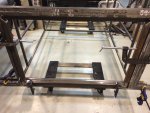

I really like the wood units (actually more than steel). I'm not real good with wood either. I needed a trailer that I could carry lots of heavy gear in, and go out with short notice without loading anything in the truck or Jeep. I have a cabin in the mountains and carry cargo up and a heavy (load) trailer would benefit us when we make a trip up there and camp with the trailer too.. My opinion is that it's way too big, and the design is very overkill, but that's what I feel was needed for our needs. If you can't tell from the drawing (not a great rendition), it's a roof top tent model with a pull out kitchen, water tanks, hot water shower, fridge, solar, awning, and LOTS of cargo room. Not insulated (not sleeping inside), but my plan is to wrap it with 1/4" sealed birch laminated with 26 ga epoxy coated roofing metal. Thanks for the interest.