The EAS disconnect switches

I have gotten several questions about the switch I run as a cutoff for the EAS. Here is a description. I use the switch(es) when putting it on a lift, a jack, my next river crossing, or whenever my next air leak springs up so I can locate the culprit area with the system depowered... I got a little tired of pulling fuses and I like switches so this has worked out well

When I first bought the truck and started routine maintenance stuff, I noticed the annoying and scary tendency the vehicle has to shift around at the most inopportune times. Any time it seems to sense a jack lifting it, the EAS system clicks on and will drop the truck as fast as it can. Your handy land rover glovebox manual will tell you that for safety reasons the EAS will not operate with the doors open. I am here to tell you (as I am sure many others can confirm), this is NOT the case. If it wants to the truck can and will drop all corners to the bump stops with every last door open. At

best, this is a minor annoyance because you usually have to use two jacks to lift it up if you don't have a floor jack around (I did not), and it loves to trap bottle jacks because the frame will sit lower to the ground after the EAS has dropped. Discovery 3 owners get used to that weird feeling of the entire truck weight shifting on a jack by itself. At

worst, the vehicle could move in such a way that traps you or someone around the vehicle under it, which would crush/maim whatever gets in the way. I have never put myself in that position, but it has been described to me that someone just finished working under his, and as he walked away from it it dropped to the bump stops (probably would have killed him). Scary moment.

I originally checked around for ways to mitigate this behavior. A few old forum posts kept turning up again and again. (these ones,

http://www.landroversonly.com/forums/f41/lr3-air-suspesion-coil-spring-conversion-58584/, and

http://www.landroversonly.com/forums/f41/what-air-suspension-disconnect-switch-58761/, among others)

What I learned from months of casual forum digging was that three fuses (really two) control the EAS in the sense that if you pull them out, the EAS is inoperable. These are: F26E, F3E, and F35P. I would pull them anytime I had to jack up the vehicle, and they work great. With those fuses out, the truck will lift normally, not shift, and most importantly: not drop. Now I could have any mechanic or friend help me work on the vehicle without them being afraid of it moving or them breaking anything. I started to wonder how much wear and tear the pulling of fuses would be, and though I never did, I contemplated the annoyance of losing fuses during work.

When I had more time on my hands, and a few basic wiring tools, I wanted to replicate what I had heard someone had done to their D3. The guy who did it was Bruce Byer, AKA Bbyer, revered on the forums, and a veritable tech guru for Land Rover owners (namely Discovery 3 owners). He wired up a switch in the cabin that controlled the F35P fuse, which he describes as the best of both worlds since the EAS can still communicate but cannot fail or drop during normal operation. Things like sensors failing and whatnot. He did a lot of the groundwork investigating the wiring diagrams, which I later used.

You can view his gallery on the original switch here:

http://www.disco3.co.uk/gallery/thumbnails.php?album=3778.

Bruce was kind enough to answer my many questions and clarifications on photos he took, and with his help I replicated first the F35P switch, but also used that to wire a second switch, controlling F26E. He continues to use his switch, and contemplated using F26E, but the fact that it is located in the engine bay poses problems if you want to actuate it from inside the vehicle.

HOWEVER

He (Bruce) wanted to clarify: "re the F35P, stress that it does not stop all movement, just inhibits some of it, some of the time." To my mind, it works as a sort of quick-fix insurance policy, since the F26E fuse is harder to get to as a driver alone, and the F35P fuse can be actuated from the safety of the cabin and actually does not throw a critical suspension fault.

In my testing I found that the F35P switch does NOT stop the dropping behavior on a jack. This is what lead me to focus my efforts on what Bruce describes as the primary fuse for EAS, F26E. F26E provides the power to the other areas of EAS, so that in theory if you cut power in that one area you disable the whole system. It freezes the EAS in its current state, useful for lifting/jacking, and running through obstacles you don't want to drop onto: like a rock garden or a deep water area. I have pulled this fuse several times when working under the truck before, so I can attest that it does disable the system. How did I make the switch? I used old photos and references made to the F35P swich from back in 2012 to sort of figure out what Bruce did, until he actually took a closer photograph of his fuse box for me.

Materials:

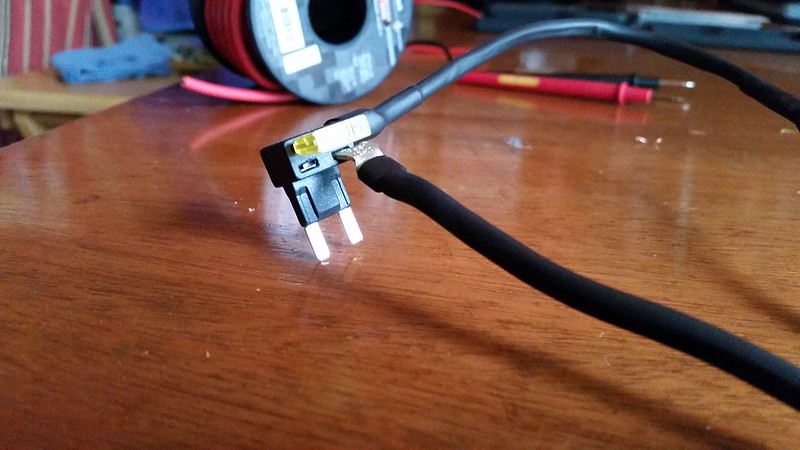

>add-a-fuse/add-a-circuit device. (example of where I got mine,

here) This is so you can add a switch to a fuse while still having a fuse in that circuit.

