Hello, thank for the good questions.

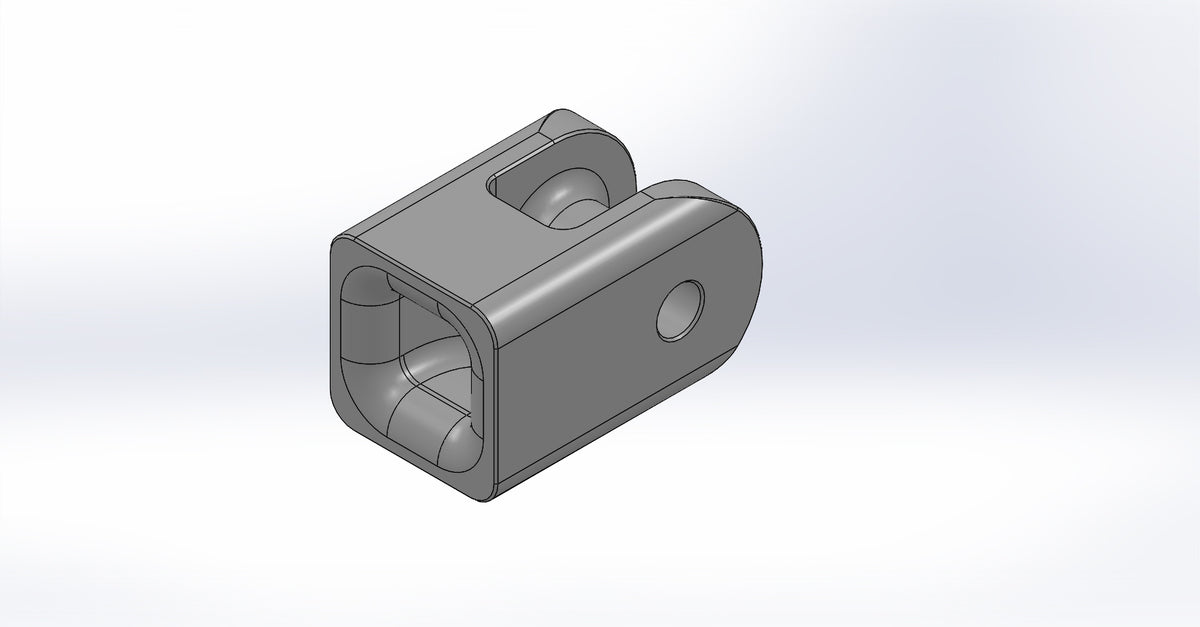

Yes, the 2.0 Version of the SSRA is pretty much maxed out with my 7/16" soft shackle with a tubular nylon guard. To fit a 1/2" soft shackle ( 4 legs worth ) through the device, you wouldn't have extra room for any abrasion guard. The 2.5 version is larger and has more room and can support up to a 5/8" leg size. The 'hole' through the 2.0 SSRA is 1" 'square' with 1/4" corner radii to prevent stress risers. The 'tube' that the soft shackle goes around that helps support the pin is 1" diameter ( on the 2.0 version ) leaving a 1/2" x 1" channel for the soft shackle to wrap around.

I size soft shackles based on the line used to construct them. My current soft shackles are built from Sampson Rope 7/16" Amsteel Blue SK-78 Dyneema. My soft shackles use an 'independent' leg design. I find this the strongest overall with the longest service life when paired with all my different products. Most of the leg is still 7/16" diameter, but where the tails are buried after coming back through the top knot, the diameter of each leg is up to 5/8" for about 6-7"

I don't love commenting on other companies devices, but I will give it a shot. F55 is a good company and builds nice quality products. If the hole is 7/8" ( typically used to support a 3/4" Screw Pin Anchor Shackle with a 7/8" pin diameter ), MY soft shackle design with independent legs, would be a very tight fit. You might be able to wiggle it through there, but you likely won't have any room for an abrasion guard. While some companies, like F55, have started to adopt some softening of the radii on the corners of these holes, they are typically the bare minimum in my opinion. I don't think you will see a long service life on a soft shackle shoved through a hole like that. You might have a little better luck getting more material through the hole with a single leg soft shackle ( where the legs are one inside each other ), you will typically see all the wear on the outer leg causing a shorter service life.

I hope that helps.