Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Xpedition Camper out of Minnesota

- Thread starter Hoefler

- Start date

Hate to poke but wondering what the elves have been up to lately. I need some Christmas cheer!

I do have "stuff" to post. I will take a few pictures and post them up today.

Pete

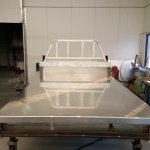

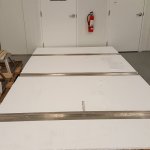

Here is where we are at. Doing a complete build for demo at Flagg in the spring.

We have the tray pak nearly finished. We have front space for small air compressor and air tanks. The heavy way rectangular tube has a drain and level sights in it as well as a fill spout-fuel or water? Have yet to explore the regulations on fuel tanks, but will claim as a fuel tank if our design fits. If not, the tank will be simply a water tank FOR WARM CLIMATES!

The tra pak has a nice compliment of boxes that will bolt on the bottom along with retractable stairs. We also have hinged removeable side boards. When the truck is not operating as a camper, it will function as a pragmatic pick up.

The photos show the camper sitting on top as well as part of our quick release secure hold downs.

Merry Christmas.

Pete

We have the tray pak nearly finished. We have front space for small air compressor and air tanks. The heavy way rectangular tube has a drain and level sights in it as well as a fill spout-fuel or water? Have yet to explore the regulations on fuel tanks, but will claim as a fuel tank if our design fits. If not, the tank will be simply a water tank FOR WARM CLIMATES!

The tra pak has a nice compliment of boxes that will bolt on the bottom along with retractable stairs. We also have hinged removeable side boards. When the truck is not operating as a camper, it will function as a pragmatic pick up.

The photos show the camper sitting on top as well as part of our quick release secure hold downs.

Merry Christmas.

Pete

Attachments

We have experimented quite a bit on the layout. First tries has a rear horseshoe shape with 24" deep cabinets. Seemed logical and a path that has been chosen by others frequently. Found that sitting in the way back produced a disconnect from the outdoors. Further, the 24" deep cabinets proved way to deep.

So, adding the rear bump out provided us a lot more flexibility with interior layout. We have made a permanet "bed" in the back for day sleeping. It sits atop a large storage space. Made a simple side dining area with more storage underneath. Reduced most of the kitch to 18" deep which has made the interior feel bigger. With the dining zone close to access door, the outdoors appears more indoors.

We are saving the rear wall for later. Engineering is working on a rear bump out made from tent material. Wide enough for a 30" wide mattress. We are hoping this will really open up the inside when at camp.

The new layout also enabled us to place more windows on sides of camper for more natural lighting.

We have purchased a new large bed cnc router. This enables us to make our own interior furniture. This alone will provide the flexibilty to explore lots of subtle changes to get the inside right as well as making it possible to do custom layouts.

Pete

So, adding the rear bump out provided us a lot more flexibility with interior layout. We have made a permanet "bed" in the back for day sleeping. It sits atop a large storage space. Made a simple side dining area with more storage underneath. Reduced most of the kitch to 18" deep which has made the interior feel bigger. With the dining zone close to access door, the outdoors appears more indoors.

We are saving the rear wall for later. Engineering is working on a rear bump out made from tent material. Wide enough for a 30" wide mattress. We are hoping this will really open up the inside when at camp.

The new layout also enabled us to place more windows on sides of camper for more natural lighting.

We have purchased a new large bed cnc router. This enables us to make our own interior furniture. This alone will provide the flexibilty to explore lots of subtle changes to get the inside right as well as making it possible to do custom layouts.

Pete

Attachments

We have begun installing the sides on the frame. For this job we have chosen Sika 252 adhesive. The frame got a random da sandinging, then activator was applied. We went one step further and used Sika primer to ensure good adhesion.

We chose this route over welding for a couple of reasons. Aluminum can crack over time. With flat sheets glued over entire frame, the panels act as a structural member, thereby reducing the chance of a crack. We chose .190" thick aluminum for the exterior panels-dent resitant and structural. Further, we have seen the results of welding aluminum sheets over aluminum members. Its always leaves a "tatoo" on the exterior panel. It warps the panels as well. Gluing the panels to the frame eliminates this and leaves a nice smooth finish that will show better than fiberglass.

