Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Structural stability for my Camper box build and materials selection.

- Thread starter Buildingfreedom

- Start date

ExpoMike

Well-known member

TY

...that means I can't get rid of it... ?

Thing is, you want to have some flex. If things are so rigid nothing flexes, then things break and driving down any road, they are not truly flat. Get on back roads or dirt roads, it's even worse. All vehicles have flex built into them. It's about controlling the flex, that's the challenge. You build that into the design, for your use. This is why things like box trucks have some built in flex mounts (pivoting, spring captured, etc.).

Buildingfreedom

New member

Thing is, you want to have some flex.

TY again.

Thing is, tbh, I have in my mind the class c RVs, which don 't flex that way. A guy from japan solved the problem of the huge flexing cabover by installing a roof rack:

It would probably be bad for the mod's registration over the truck's paper but in this way the construction of the same camper box would be simplified, given that the cabover partially weights itself over the truck's cab, so I don't have to use beams which are that strong and heavy and even the stability of the connection of the beams is less important (I mean rivets and/or welding), but will this way-to-build make the structure more fragile as well?

ExpoMike

Well-known member

What size vehicle are you using? The one in that video is a very short wheelbase, which will limit frame flex but that is not going to be your typical camper build on a normal vehicle (like truck, box van, etc.).

Class C RV's have some flex to them. This is why over time you will start seeing cracks or interior items loosen up, from the flex. That said, most of those are never going to see a dirt road. Paved roads, in most cases, put must less strain and flex into the vehicle.

Class C RV's have some flex to them. This is why over time you will start seeing cracks or interior items loosen up, from the flex. That said, most of those are never going to see a dirt road. Paved roads, in most cases, put must less strain and flex into the vehicle.

Buildingfreedom

New member

What size vehicle are you using? ...

TY, very explicative, my bubble has just burst.

My basis will be the same vw truck of the video of the "flexing cabover" (it's a t6.1, mine is a t5 but basically they are the same van/truck, the newer has just lost a cylinder ?

Given your points, I think that the best option would be to install the box not over the bed, that should be completely removed, but instead over the 3 pins, in the same way the bigger trucks are made, with the 2 longitudinal pins placed on the frame behind the cab and the 3rd one longitudinally placed on the back of the frame (still to see if this is technically possible or lawful); I saw some travel videos with these trucks and you can see that the truck cab bends on one side while the box bends on the on the other side, ugly too see but kinda effective.

rruff

Explorer

I have a similar build going and I posted how to calculate deflection in the build thread: Expedition Portal Compact Van forum.

That's a popup, right? What does the panel underneath the cabover consist of (the one you sleep on)?

The OP is making a solid camper where the cabover is basically a very stout and short box beam. Totally different.

What do you think about the materials I should use? Which option is the best for my project?

If you care about insulation, you don't want aluminum framing that joins inner and outer walls.

What do your panels consist of? Many camper builds have been done with fiberglass sheets bonded to a foam core. You don't need framing in the panels. You can join the panels together by bonding external and internal aluminum angle on the edges. .125" thick or 3mm would be more than enough. You could also use .25" fiberglass angle rather than aluminum, and it would have the advantage of matching the thermal expansion coefficient better. No framing! It's unnecessary.

Aluminum: https://store.buymetal.com/aluminum/angle/6063-t52/aluminum-angle-6063-t52-2-2-0.125.html

2" X 1/4" Structural Fiberglass Equal Leg Angle at ePlastics

We sell Structural Fiberglass sheet and shapes

As I recall the PVC foam I used (60kg/m^3) came from Italy so you can probably buy it for a reasonable price. I paid $165 for ~48"x96" 38mm thick sheets. You may find companies that will glue the sheets and foam together and sell you panels... maybe already cut to size!... that would save a lot of work.