>Some wire. I think this was 12ga, 600V wire.

>A multimeter (for testing which way the circuit paths go)

>wire crimps

>wire terminals like these ones (you clip one prong off so that it acts like a fuse blade to complete the circuit)

>some shrink wrap

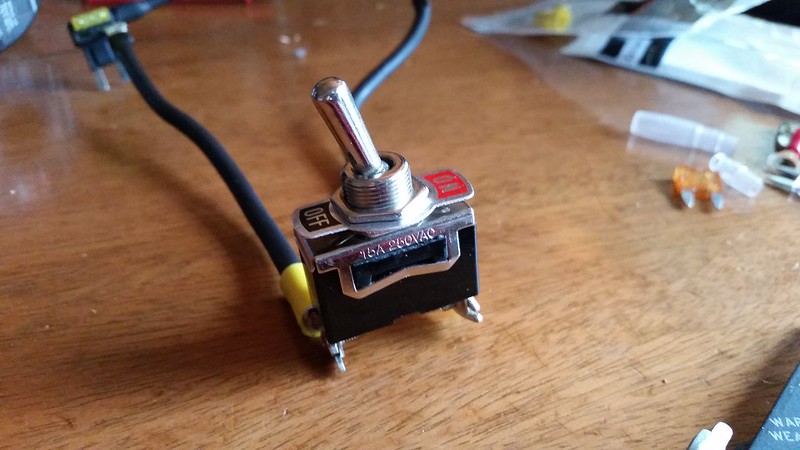

>switches (I would recommend a toggle, I looked for a 20A switch).

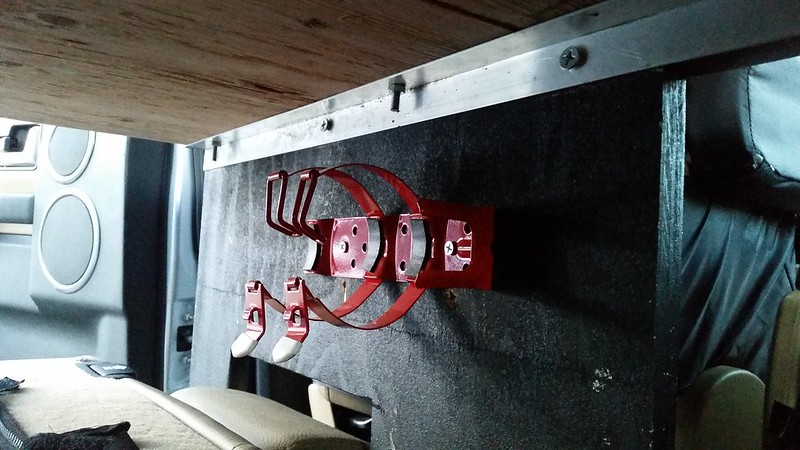

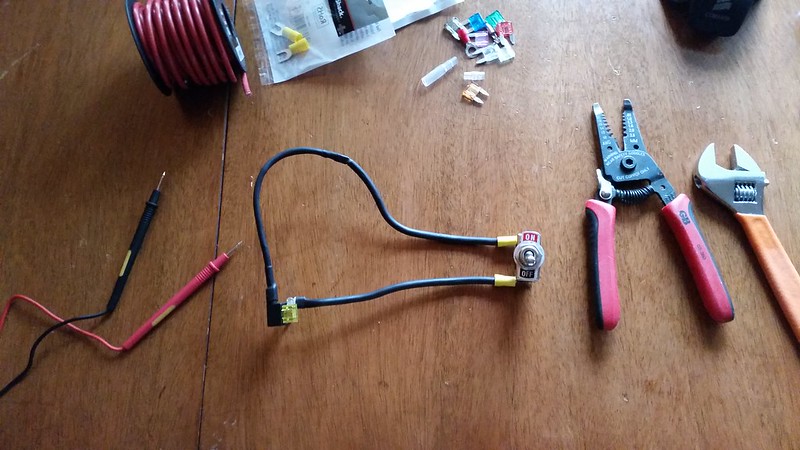

Pictured below are the two switches I rigged up. The toggle (F26E, 20A, engine bay) is the MAIN or master EAS disconnect. This I what I use when jacking up the truck or as an emergency cutoff if the system started freaking out, or to turn the system off overnight to check for corner drop (leak detection). The rocker style switch (F35P, 5A, glovebox) is the auxiliary (AUX) switch that depowers the ride height switch in the cabin and prevents errors from causing suspension faults.

Pro-tip: the add a circuit/fuse device has a wire sticking out of one side with a little crimp. The gauge is smaller than what I used so I crimped the smaller wire to my bigger wire and went on my way. Later when I was rerouting the wiring I decided to cut the little wire and splice in some more length so I could move the switch. IMO

don't do this. It is annoying to crimp a significantly smaller wire, just try to avoid messing with the existing wiring.

The rocker switch is cool but not as cool as a toggle. I ended up keeping this one around in the glovebox.

You can get a rough idea of how these things are wired up. One wire plugs into whichever slot completes the circuit. The empty fuse slot holds whatever amperage fuse you pull out and want to add a switch to.

These were both rough mock-ups of how I wanted to prove the concept out. Finished update coming.