"speak the devil's name, and he will appear!"- some superstitious medieval era Briton peasant

I had to jerk the intake off and do the stupid plenum gasket. I foiled the superstitious and nonsensical internetty claims that the bolts are simply too long and can't be properly torqued. These bolts bottom in the threads at the washers before they stop turning. So, there's that theory out the window.

I'm still looking for an Air-Gap or M1 to replace it with, so I'm not blowing 125 on the Hughes fix. It's stubborn and hopeful at the same time, but that's the horse I've chosen. I guess I'm riding it.

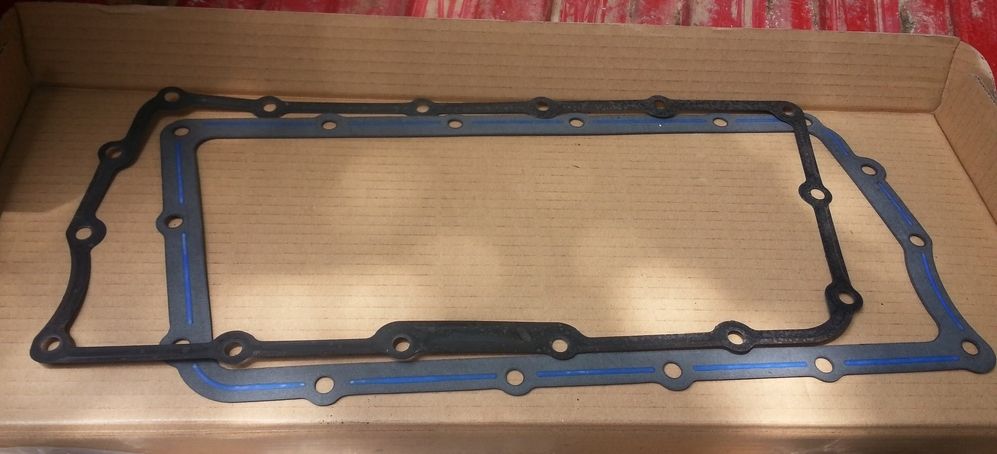

I read the FSM and the TSB on the plenum and followed the destructions for replacing the gasket. I had the Fel-Pro gasket laying around from the set I bought, and oddly never did the plenum while it was sitting around for TWO MONTHS off the truck. Boy am I stupid. El Stupido, if you're into the lingua Espana.

So, now I'm going to get some more intake gaskets and bolts, because the bolts are torque to yield. That's 30 bucks out the window. But the intake will be fixed, depending on who you ask. Hopefully the next time it comes off, it'll be getting thrown in the metal art pile.

Just for the sake of trivia, it still had the factory metal style gasket in it. Makes me think this engine is a replacement, the more I dig in an find factory gaskets and stuff on it. Or this truck is much lower mileage than I thought.

Ninjy edit!: I was standing there looking at the intake and had it all bolted up and loctited down. It occurs to me that for max reliability I should just go ahead and bite the bullet, put the alu plate on the plenum, and not have to do it again.

So, I ordered one off eBay and it'll be here in a couple of days. So, now I wait.