You may want to pay some special attention to where the bottom of the cabover meets the vertical wall behind the cab, but this isn't hard. A simple way would be to bond a larger square tube on the external portion of that junction, rather than angle. Or you could use larger and thicker angle. If you could find a triangular extrusion that would be ideal, but it might be hard to find. Add some small braces on the outer edges, and you'll be in good shape.

rruff

Explorer

Actually, i m not sure if this is because of the truck's frame bending or if it's due to the box's structural construction... what do you think?

Mostly the frame. It might also be the mounting between the frame and camper, if there are some cushions. Are these frames C-channel or boxed?

rruff

Explorer

A guy from japan solved the problem of the huge flexing cabover by installing a roof rack...

will this way-to-build make the structure more fragile as well?

it is was a fully boxed (torsionally stiff) frame, that would probably be fine. C-channel frames are intended to flex though, and if you introduce a brace, then all of that bracing needs to be strong enough to carry the torsional load of your entire rig. I suspect a weak point will break sooner than later.

Buildingfreedom

New member

If you care about insulation, you do

Hello! I want an alu box in order to have the faraday cage just in case a bolt "decides" to strike me

yep...

If I oversize of few inches (3?) the box I can pit the insulation material like armaflex.

Buildingfreedom

New member

Mostly the frame. It might also be the mounting between the frame and camper, if there are some cushions. Are these frames C-channel or boxed?

TY for this point. Didn't know about it...

It's the framed version of a regular van, which should be built in the "unibody" way, but in this case it's a boxed frame where the same original 2 members of the van are closed by other 2 members which are almost symmetric to them and welded over them.

(the frame in this pic is a cut frame from a crashed t5 truck, useful for a 3 axis conversion (where the law allows you), and it's upside down)

Dunno if it's a spot welding (but I would be over it) or something other method.

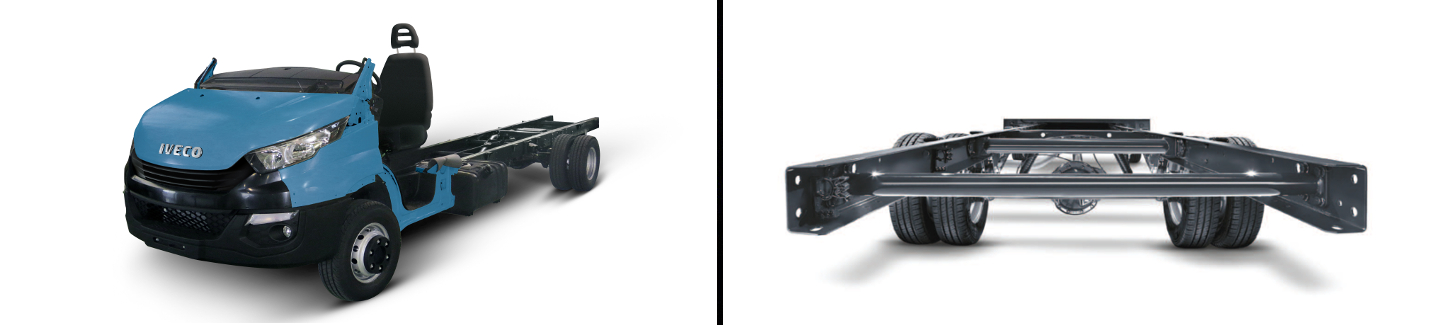

The C section frames are typical of the bigger trucks I wrote in before, the smallest and lighter of them we have here in yurop is the iveco daily:

absolutely different from my vw t5.

So, what should I be able to do with my vw?

Buildingfreedom

New member

it is was a fully boxed (torsionally stiff) frame, that would probably be fine. C-channel frames are intended to flex though, and if you introduce a brace, then all of that bracing needs to be strong enough to carry the torsional load of your entire rig. I suspect a weak point will break sooner than later.

If the vw frame should not be able to flex because it is a boxed frame, then the cabover flexing is because of the box itself and not the truck's frame flexibility, isn't it?

