Nullifier

Expedition Leader

Well after my last trip to lincoln I decided to return for the motor sports 1 class. I flew into cleveland and my good friend Chris Cole of Campa picked me up. He was kind enough to lend me his awesone little trail truck for the week to drive. This truck is quite the sleeper with the strocker motor under the hood.

Unfortunetly on my first trip I lost my pics due to a hardware problem, but we have it resolved this time. This is the inside of the lincoln electric welding school area. Actually this pic only represents about 40% of the school. You do not see the area for the automated subarc welding, the many numerous classrooms, the area for oxy fuel and plasma cutting, spray welding and pipe welding stations. needless to say this place is huge and equiped with anything and everything you think of.

Here are a few pics of the plant. I was not sure about taking pics but I did get a few. They make 95% of the parts for all the welders made in the U.S in here. Including circut boards, plastic and metal panel,s genertors all of it. The pics do not do any justice to the scale of the lincon compound lol! This is my instructor Alex leading our tour.

This area is where they weld up pipe to the specs of large jobs around the world. They can simulate problems in the field here before they have to send a man out to a site.

This room is where they run generator style welders around the clock at various outputs trying to break them. The Miller units are on the other side of the room for comparison testing.

This is one of the many automated areas of lincoln assembly.

Back at my bench all students are given a thorough gas lens kit,

They also have a full on race car chassis set up which is a good discussion point for several topics relevant to tubing and tactics for getting into position to weld.

Back at my bench after I put together my Chromoly tube for the test. This is .60 wall with a threaded bung put into the end.

The aftermath of the test was a pass. Test samples must hold 11,000 lbs mine broke at 18,000lbs after six times maxing out the machine yea!

We did a lot of tubing in this class from stainless aluminum and Chromoly to alot of other specialized mig process relevant to thick material as well. I highly recomend this class if you can mig and tig already. If for nothing else then the metalurgy portions.

Back at the Campa world headquarters here are a few pics of some trailers getting ready to go out. Several with new arb fridges and tents ranging from campas own to arb and magiolinna's.

and Chris's sweet landcruiser.

