You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Camp 4x4 Bus - 1973 Suburban 8.1 Swap & Build

- Thread starter camp4x4

- Start date

camp4x4

Adventurer

Well... strike 2.

The Hedman tech suggested shorty (Hedman 62700) had a serious clearance issue with the #3 cylinder tube and the frame to the point where they couldn't even be installed. You can see in the lineup below that the 2nd tube overlaps the 1st tube... that's no good as it pushes the 2nd tube into the frame. So those are going back.

There's 3 remaining options that all seem possible but not ideal (though I think mostly still better than the stock manifold. I've taken to photoshop to do a lineup and an overlay to see the differences.

Right now I'm leaning to trying the Hedman 68618 with a quick 45* after the collector, it would be close to a long tube, but not come down so far. Second choice is to try the JBA1860S, which they also have in a ceramic coated. That one I'd be concerned with the plug wires' clearance since the tubes are so tight, though I have some heavy duty boots, so that probably wouldn't be an issue. The Sanderson are 3rd choice because they dump so straight down, which is essentially what I didn't like about the stock manifold... These do kick out more though when you look at the straight on profile, so I think they'd be ok.. that'd just be a pretty significant bend for the mid pipe to make...

What do you all think? Which would you choose?

I am going to take the opportunity, now that I'm relatively close to Summit's Sparks, NV, warehouse, to go make the return and exchange in person and check out their space. So that's kind of an up-side?

The Hedman tech suggested shorty (Hedman 62700) had a serious clearance issue with the #3 cylinder tube and the frame to the point where they couldn't even be installed. You can see in the lineup below that the 2nd tube overlaps the 1st tube... that's no good as it pushes the 2nd tube into the frame. So those are going back.

There's 3 remaining options that all seem possible but not ideal (though I think mostly still better than the stock manifold. I've taken to photoshop to do a lineup and an overlay to see the differences.

Right now I'm leaning to trying the Hedman 68618 with a quick 45* after the collector, it would be close to a long tube, but not come down so far. Second choice is to try the JBA1860S, which they also have in a ceramic coated. That one I'd be concerned with the plug wires' clearance since the tubes are so tight, though I have some heavy duty boots, so that probably wouldn't be an issue. The Sanderson are 3rd choice because they dump so straight down, which is essentially what I didn't like about the stock manifold... These do kick out more though when you look at the straight on profile, so I think they'd be ok.. that'd just be a pretty significant bend for the mid pipe to make...

What do you all think? Which would you choose?

I am going to take the opportunity, now that I'm relatively close to Summit's Sparks, NV, warehouse, to go make the return and exchange in person and check out their space. So that's kind of an up-side?

camp4x4

Adventurer

I was washing my sub today and flushing the vent area and saw this; View attachment 480487 Still had water flowing out the lower vents too.

shortbus4x4

Expedition Leader

Your Suburban is just marking its territory, perfectly normal behaviour.?

FBJR

Adventurer

I like the 618 if they will clear. Plus the ball collector allows for more give when you twist it. A good X-over will top it off.

Sold the 91 1500 for asking, then I just bought an 85 diesel which is smog exempt for the cummins swap. There it goes down by where you lived!

Now I have this and will flip the other 91 3/4!!

Sold the 91 1500 for asking, then I just bought an 85 diesel which is smog exempt for the cummins swap. There it goes down by where you lived!

Now I have this and will flip the other 91 3/4!!

Last edited:

camp4x4

Adventurer

Alright. I feel pretty good that I've exhausted all the options here (pun completely intended). I tried every header that from the previous post and they all were all pretty bad. And I can't seem to find anything elsewhere that purports to work and isn't more or less the same design as any of these.

The JBA tubes just came out way too far and almost immediately hit the frame.

The Headman 68618's kicked out too far a bit lower and ended up pointing in the wrong direction by and large.

The Headman 62700 were just wrong in every way possible, as I mentioned before.

