Sep 12, 2021 at 10:13 PM

More progress this week/weekend. Although, like the last few posts, not as much as I am hoping.

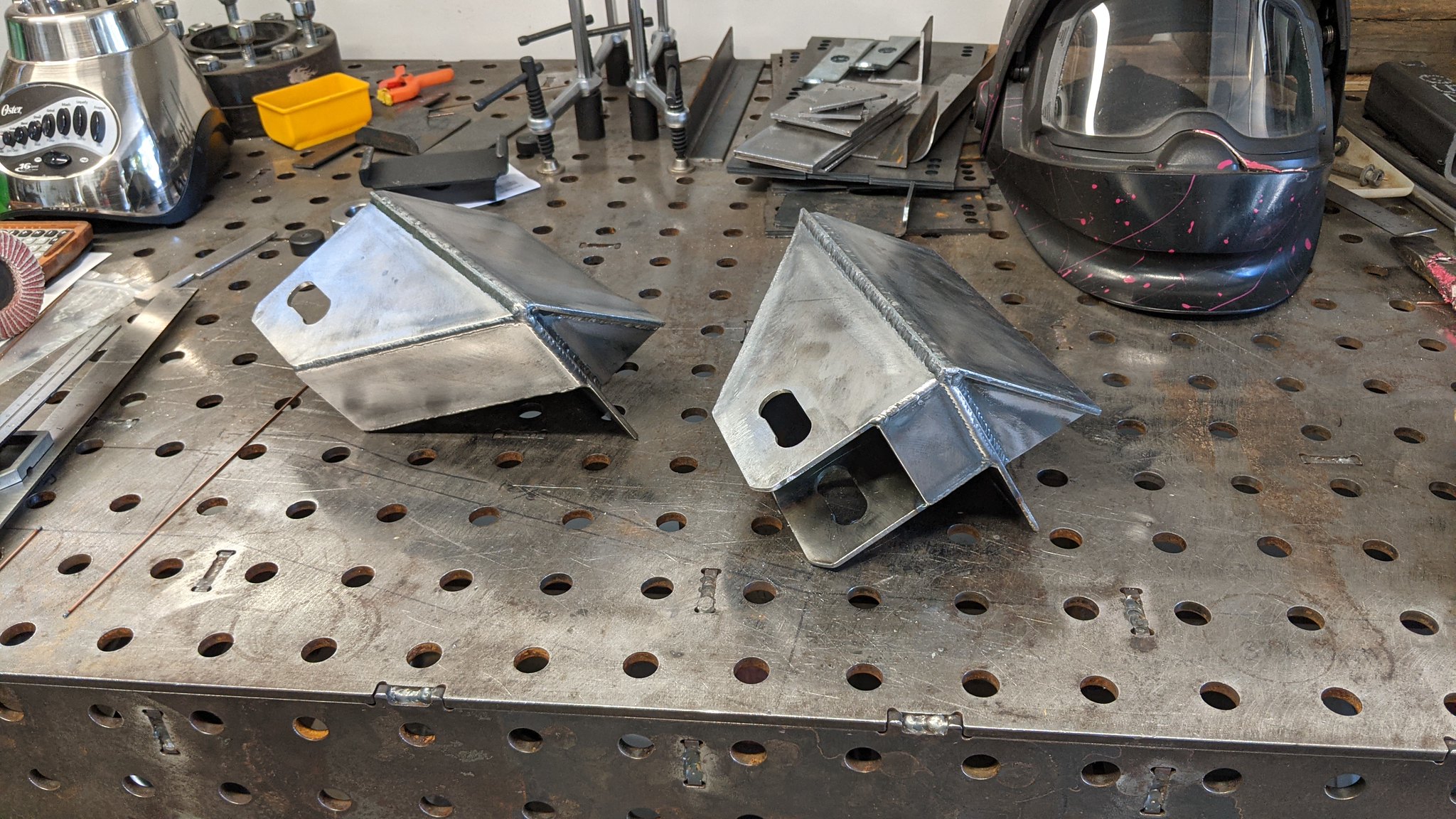

