You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weight estimation - DIY Ram 3500 with Total Composites or Box Manufaktur

- Thread starter MilesBFree

- Start date

MilesBFree

Member

Thx.

You can't get cooled seats in the single cab version of the Ram anyway, so was going to look for the cushion type accessories

You can't get cooled seats in the single cab version of the Ram anyway, so was going to look for the cushion type accessories

rruff

Explorer

I didn't read the whole thread, but one thing to remember is that 1 ton and lighter pickup (with a bed) frames are fully boxed these days, while cab-chassis models are not. The difference in torsional stiffness is pretty huge... and C-channel frames will require the cost and weight of some sort of pivoting or spring loaded subframe. So if you used a 1 ton pickup as your base you could save the cost and weight of the subframe.If I do go the 5500 route...

BTW, if you mount the camper to the frame properly, there will be little chance you'll suffer the fate of that Ram posted earlier. CG was well behind the rear axle, and the front tie-down would create a concentrated load.

Victorian

Approved Vendor : Total Composites

The arrangement of panels, hatches, etc is definitely an exercise in patience. In this regard, the assistance from our builder, Pronghorn Expedition Vehicles in building out the panel arrangement via CAD was invaluable. We are using SunPower flexible panels (100w x8) - rigid home panels are much more productive in terms of watts per square foot but heavier. Being able to run heavier panels is another 550 benefit.

A side note and plug for working with Pronghorn EV - if you choose the custom TC box route, there is no 20% tax on the panels (that is, the tariff on goods into the US from China). In addition, construction of a custom box in the US could involve substantial shipping fees. US Customs considered the completed camper as a Canadian product. The labor (labour) cost was favorable due to the exchange rate. It is not cheaper, but for us, it ended up in a higher value product to go custom built in Canada.

We included a themostatic mixing valve in our system. I'm definitely no plumber, but this should've increased our system's efficiency as it pertains to hot water usage.

An 1800W induction cooktop should be no problem - that is about the same draw as the water heater and will be on continuously for a much shorter time. We also use an electric kettle (~1400w) for coffee, etc with minimal impact. Our fridge is a 95L Dometic - it has no appreciable impact.

I agree with your analyzes about getting the custom build done in Canada if you are based in the USA. We have many customers that went that route.

On a side note: Pronghorn is no longer part of our dealer network. Please have a look at our partner listings here: www.totalcomposites.com (more partners being listed soon! )

MilesBFree

Member

I didn't read the whole thread, but one thing to remember is that 1 ton and lighter pickup (with a bed) frames are fully boxed these days, while cab-chassis models are not. The difference in torsional stiffness is pretty huge... and C-channel frames will require the cost and weight of some sort of pivoting or spring loaded subframe. So if you used a 1 ton pickup as your base you could save the cost and weight of the subframe.

BTW, if you mount the camper to the frame properly, there will be little chance you'll suffer the fate of that Ram posted earlier. CG was well behind the rear axle, and the front tie-down would create a concentrated load.

Interesting info on the difference in chassis! Did not know the cab-chassis models are not boxed.

I agree on the CG being way far to the rear. I don't know if those are small motorcycles on the back or large electric bikes, but yeah, they are creating a large moment levered way back there

MilesBFree

Member

Going back to the dually* idea as a couple of folks mentioned...

First, some info on the types and capacities:

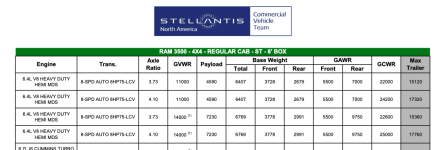

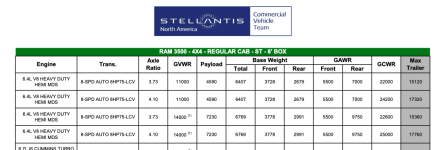

I have been looking at the D2 (pickup) type, 4x4, Longhorn (highest trim in a regular/single cab), with an 8' box.

Within D2, there are single and dual rear wheels (DRW) variants.

The following snippet from the Ram web site is where I got the 4,600lb payload and 11k lb GVWR:

The two rows with the 14k GVWR are the duallies (that is basically what the (1) footnote says if you go to the link below).