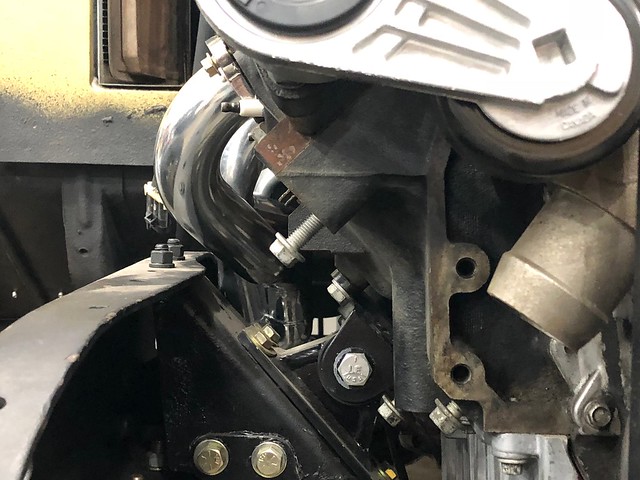

So, that left me with the Sanderson BB8 headers. These were by far the closest thing to right. They fit both sides just fine, and dumped out in places that look like they won't cause fitment issues with the rest of the exhaust system. They were a bit tight on the passenger side, but I was able to make a little bit of extra clearance in the frame with the flappy paddle. There's also a potential interference issue with the torque converter dust cover mounting tab, but I think it is manageable is I just have the exhaust guy clock the collector tube flange a different way. If that's not possible then the mounting tab can come off since there's another one near-ish that can be used instead and the whole thing should still be tight.

So, that's it. The headers are sorted.

Driver side

Passenger side

Before clearancing...

After clearancing...

Possible interference...

The other thing I've been working on is the intake. I'm gonna pursue the intake-in-the-cowl approach that I've been thinking about and take a few extra precautions to avoid water issues. The first of them is using an AEM Dryflow pre-filter. Obviously it won't particularly help with a boatload of water, but it should be enough to prevent the random bit of water that makes it down that far from particularly soaking the filter.

The second precaution I'm still kind of sorting out. It will either be a bit of the AEM Dryflow material stuck on the end of a 4" intake mounting bracket placed inside the cowl, which will create both a lip and a bit of a hydrophobic barrier that should keep most of any water out, short of a full on flooding of that space. Or I've been looking at how I could fit a 90* elbow inside the cowl that would point towards the down-slope side, thereby creating both a lip and requiring the water reverse direction in order to enter the intake. An extra bit of the Dryflow material on the end of the elbow would almost guarantee no water would enter. I think both of these would work, but I think for now I'm going to see how the non-elbow solution works.

The week before Thanksgiving should see a lot of work done on the truck. My folks are coming into town and I have the whole week off, so my dad and I should have at least a couple days of solid work. I believe one of the goals will be to get the thing to fire up... but we'll see.

camp4x4

Adventurer

Nice choice and looks good. I would cut off the flange and use a ball joint flange there as that motor will twist!

Look what I just got; No smog ever!

That's awesome.

As for the flange, I'll probably stick with the flat flange and use Sanderson's copper gaskets, then add a flex pipe right on the other side of the flange. Maybe throw a v-band on either end of that to make swapping it down the road easier.. IDK... we'll see what the exhaust guy suggests.

Ouiwee

Observer

It seems after all you might not have to do this...

The materials alone cost well more than really good ceramic coated headers. Plus days of fabrication, fitting, refitting, cussing, beering, and time at the vertical mill. That is not to mention the $400-$800 to get them finish welded correctly. They fit like a glove, but man it is nice to buy them ready made.

The materials alone cost well more than really good ceramic coated headers. Plus days of fabrication, fitting, refitting, cussing, beering, and time at the vertical mill. That is not to mention the $400-$800 to get them finish welded correctly. They fit like a glove, but man it is nice to buy them ready made.

camp4x4

Adventurer

It seems after all you might not have to do this...

View attachment 483341

The materials alone cost well more than really good ceramic coated headers. Plus days of fabrication, fitting, refitting, cussing, beering, and time at the vertical mill. That is not to mention the $400-$800 to get them finish welded correctly. They fit like a glove, but man it is nice to buy them ready made.

Those are GORGEOUS!

camp4x4

Adventurer

Cool video, is that the new place? Router, lots of lights and still cleaner than my garage.

So is that the spectre air cleaner? Been looking to do similar on mine but still want AC.

Yep, new place. Have done a decent amount of tidying up, but there's a fair bit more to do... eventually...

And yeah, that's the Spectre air box. kind of big, but not excessively so. The Vintage Air kit is on its way, so I'm going to wait for that before I go cutting holes so I can see exactly what I'd need to modify on that block off plate.

Similar threads

- Replies

- 0

- Views

- 354