My two cents..

Sorry, I just saw this thread, otherwise I would have responded sooner.

You really need a 90 degree clamp on this in my opinion. The bumper looks really nice by the way, but it was not designed with the clamp in mind.

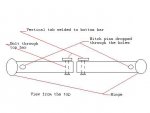

What would have been ideal is to have a gap between the two swing aways so that you could mount a 90 degree clamp at the end of each. The bad news is that you already started welding. The good news is that you can still fix this easily! From what I can see, you can cut a portion of the main bar off the end of the driver's side swing away to create that gap. Then just weld two tabs/flat hooks to the bumper and you will have an extremely solid swing away. For clamps, I would order them from Garvin Industries.

(Phone: 619-44(zero)-7415). Call them and they will explain why these are so much better than other clamps. They are a bit pricey (at $70 a pop-includes shipping I believe) but this will be the best moeny you have spent on your vehicle. (I had mine 3 days after I ordered)There is no pin to pull and you can operate it with one hand because it has a saftey catch that can be released with your thumb. We replaced both of our clamps with these on our jeeps and they are fantastic. Here are pictures of what I am talking about:

There are lots of discussions on the web about how much better the 90 degree clamps are so you don't need to take my word for it.

So basically, you would cut the bar off right where your new clamp is mounted.

Let me know if that does not make sense to you, but trust me, this is the way to go- you will not regret it.

Hope this helps.