The whole thing can be found here, including the diesel sections of the tables:

https://www.ramtrucks.com/BodyBuilder/service/Image?imageId=MtQrP/FqLY5r/est8MtGjGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBFy6Od5Hdu/D

And for reference, here is the same for the DD (meaning the C/C** (cab/chassis)) versions - two PDFs since the regular and crew cabs are separate tables):

https://www.ramtrucks.com/BodyBuild...jGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBBcRdqxuHzmx

https://www.ramtrucks.com/BodyBuilder/service/Image?imageId=MtQrP/FqLY5r/est8MtGjGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBHtxZ5RVVJiE

So, going to the dually version, you add 2,640 lbs more payload. I think the spreadsheet is in the ballpark, and i am a few hundred lb over the D2 weight limits, and WAY under the dually version. Looking do-able!

Going to need to contact wheel manufacturers and see if they make or can do a super single reversible wheel in a 17 or 18". The only ones i found off-the-shelf were 20" and the wheel tire combo was like 200 lb. If I can keep the weight to not much more than I have been looking at, there are some (non-reversible) that would work. The question is can the smaller diameter wheels be built to carry the load without adding a ton of mass, i.e., keeping them around the 140lb mark for "regular" wheels?

* I am apparently attempting to use as many spellings of duallie as possible in this thread, and spell check likes none of them. Another thing to research

** yes, DD means CC

First, some info on the types and capacities:

I have been looking at the D2 (pickup) type, 4x4, Longhorn (highest trim in a regular/single cab), with an 8' box.

Within D2, there are single and dual rear wheels (DRW) variants.

The following snippet from the Ram web site is where I got the 4,600lb payload and 11k lb GVWR:

The two rows with the 14k GVWR are the duallies (that is basically what the (1) footnote says if you go to the link below).

The whole thing can be found here, including the diesel sections of the tables:

https://www.ramtrucks.com/BodyBuilder/service/Image?imageId=MtQrP/FqLY5r/est8MtGjGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBFy6Od5Hdu/D

And for reference, here is the same for the DD (meaning the C/C** (cab/chassis)) versions - two PDFs since the regular and crew cabs are separate tables):

https://www.ramtrucks.com/BodyBuild...jGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBBcRdqxuHzmx

https://www.ramtrucks.com/BodyBuilder/service/Image?imageId=MtQrP/FqLY5r/est8MtGjGgHzAHGUTU0WB3rWuqSY7YmQ2vEhuBWBHtxZ5RVVJiE

So, going to the dually version, you add 2,640 lbs more payload. I think the spreadsheet is in the ballpark, and i am a few hundred lb over the D2 weight limits, and WAY under the dually version. Looking do-able!

Going to need to contact wheel manufacturers and see if they make or can do a super single reversible wheel in a 17 or 18". The only ones i found off-the-shelf were 20" and the wheel tire combo was like 200 lb. If I can keep the weight to not much more than I have been looking at, there are some (non-reversible) that would work. The question is can the smaller diameter wheels be built to carry the load without adding a ton of mass, i.e., keeping them around the 140lb mark for "regular" wheels?

* I am apparently attempting to use as many spellings of duallie as possible in this thread, and spell check likes none of them. Another thing to research

** yes, DD means CC

Last edited:

MilesBFree

Member

The Wehring wheels are interesting. And lots of other good info in your post, thx!

They don't offer one for a 3500 but will look at them if i go to a 5500. From their FAQ:

They don't offer one for a 3500 but will look at them if i go to a 5500. From their FAQ:

Do you offer a wheel for ¾ ton and 1 ton trucks?

No. We spent months designing and testing a super single conversion wheel for F350 and Ram 3500 dually trucks. We determined that the 41” tall 335/80R20 tire that is required to maintain the full capacity of the truck is simply not a good fit for these trucks. The brakes are too small to stop a 41” diameter tire and the numerically low axle gears (3.55, 3.73 & 4.10) are too “tall” and will overstress the driveline. These trucks also do not share the widetrack front axles with their F450/F550 and 4500/5500 big brothers so the 41” tire will rub on the chassis of the ¾ ton and 1 ton trucks. This rub will not only damage the truck and tires but it will also further restrict the turning radius. We tried very diligently to create this solution but the best customer service that we can give you in this case is to simply say “No” and help you to avoid a build that does not improve your truck.