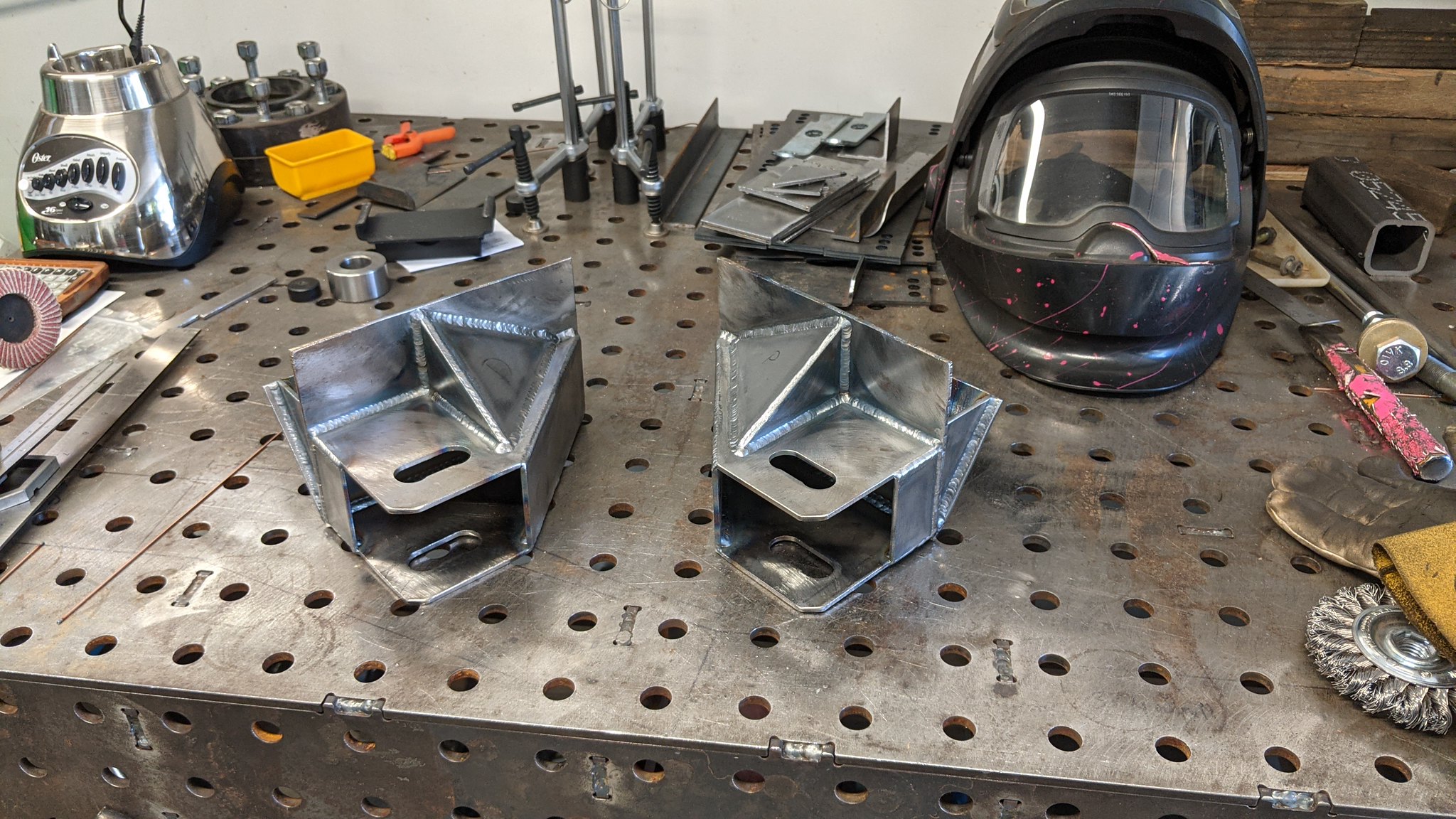

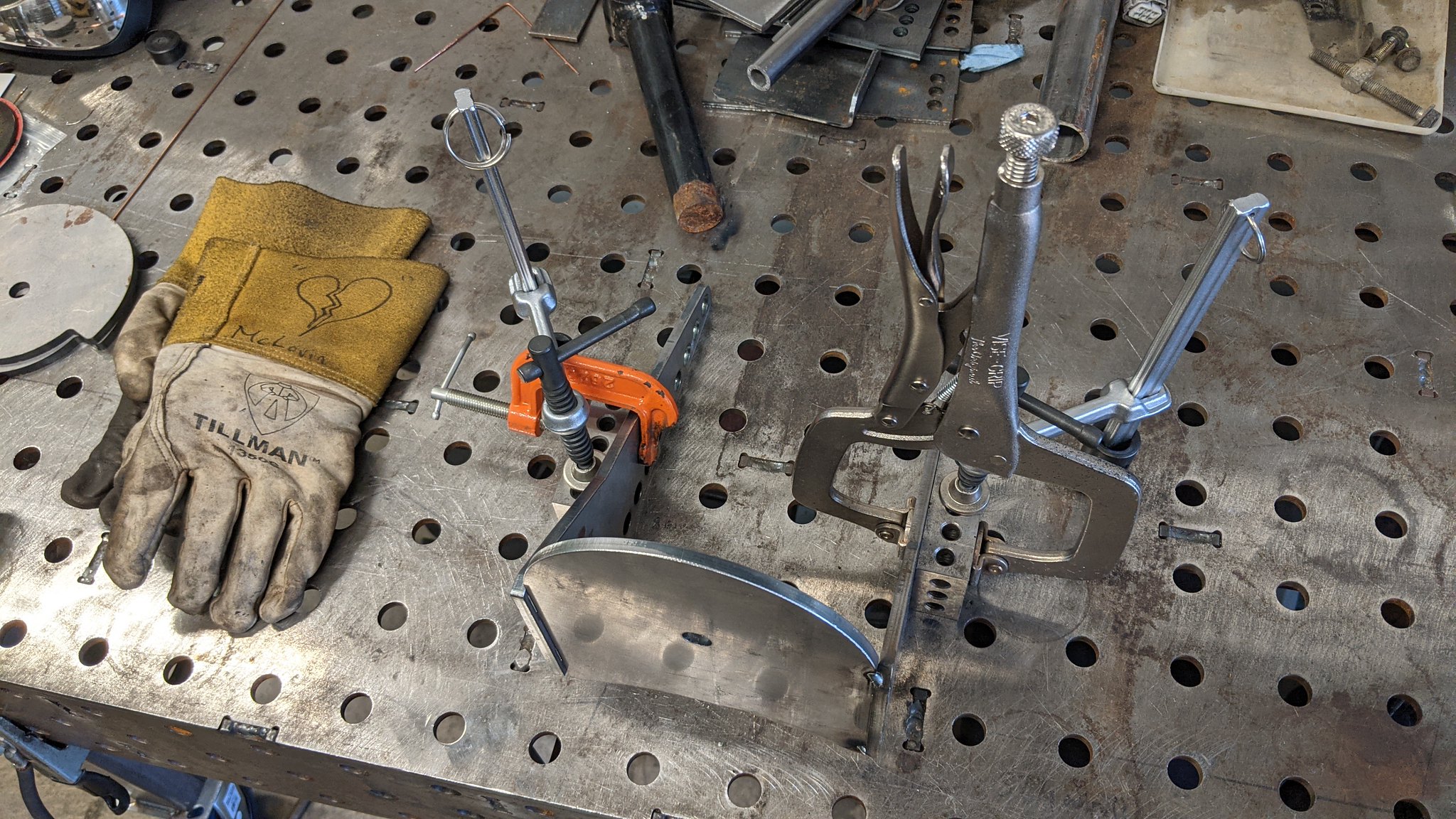

After the the test fit for the radius arms was complete, I made a couple adjustments for a little more strength and TIG welded everything together. I am not the worlds best TIG welder, so its certainly no weld porn.