The vw's handbook requests 30mm of spacing between the truck's cab and the "superstructure" you want to place in there, but they don't tell you the reason, it could be a safety in case of a crash... ?

rruff

Explorer

Hello! I want an alu box in order to have the faraday cage just in case a bolt "decides" to strike me

yep...

If I oversize of few inches (3?) the box I can pit the insulation material like armaflex.

I'm not sure I understand. Armaflex is flexible foam right? What do the exterior and interior wall surfaces consist of? You can make the sandwich panels using aluminum rather than fiberglass skins if you like... but you'd need rigid foam.

So, what should I be able to do with my vw?

If yours uses boxed tubes and not C, then you probably could support the camper using the cab of the truck, but I still wouldn't. They are intended for the camper to be free standing.

rruff

Explorer

If the vw frame should not be able to flex because it is a boxed frame, then the cabover flexing is because of the box itself and not the truck's frame flexibility, isn't it?

I'm speaking of torsional flex. This is the stiffness you gain with a boxed frame vs C. Not up and down stiffness. When you see those rigs where the cab goes to the left while the camper goes to the right? Those are C channel frames with a pivoting mechanism between the frame and camper. Having a boxed frame makes your life much easier! You can mount the camper straight to the frame.

I don't think that cabover is moving that much. I wouldn't worry about it.

Buildingfreedom

New member

I'm not sure I understand. Armaflex is flexible foam right? What do the exterior and interior wall surfaces consist of? You can make the sandwich panels using aluminum rather than fiberglass skins if you like... but you'd need rigid foam.

Yep, armaflex is a soft foam, I can put (aka glue) it over the internal surfaces of the box, like for a regular van, then cover everything with whatever like wooden beads.

If yours uses boxed tubes and not C, then you probably could support the camper using the cab of the truck, but I still wouldn't. They are intended for the camper to be free standing.

My vw is a boxed tubes frame, also I forgot to say that the japanese truck of the 2nd video I posted here, has the boxed frame too.

I'm speaking of torsional flex. This is the stiffness you gain with a boxed frame vs C. Not up and down stiffness. When you see those rigs where the cab goes to the left while the camper goes to the right? Those are C channel frames with a pivoting mechanism between the frame and camper. Having a boxed frame makes your life much easier! You can mount the camper straight to the frame.

I don't think that cabover is moving that much. I wouldn't worry about it.

I see... I had just put together all the possible movements, while I should have distinguished the directions of such movements.

Also, I calculated that if I put the 3 pins, I will have to furtherly rise the box of about 200mm (8 inches) or more, which is irrelevant for something built over a real truck like a MAN 4x4 like this:

but unacceptable for a small truck like the vw that is half of its height. I can't double the original height of the truck...

rruff

Explorer

Yep, armaflex is a soft foam, I can put (aka glue) it over the internal surfaces of the box, like for a regular van, then cover everything with whatever like wooden beads.

If you want it light, strong, and well insulated, then structural sandwich panels are the way to go. All the campers you've posted on here use them.

Similar threads

- Replies

- 1

- Views

- 289

- Replies

- 8

- Views

- 1K

- Replies

- 5

- Views

- 2K

- Replies

- 16

- Views

- 2K

Forum statistics

Members online

- deeppurpleman

- CORunner

- warrpath4x4

- spfrom1973

- LandCruising'15

- stever1000

- eugene

- RatBoss

- project13support

- STREGA

- Deerhunter13171820

- Adventure1

- ljapp57

- paachi

- Cheapskate'sParadise

- zachmacgregor

- Rube2K6

- TacoTuesday603

- Gabe357

- goldrubi

- nunyabizz

- Azrunner27

- mark5280

- chevurai

- josephtoney12

- jkexp

- jhdylan

- UT_hunt'n'fish

- Jack Mac

- valcon1

- matttahoe53

- COAKXterra

- AKPacker

- El_jefe_83

- ChavyG

- brosef1848

- LoganT4r

Total: 2,485 (members: 43, guests: 2,442)