MilesBFree

Member

My time might be better spent looking at tire lifting solutions for a 5500 than looking for smaller/lighter unicorn wheels and tires  @StenchRV found a sweet solution - read their entire build thread - thank you!

@StenchRV found a sweet solution - read their entire build thread - thank you!

I am not 100% tied to the Ram trucks. I had a '99 1500 and it ran forever with minimal fuss. I called it my $150k truck since I paid like $2500 for it and drove it for close to 15 years, instead of buying a new $50k truck every 5 years as some do. The way truck prices are going I should call it my $240k truck ($80k x 3 new trucks). Plus the 1500s are kind of state of the truck art at the moment. The 3500 was kind of drifting away from what i liked about the 1500 (e.g., air suspension, swanky interior, etc.) and the 5000 would be another drift. So would also look at F550 if I make the jump.

You don't hear much at all about the GM trucks. Plus I swore i would never buy another GM vehicle after the bad experience I had with my first new car after i got out of college and could afford one. That's been 30+ years, so maybe i could budge off that hill if there was a very compelling reason, but I'm kinda dug in.

I am not 100% tied to the Ram trucks. I had a '99 1500 and it ran forever with minimal fuss. I called it my $150k truck since I paid like $2500 for it and drove it for close to 15 years, instead of buying a new $50k truck every 5 years as some do. The way truck prices are going I should call it my $240k truck ($80k x 3 new trucks). Plus the 1500s are kind of state of the truck art at the moment. The 3500 was kind of drifting away from what i liked about the 1500 (e.g., air suspension, swanky interior, etc.) and the 5000 would be another drift. So would also look at F550 if I make the jump.

You don't hear much at all about the GM trucks. Plus I swore i would never buy another GM vehicle after the bad experience I had with my first new car after i got out of college and could afford one. That's been 30+ years, so maybe i could budge off that hill if there was a very compelling reason, but I'm kinda dug in.

MilesBFree

Member

I meant that as a joke on myself, just to be clear. i spent a ton of time on the wheel/tire search  Apologies if it was interpreted differently.

Apologies if it was interpreted differently.

you don’t want to know the time measured in weeks researching the track wheels for the RX-7 to shave ounces off…

you don’t want to know the time measured in weeks researching the track wheels for the RX-7 to shave ounces off…

ReluctantTraveler

Well-known member

The 550 is available in Lariat trim and the 5500 is available in Limited - IDK exactly what "comfort and safety" options you're looking for, but it isn't as though these are only available with vinyl floors and milk crates for seats.

There is also no reason why you necessarily need to go to MPTs/G275 on super singles on a 550/5500 as long as your build doesn't eventually creep past the weight ratings. Toyo makes a 40" with a 4190lb weight rating.

The camper plus the gear you described building in your initial post will cost about $70-90k, not including labor. It could easily remain in the 3k-4k wet weight range. When mounted on a 550/5500 chassis, you'd be safely within the weight rating and with none of the issues of the 350/3500. Likewise, you don't have to commit to the truly huge and expensive MPTs or G275s if you can avoid approaching the max weight rating of the 550/5500 chassis. Then, you'd have a camper that is still a convenient size, easier to drive (due to the 550/5500's better turning radius), and much more robust.

Found this after our chat in the other thread. Gold mine, Andy!

@MilesBFree i haven’t gotten to the end of this thread yet or followed your build before this, but I’ve been going through all of these same questions, challenges, and iterations.

Curious to see where you land!

ReluctantTraveler

Well-known member

Looks like the original post your replies to is gone, but the suggestion to consider duallies in the 3500 size is one I’d not considered either.Good catch on those - will update it.

Yep, probably heavy on the cabinets as far as the wood goes, but that was before i figured out you don't need backs on the boxes and they are glued to the habitat walls. But i also didn't include hinges, pulls/locking mechanisms, and hydraulic struts for the overhead ones.

I kinda like the 8020 aluminum extrusion approach, but from what i have read that will be slightly heavier.

Actually, the Northern Lite one is pretty close to what i am considering in terms of features, so a good reference point.

I do need to go back and look at the duallie again, as you said.

Thanks again!

Similar threads

- Replies

- 5

- Views

- 572

- Replies

- 2

- Views

- 2K

- Replies

- 23

- Views

- 4K

- Poll

- Replies

- 17

- Views

- 1K