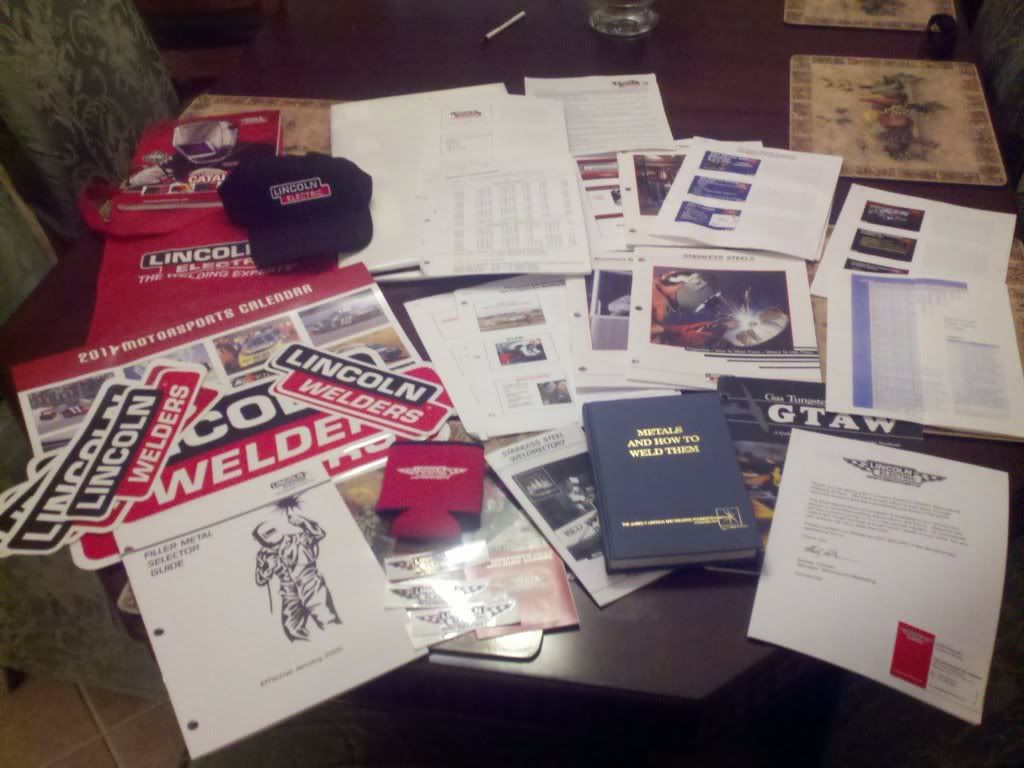

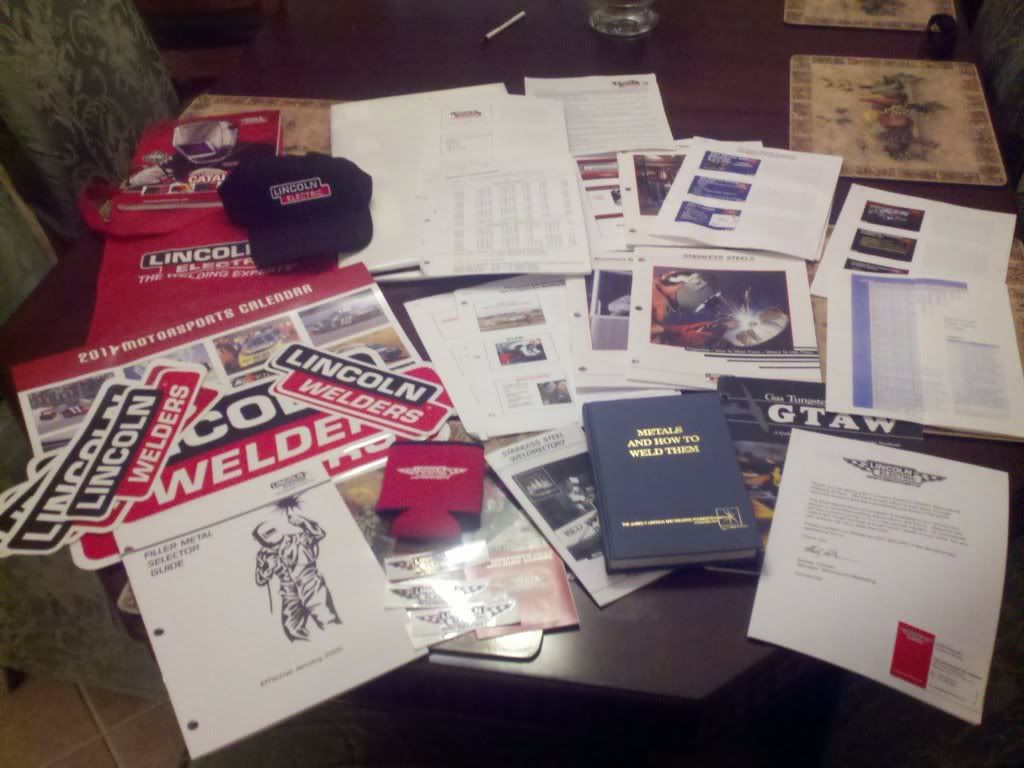

Once back home I sorted out all the technical pamphlets books and swag.

There is no way lincoln profits from the school at all. I would say they are lucky to break even which is amazing. Obviously they do it to help promote product but they do not ram lincoln down your throat. They also have really have nothing bad to say about blue machines like my millermatic and dynasty. Infact thay know that the Dynasty is a great machine.

Now after having spent alot of time on the the invertec 205 and my dynasty 200 I really can not tell a difference between the machine in use. Granted the user panel on the lincoln gets the edge and the lighter wieght and duty cycle at max output goes to lincoln but both are awesome inverter welders.

These classes and time spent have done wonders for my welding skill If you have ever thought of taking classes this is the place to do it.

Unfortunetly on my first trip I lost my pics due to a hardware problem, but we have it resolved this time. This is the inside of the lincoln electric welding school area. Actually this pic only represents about 40% of the school. You do not see the area for the automated subarc welding, the many numerous classrooms, the area for oxy fuel and plasma cutting, spray welding and pipe welding stations. needless to say this place is huge and equiped with anything and everything you think of.

Here are a few pics of the plant. I was not sure about taking pics but I did get a few. They make 95% of the parts for all the welders made in the U.S in here. Including circut boards, plastic and metal panel,s genertors all of it. The pics do not do any justice to the scale of the lincon compound lol! This is my instructor Alex leading our tour.

This area is where they weld up pipe to the specs of large jobs around the world. They can simulate problems in the field here before they have to send a man out to a site.

This room is where they run generator style welders around the clock at various outputs trying to break them. The Miller units are on the other side of the room for comparison testing.

This is one of the many automated areas of lincoln assembly.

Back at my bench all students are given a thorough gas lens kit,

They also have a full on race car chassis set up which is a good discussion point for several topics relevant to tubing and tactics for getting into position to weld.

Back at my bench after I put together my Chromoly tube for the test. This is .60 wall with a threaded bung put into the end.

The aftermath of the test was a pass. Test samples must hold 11,000 lbs mine broke at 18,000lbs after six times maxing out the machine yea!

We did a lot of tubing in this class from stainless aluminum and Chromoly to alot of other specialized mig process relevant to thick material as well. I highly recomend this class if you can mig and tig already. If for nothing else then the metalurgy portions.

Back at the Campa world headquarters here are a few pics of some trailers getting ready to go out. Several with new arb fridges and tents ranging from campas own to arb and magiolinna's.

and Chris's sweet landcruiser.

Once back home I sorted out all the technical pamphlets books and swag.

There is no way lincoln profits from the school at all. I would say they are lucky to break even which is amazing. Obviously they do it to help promote product but they do not ram lincoln down your throat. They also have really have nothing bad to say about blue machines like my millermatic and dynasty. Infact thay know that the Dynasty is a great machine.

Now after having spent alot of time on the the invertec 205 and my dynasty 200 I really can not tell a difference between the machine in use. Granted the user panel on the lincoln gets the edge and the lighter wieght and duty cycle at max output goes to lincoln but both are awesome inverter welders.

These classes and time spent have done wonders for my welding skill If you have ever thought of taking classes this is the place to do it.