The Artisan

Adventurer

Similar. What is your spacing distance? I would add some of these for dust http://www.tmhardware.com/Adhesive-Weatherstrip-Pile-Brush-for-Glass-Sliding-Doors.html

Kevin

Kevin

Similar. What is your spacing distance? I would add some of these for dust http://www.tmhardware.com/Adhesive-Weatherstrip-Pile-Brush-for-Glass-Sliding-Doors.html

Kevin

I saw another build on this forum with a set of brushes in the upper edge of the bottom camper half.

I think the build is called "out with the old in with the new" or something like that.

Sent from my iPhone using Tapatalk

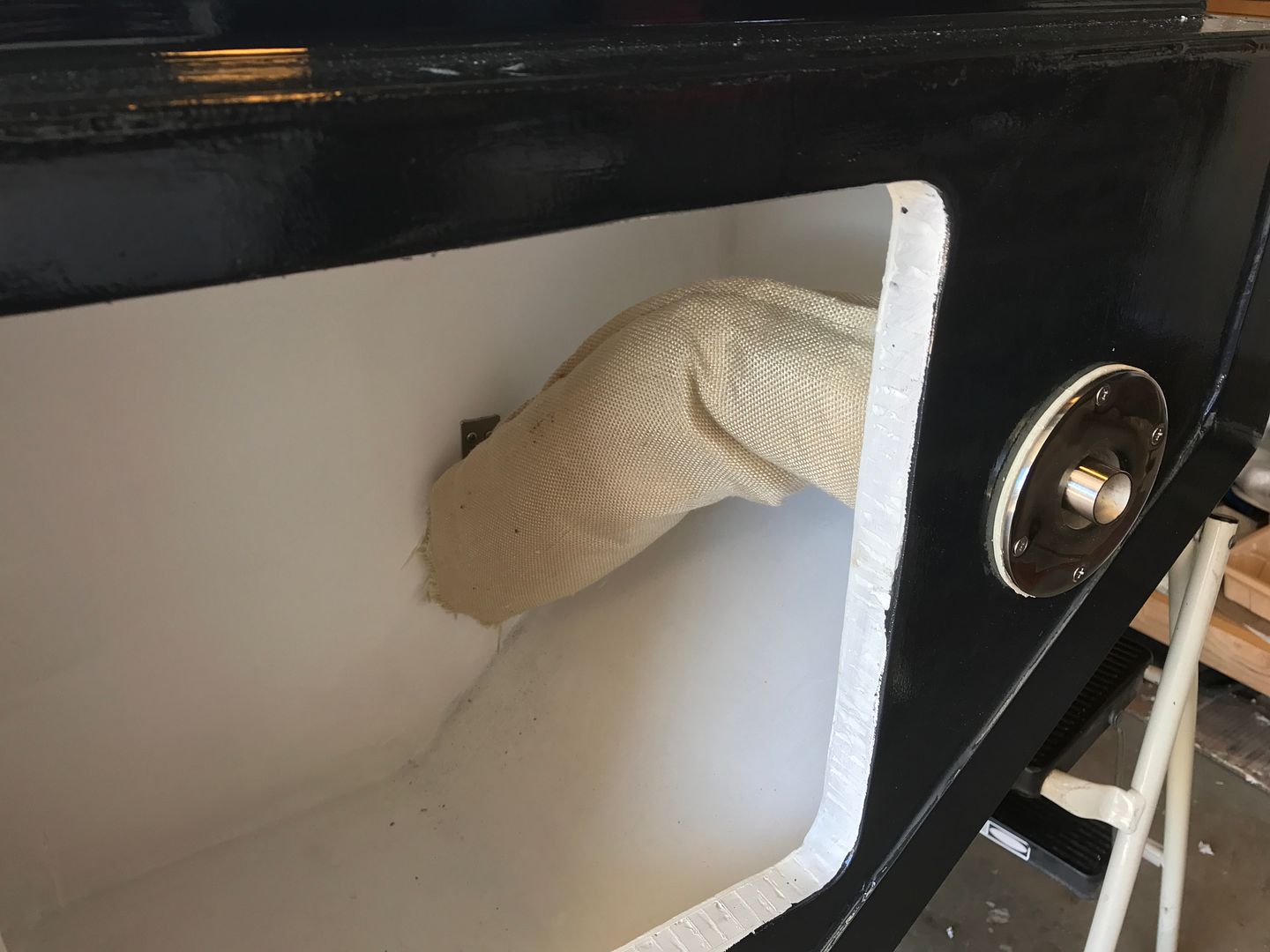

Ahhh, I was thinking about the seal at the bottom for when the slide-up is down (what my photo shows), not sealing the gap between the walls.

For sealing the gap between the walls when the slide-up is up, I have a couple plans which defy description. It's high on my list of next things to do so stay tuned. I have a variety of gap widths (by design). 1-3/8" front and rear - this seal will also limit the upward travel of the slide up. 1" on the sides and 2" on the sides where the windows are - makes sealing when in the up position a bit of a pain on the sides.

I like that seal ramdough, thanks for posting. Yeah, I know the thread you are talking about. IIRC, he rejected a brush-only seal at some point but I don't remember seeing this one. Could work for me on the sides. No idea where to find it though. Wonder if he made it out of two different seals? Anyone know what it is called or where to get it?

Few updates on other issues to follow...

Java you can see my design here

Kevin

I think he had a link for the brushes in his thread. Also he added the foam as a custom feature. The detail was buried in the thread if I recall. I had to read it a few times to grasp all that he did. The foam strip was something he added. Also, he used the spring clips from house window screens to maintain pressure evenly on the brushes.

Sent from my iPhone using Tapatalk

I think I get what you're doing there. I like it. Super clever lifting mechanism too in the lower part of the image (I think I see how that is working).

I'll have to dig deep in to the westyss thread again. I remember following it way back when but then fell too far behind and missed a lot.

Hmm, all this has me re-thinking my approach to sealing in the up position. This will keep me up at night for a while...

Hahahaha...... you suffer from project insomnia too?

I looked at copying westyss for a while, then started leaning toward a fixed roof.

He had 6 stainless roller slides where 2 were on the front, back, and left (or right) side to maintain the gap for the brushes. I figured some delrin or other plastic rub rails would do the job too. His thread had a link to where he bought the brushes from and how he fabbed the seals. I would think having brushes like him with the wiper foam, then a rubber bulb seal when closed would do the trick. You could also have a filtered air intake between the camper and truck and use a small fan to pressurize the camper to keep just out. That is if you want to go that far to keep it all clean inside.

You could always wait and see about the dust fan. If you don't have a dust problem.

I would try the brushes with foam backup and then a bulb seal on the bottom lip. Just what I would try.

Sent from my iPhone using Tapatalk