Betonhaus

New member

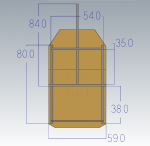

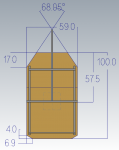

yeah they are all 2x2x.125" tube except for the little guy in the back which is 1x1x.125", but maybe it needs to be 2" also.Do you mean .125" 2" x 2" tubing? That would be much better than your channel.

As far as cross members, you need one at the axle. You should have a second one a couple of feet from the front of your frame for the tongue to tie to.

You don't need cross members to support a 1/2" floor. You're not walking on it, you're distributing your weight while laying flat.

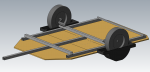

Here's a well-designed trailer frame. For your little trailer, you don't need the A-frame but you do need the box at the front to tie the tongue to.

Tony

true i can reduce the frame a little. considering the trailer is fairly short and the tongue uses a straight bar I can extend it to the axle beam, if I have only one 2x2x.125 bar that the torsion axles attack to I'm a little worried about twisting, but the bar is supported by the long bars right there so it should be fine?

And with bolting aluminum is it fine to use longer bolts that go through the whole thing or should I cut access holes so that short bolts can connect the two faces that actually touch each other? or would the plywood be not enough to give it enough twisting strength and I'll need to use brackets and such to reinforce the connections?

Last edited: