60seriesguy

Adventurer

One of the interesting features of expedition rigs on this forum is the high-level of execution of electrical modifications. While everyone should strive for a top-notch design and installation, it's scarily common to see hacked-up electrical jobs on other forums, mostly on trailered rigs but sometimes on daily drivers as well. For folks that depend on their rig's reliability in remote locations, that is not an option.

As I embark on my first new buildup in twenty years, I'd like to tap into your collective wisdom and get some advice on the best way to *safely* and *efficiently* wire up my roof rack. Below are some details:

- INTI 3/4 length expedition rack, originally designed for an FJ60 but modified to fit a 100 series

- Four front-facing lights, Hella 500s. Two have flood pattern (outside), two have driving pattern (inside). Mounted in pairs on the front of the rack

- Two flood pattern tractor lights, mounted on the rack between the front and rear doors, one on each side

- Two flood pattern tractor lights, mounts on the rear of the rack

- *If possible*, there is one more accessory I'd like to connect to the roof rack, assume its draw is similar to one light

Ideally, I'd like to have only two switches (the 100 Series is challenged for extra switch locations), one for the front four, one for the other four (with the option of a third switch for the mystery accessory). *If possible*, I'd like to have an additional (concealed) rack-mounted switch that could turn on the tractor lights from the outside of the truck, but that's not a show-stopper.

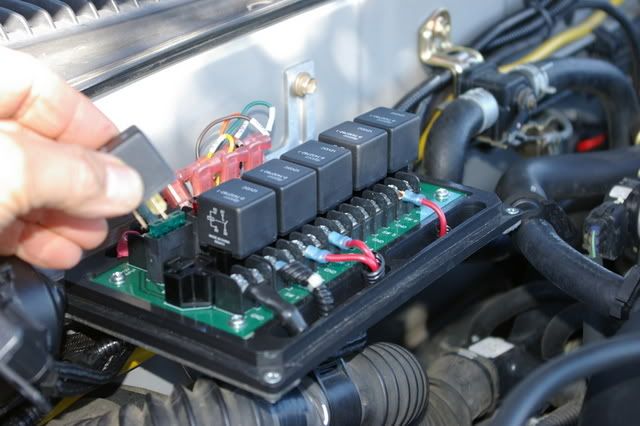

I have a waterproof junction box that will be mounted to the rack close to where the wires will come up to it and will house relays (and possibly that switch). I'm comfortable with electrical installations and will use marine-quality connectors, soldering and shrink-tubing and dielectric grease. I also plan to run all wiring through a "loom" and secure it to the roof rack. I only run the roof rack on trips, so the plan is to have everything securely mounted to it and then have only a short pigtail with a quick-disconnect to connect it to the truck.I have already solved the issue of how to run wires (not sure on how many) up to the rack cleanly and securely, so that's not an issue.

I am not 100% sure of how to design the circuit to maximize the efficient use of the lights, minimize issues. I'd love to hear some suggestions.

Also, is 10 ga. wire overkill for this application?

Thoughts? Suggestions? Comments? Graphic depictions?

As I embark on my first new buildup in twenty years, I'd like to tap into your collective wisdom and get some advice on the best way to *safely* and *efficiently* wire up my roof rack. Below are some details:

- INTI 3/4 length expedition rack, originally designed for an FJ60 but modified to fit a 100 series

- Four front-facing lights, Hella 500s. Two have flood pattern (outside), two have driving pattern (inside). Mounted in pairs on the front of the rack

- Two flood pattern tractor lights, mounted on the rack between the front and rear doors, one on each side

- Two flood pattern tractor lights, mounts on the rear of the rack

- *If possible*, there is one more accessory I'd like to connect to the roof rack, assume its draw is similar to one light

Ideally, I'd like to have only two switches (the 100 Series is challenged for extra switch locations), one for the front four, one for the other four (with the option of a third switch for the mystery accessory). *If possible*, I'd like to have an additional (concealed) rack-mounted switch that could turn on the tractor lights from the outside of the truck, but that's not a show-stopper.

I have a waterproof junction box that will be mounted to the rack close to where the wires will come up to it and will house relays (and possibly that switch). I'm comfortable with electrical installations and will use marine-quality connectors, soldering and shrink-tubing and dielectric grease. I also plan to run all wiring through a "loom" and secure it to the roof rack. I only run the roof rack on trips, so the plan is to have everything securely mounted to it and then have only a short pigtail with a quick-disconnect to connect it to the truck.I have already solved the issue of how to run wires (not sure on how many) up to the rack cleanly and securely, so that's not an issue.

I am not 100% sure of how to design the circuit to maximize the efficient use of the lights, minimize issues. I'd love to hear some suggestions.

Also, is 10 ga. wire overkill for this application?

Thoughts? Suggestions? Comments? Graphic depictions?