Yea it seems the ones I build them for, never seem to post much on here. No complaints or compliments. I guess that is okay, it is theirs. I become pretty close friends with them, and camp with them. Mine draw a different group than most on here it seems. Older guys, that are getting more into being comfortable. I will keep you in the loops silver.

DT, I think maybe you have missed the opportunity. I think this will be my last one like this. I am looking at Aframes and a four sided idea for folding trailer.

I like to be able to stand up inside, cook inside is easier for the wife. I am not sure. I am supposed to build two more, but one put off until December and the other does not want to move up. So I have 3-4 months of not doing much. I do not take deposits until I am ready to start their build, so who knows they may change their minds and I might change mine.. Just do not like holding on to someone's money like that. I know all the others do, but I don't.

I will be riding my bike, will have more time to train for the Senior Games in October. Adding 400 meter free style to the cycling and mountain biking this year. Had to give up the track sprints with the knee replacements. But can do swimming no problem. I used to swim that in the Marine Corps, so will see how it turns out.

The wife thinks I am crazy for doing this at all. She says, your retired, worked your whole life, go play. Not sure I am capable of that yet. But may consider it. lol

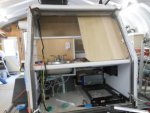

Just finished one sliding door, very tight. A little concerned but I made these different, you have to unscrew the bottom rail to remove them. Will try some graphite and see what happens, may have to take it back off and sand it down some. I had wanted to use 3M emblem tape, but just can not get it to work. Works great on the top, but gets stuck going in and can not get the door straight. Oh well, ideas, got millions of them, wish more worked!!!!!