rruff

Explorer

Yeah, kept it general intending to make the thread relevant to a wider group of folks, but this would be for a 2016 Toyota Tundra regular cab long bed 4x4. I expect to be living out of it most of the year, occasionally in urban areas but mostly on BLM and forest service land out west. I'm almost 6'3", hence the desire for the high cap.

Advice from someone who lived in their truck for 13 years... make the interior height tall enough to comfortably sit up straight in. That would be around 58" +- a couple. The Tundra bed is 20" as I recall (too lazy to walk outside and measure), so you need ~38" on top of that.

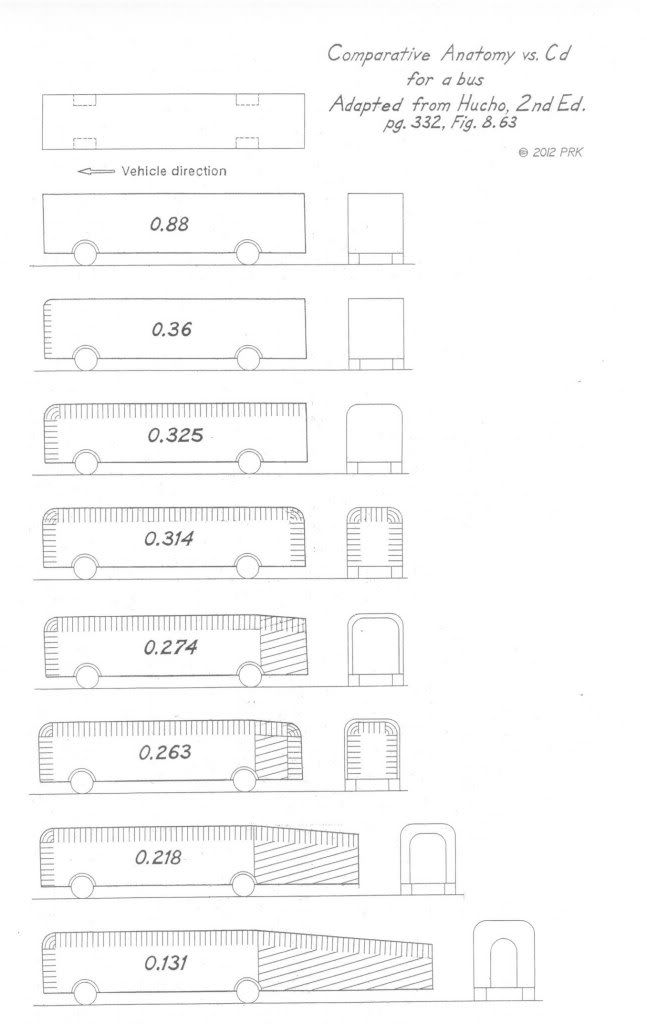

If you want to cut down on aero drag with a square box, I'd make a rounded leading edge piece out of XPS and fiberglass. Glue a couple pieces of 2" XPS together, put a 4" radius on each edge, cover with fiberglass, paint, and glue it in place. Actually, if you are handy at making things you can do the whole shell yourself. Not hard to make a box that size.

Oh, another consideration for Tundras is that the frames flex a good amount... which means your shell needs to twist.