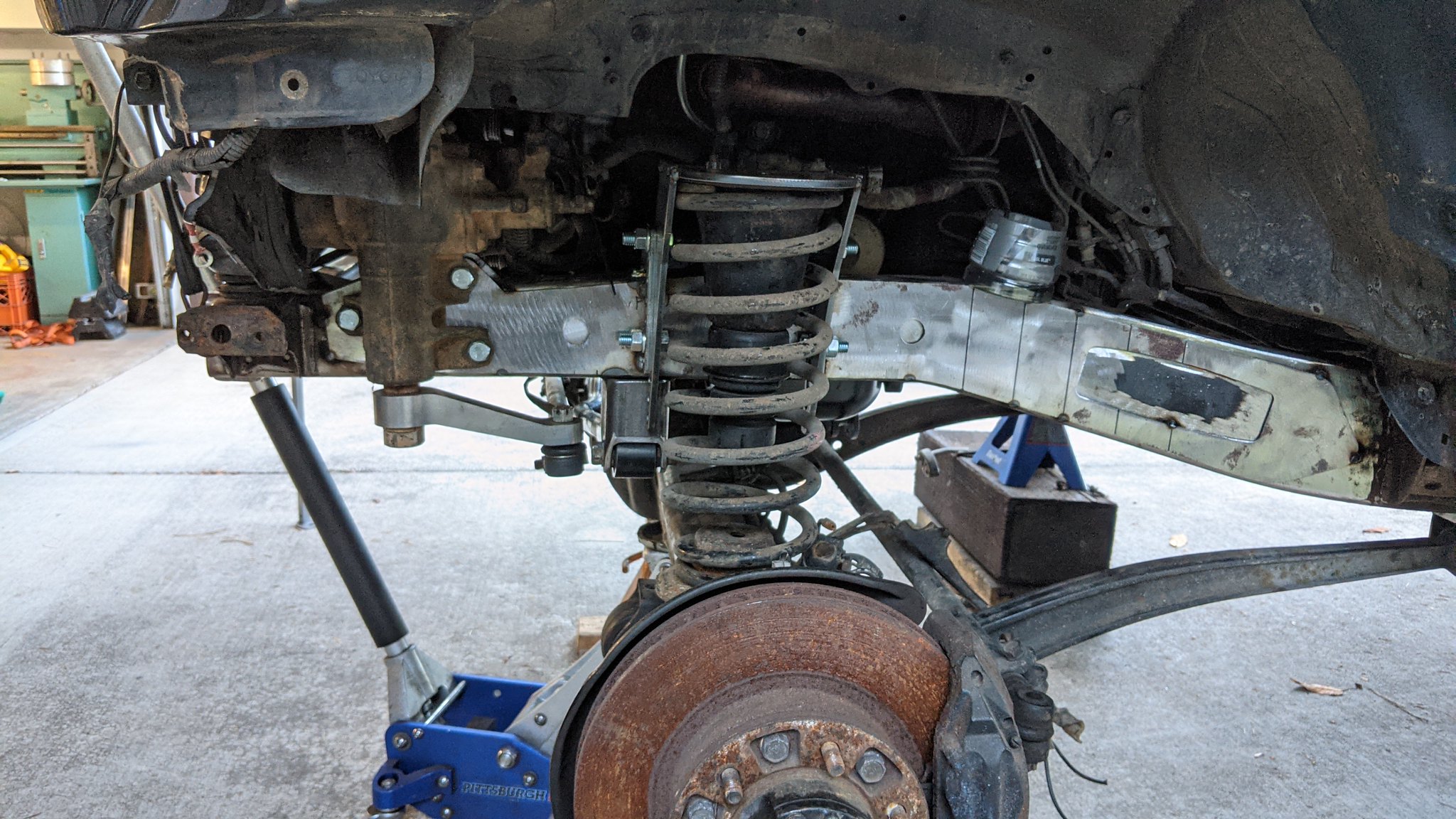

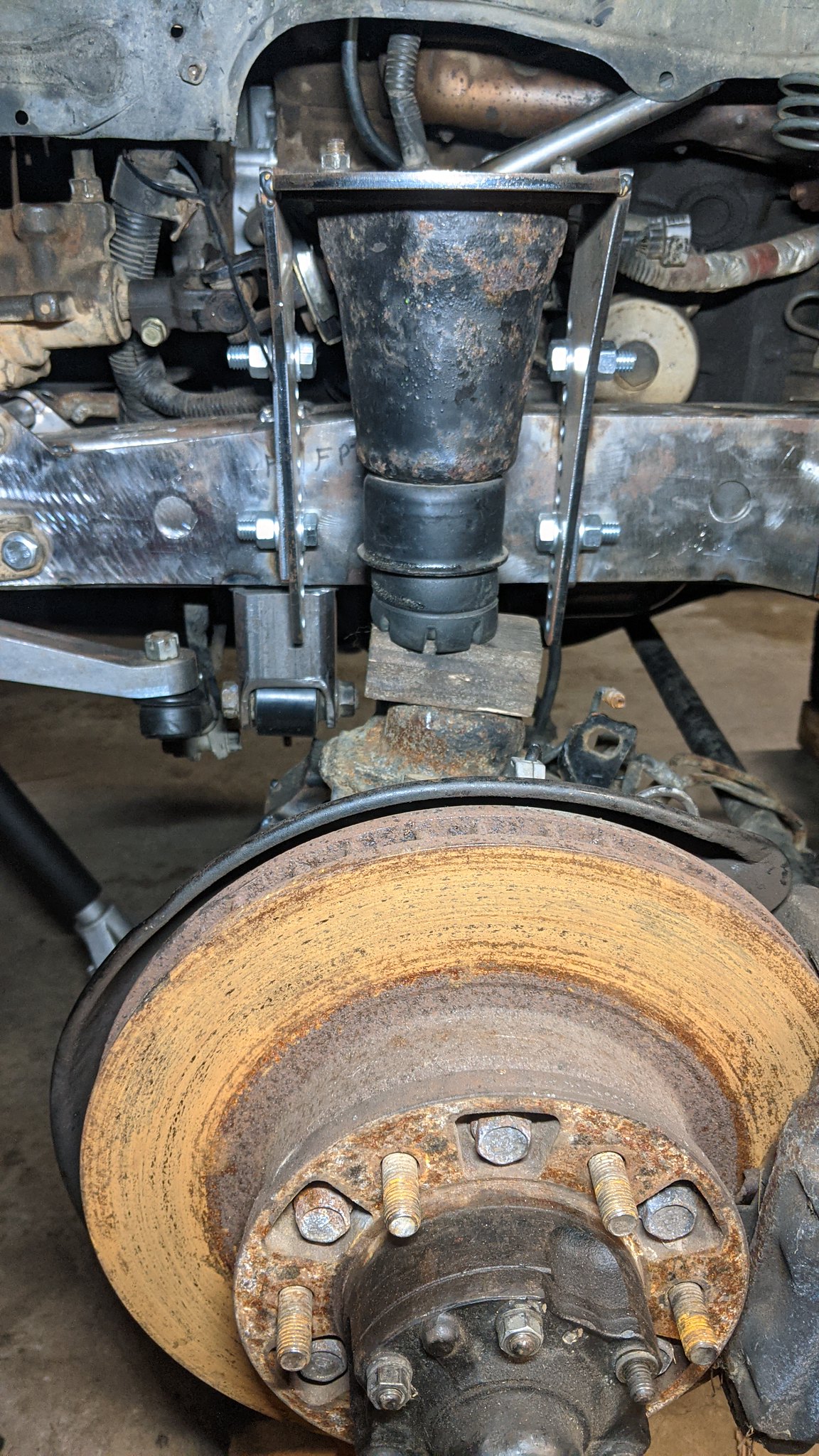

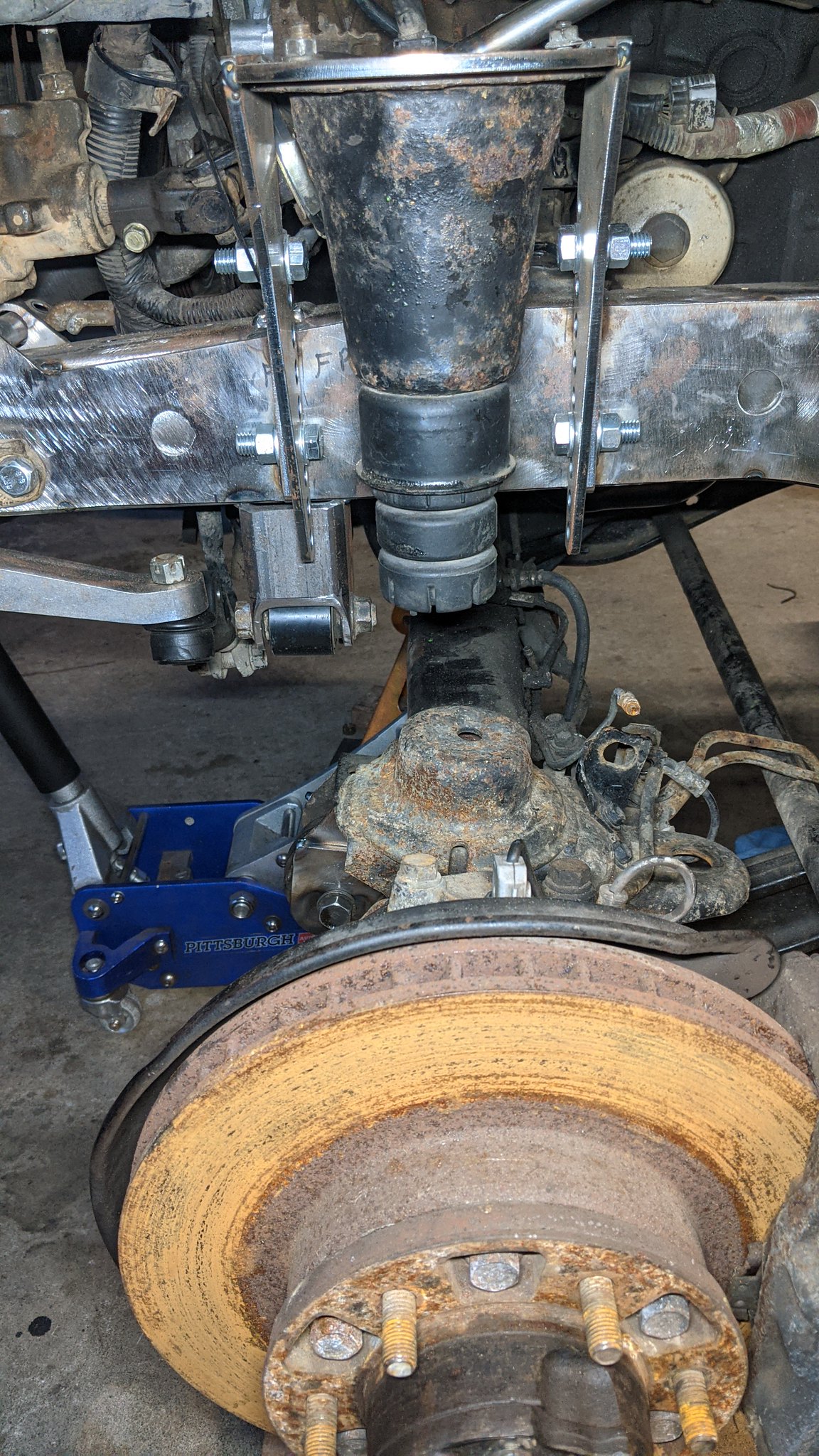

With them all welded up, I got them tacked in really firmly so I can eventually put some weight on the truck and see if everything landed where I wanted.

