- Fill plug.

- Hose clamps.

- Rubber hose grommets.

- JB WaterWeld.

- JB Weld Epoxy.

- Fiberglass materials.

- Hoses and fittings in the order they run:

- ½” male NPT x ½” hose barb nylon elbow fitting (pickup line).

- 5’ ½” ID braided hose (pickup line).

- ---pump---

- 12’ ½” ID braided hose (output line).

- ½” male NPT x ½” hose barb brass straight fitting (output line)

- ½” female NPT x garden hose brass sillcock valve (output line)

- Brass quick disconnect hose fittings.

- 15’ coil garden hose.

- Spray gun nozzle.