I'm just about to get started on a scratch built trailer and had a few questions that I couldn't find answers to easily.

I'm trying to determine the axle width I need and am curious: how much clearance do I need from the tire to the tub of the trailer. I'm planning to run a 3500# axle with matching weight leaf springs from a local supplier.

The other question I have is about tracking. I understand most people build their trailers so that the tires will fill the same path on a trail. How important is it to have that tracking be exactly the same? I guess I'm asking how big of a deal is it to be off by an inch or two or even a couple inches each side? What issues could or would arise from this? I don't want my tires to rub but I also don't want them to stick out super far either.

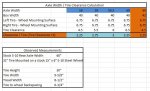

I guess I'll explain a little about the conundrum I'm having. I want the tub interior dimensions to be 48"x72". I'm using 2.5" square tube for the frame so add 5" total to the exterior width and I'm at 53" tub width. My JK axle width is 64.5" (I'm running 1.25" spacers) so if I'm trying to mimic that I'd have 5.75" sticking out from the side of the tub on each side. My stock JK rims have backspacing of 6.25 so I don't have enough clearance. If having the trailer track the same is imperative I'll shave down the tub to get things to fit but if it isn't I'll consider widening out the axle.

Thanks for the help and direction.

I'm trying to determine the axle width I need and am curious: how much clearance do I need from the tire to the tub of the trailer. I'm planning to run a 3500# axle with matching weight leaf springs from a local supplier.

The other question I have is about tracking. I understand most people build their trailers so that the tires will fill the same path on a trail. How important is it to have that tracking be exactly the same? I guess I'm asking how big of a deal is it to be off by an inch or two or even a couple inches each side? What issues could or would arise from this? I don't want my tires to rub but I also don't want them to stick out super far either.

I guess I'll explain a little about the conundrum I'm having. I want the tub interior dimensions to be 48"x72". I'm using 2.5" square tube for the frame so add 5" total to the exterior width and I'm at 53" tub width. My JK axle width is 64.5" (I'm running 1.25" spacers) so if I'm trying to mimic that I'd have 5.75" sticking out from the side of the tub on each side. My stock JK rims have backspacing of 6.25 so I don't have enough clearance. If having the trailer track the same is imperative I'll shave down the tub to get things to fit but if it isn't I'll consider widening out the axle.

Thanks for the help and direction.