Note: the rear overhang is designed to reduce the low pressure zone at the rear wall off camper when speeding down the highway.

Pete

We chose this route over welding for a couple of reasons. Aluminum can crack over time. With flat sheets glued over entire frame, the panels act as a structural member, thereby reducing the chance of a crack. We chose .190" thick aluminum for the exterior panels-dent resitant and structural. Further, we have seen the results of welding aluminum sheets over aluminum members. Its always leaves a "tatoo" on the exterior panel. It warps the panels as well. Gluing the panels to the frame eliminates this and leaves a nice smooth finish that will show better than fiberglass.

Note: the rear overhang is designed to reduce the low pressure zone at the rear wall off camper when speeding down the highway.

Pete

Attachments

Traypak is nearly finished. The rails that support the tray off the truck frame are constructed of aluminum. They are bolted to the bottom I-beams of tray. Clip angles for the spring mounts will be bolted on to the two rails.

The other photo shows the bottom side of roof system. The roof is built from a 1" square tube frame lattice. 1/4" sheet is sika flex glued, then screwed to the frame. 3M 78 adhesive is then sprayed onto the sheet. Foam panels are layer on top of the sheet. We then screw in three wide electrical chase ways that also press down on the foam panels. When finished, the ceiling will have either maple or birch plywood or aluminum secured to the foam. A panel with lights will then screw onto the electrical chase way. This will produce a flush ceiling system that allows for easy access to wiring.

Pete

The other photo shows the bottom side of roof system. The roof is built from a 1" square tube frame lattice. 1/4" sheet is sika flex glued, then screwed to the frame. 3M 78 adhesive is then sprayed onto the sheet. Foam panels are layer on top of the sheet. We then screw in three wide electrical chase ways that also press down on the foam panels. When finished, the ceiling will have either maple or birch plywood or aluminum secured to the foam. A panel with lights will then screw onto the electrical chase way. This will produce a flush ceiling system that allows for easy access to wiring.

Pete

Attachments

Progress

Roof-cieling is finished and installed. Electrical trays run from side to side to allow for electrical wiring. The trays will have light bars attached over them allowing for ease of access to all wiring. Trays also prevent wire chafing and also allows for future electrical additions.

The roof will has insulation on bottom side and will get another layer on top before roof plates go on.

The front cab over installed easily.

Next up will be coating the interior with Lizard Skin ceramic heat barrier material. Once finished with that, the windows and doors will be installed, followed up by internal insulation and wall panels.

Pete

Roof-cieling is finished and installed. Electrical trays run from side to side to allow for electrical wiring. The trays will have light bars attached over them allowing for ease of access to all wiring. Trays also prevent wire chafing and also allows for future electrical additions.

The roof will has insulation on bottom side and will get another layer on top before roof plates go on.

The front cab over installed easily.

Next up will be coating the interior with Lizard Skin ceramic heat barrier material. Once finished with that, the windows and doors will be installed, followed up by internal insulation and wall panels.

Pete

Attachments

Finished Traypak fabrication. The vehicle has a Curt heavy duty trailer hitch on it which places the ball in a good position for trailer hook up with Traypak installed. What is not shown is the lower boxes. We have chosen to bolt these on as opposed to integration. Should a box get damaged, it can be easily replaced. Bolting on allows for specific configurations as well.

Tested our roof system and fount it to be to heavy and complex. It proved to be a bit flappy as well. We have since went to a welded grid roof system that is rigid, no flappage and can be walked on.

Pete

Tested our roof system and fount it to be to heavy and complex. It proved to be a bit flappy as well. We have since went to a welded grid roof system that is rigid, no flappage and can be walked on.

Pete

Attachments

Interior was finish coated with Lizard Skin ceramic barrier coating. Partial floor, entires walls and ceiling now have a minimum 40 mill coating. This material prevents thermal transfer. External heat or cold transfer is greatly reduced when this coating is applied. One photo shows the bottom side of our shower pan coated with this material as well.

The roof exterior will be coated in white Lizard Sking next.

Pete

The roof exterior will be coated in white Lizard Sking next.

Pete

Attachments

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 1

- Views

- 806

- Replies

- 21

- Views

- 13K

- Replies

- 1

- Views

- 2K