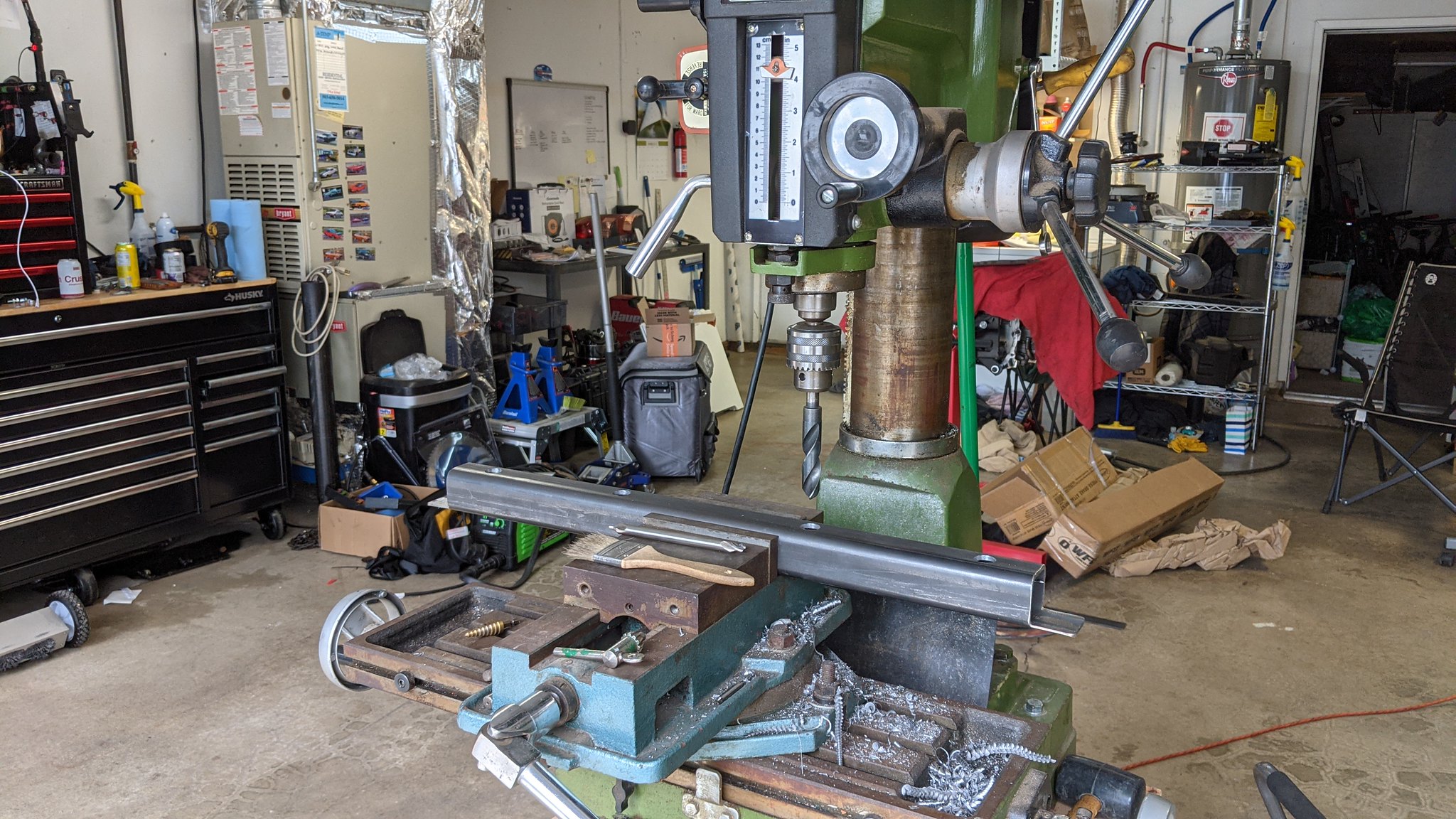

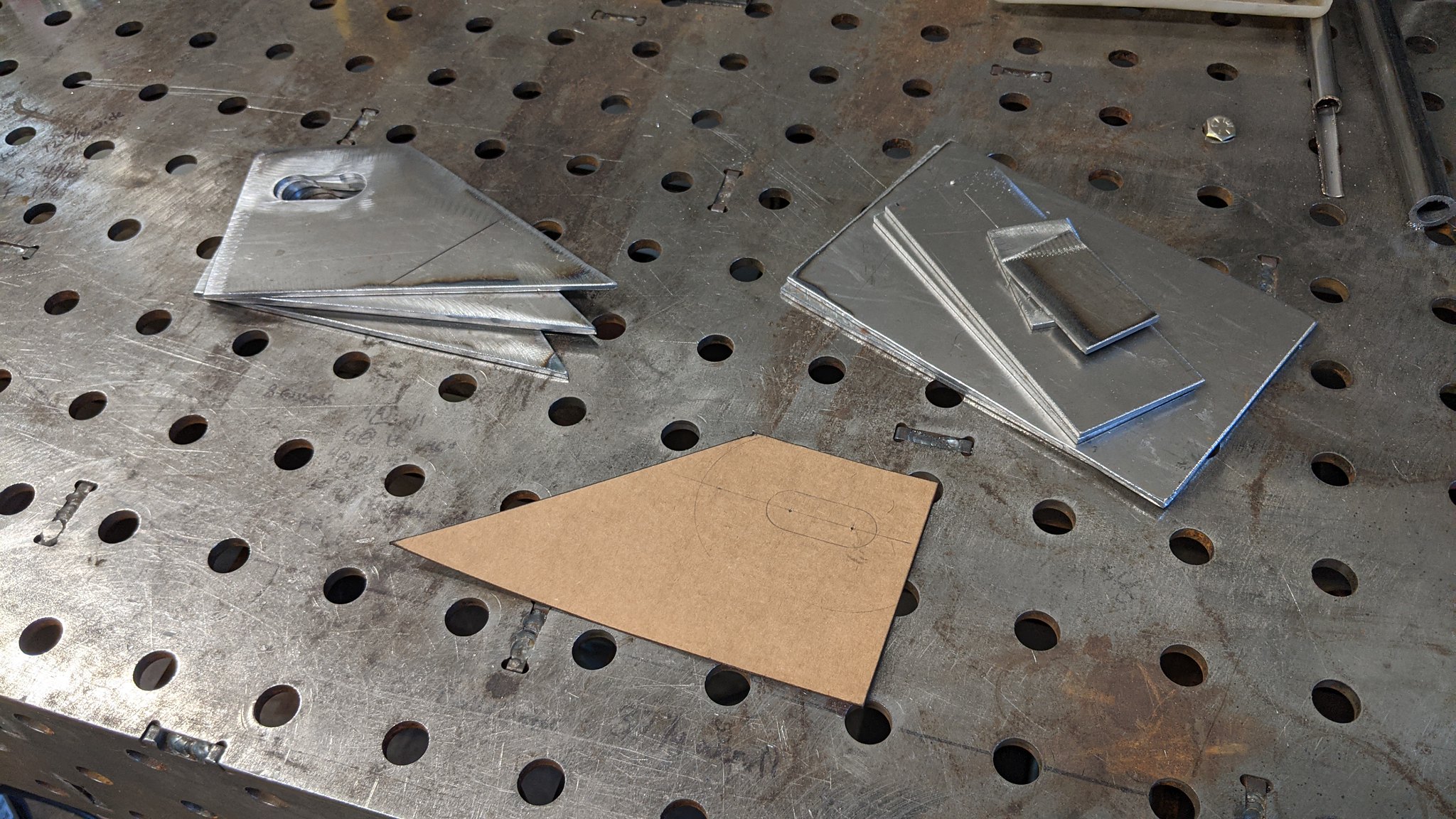

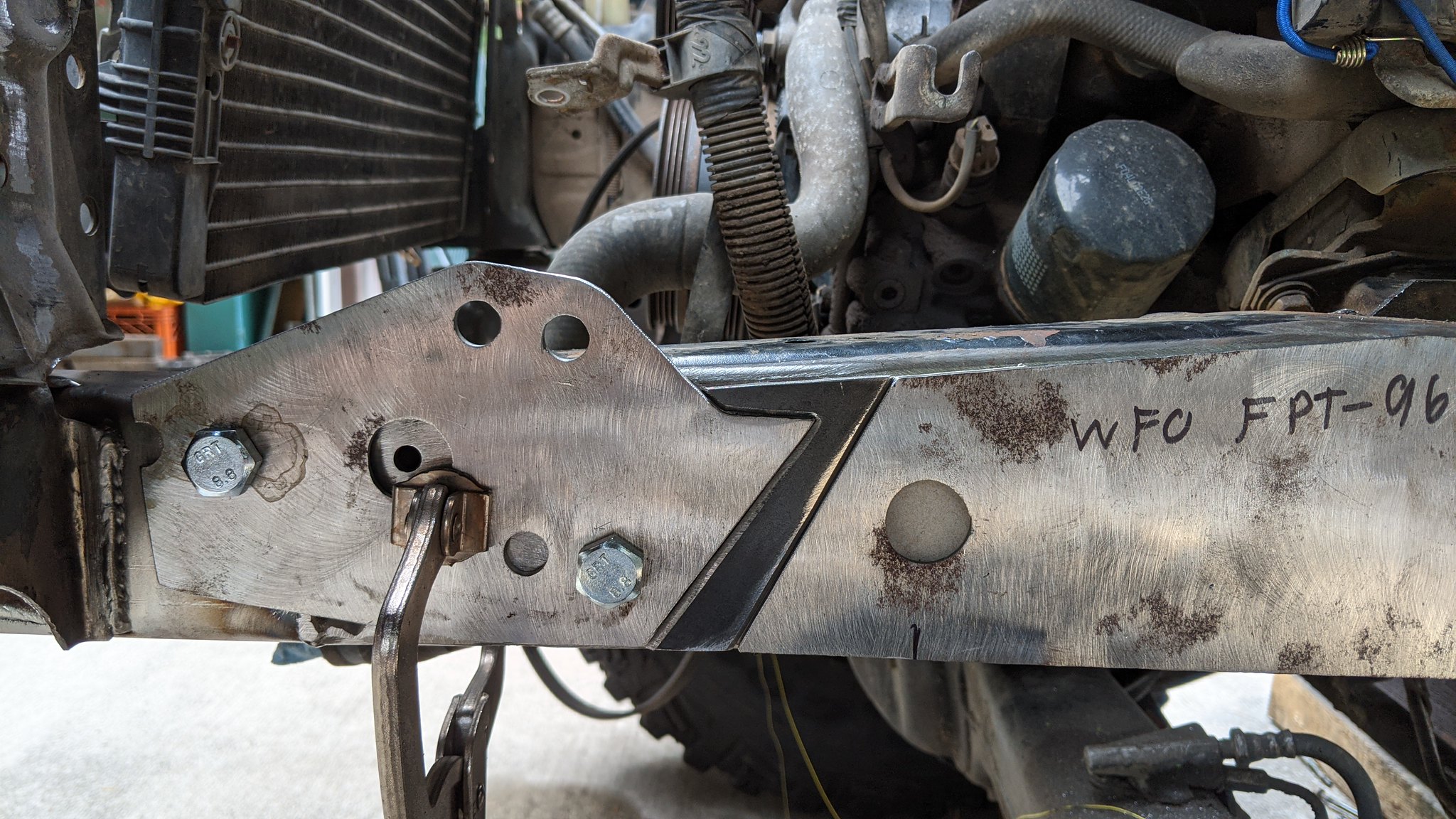

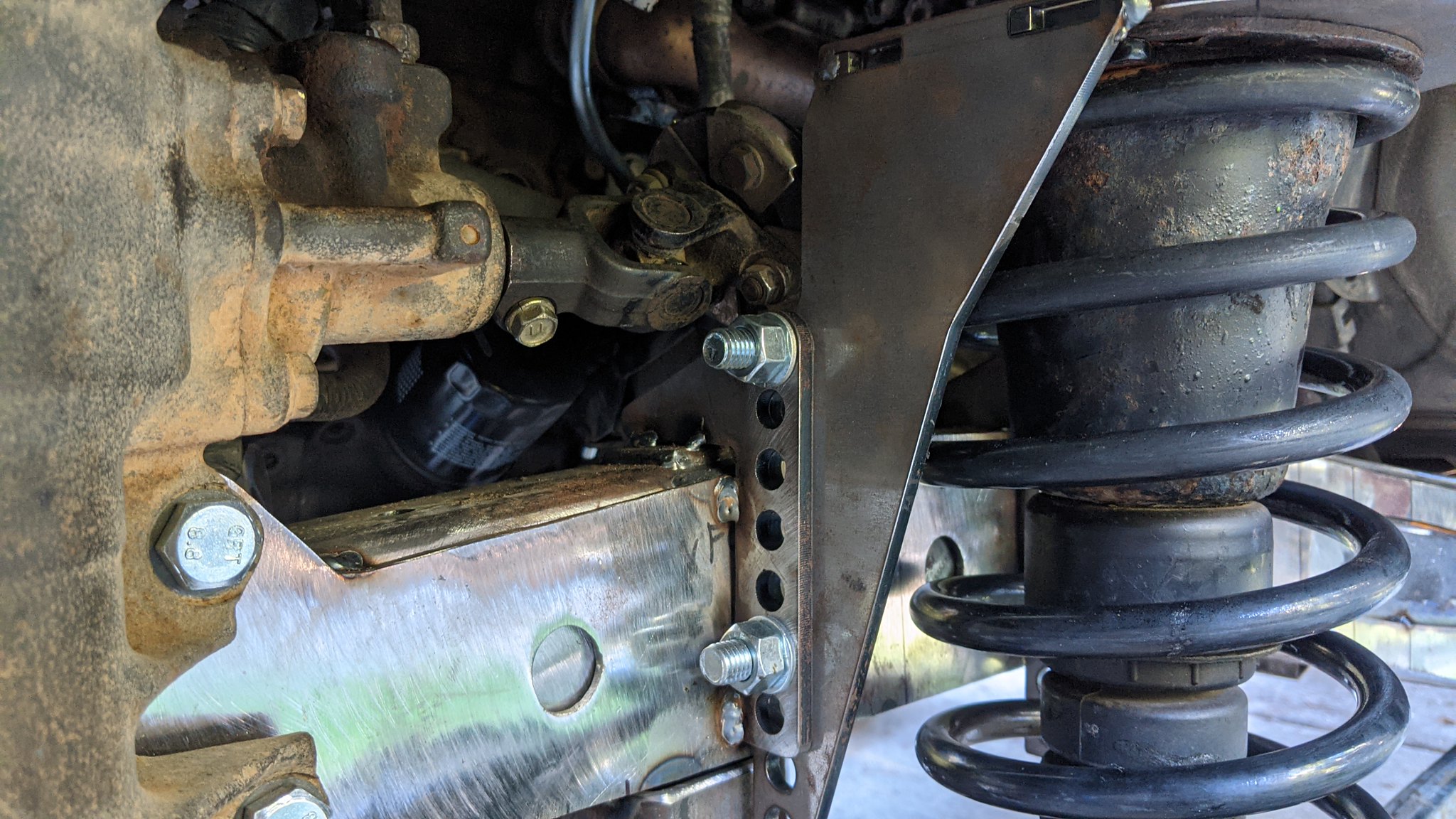

Next order of business was to get the steering box mounted. This proved to be a very time consuming process. Since I knew I planned on modifying the chassis plates to set the box in a better spot for my truck, I needed to set the steering before getting the plates tacked on and working on anything else such as coils mounts and panhard mount. The box got clamped to the bare frame(not pictured) and I and I marked the holes, then drilled the frame for the sleeves. Once the chassis was drilled, I cut the chassis plate and clamped everything on, so I could make a template for a filler piece.

With the holes drilled, the plate cut, and template made, I cut 2 filler pieces. I clamped both sides together before cutting anything, so I could duplicate the filler plate. Once the filler was made, I TIG welded everything together and ground it flush so you cant even tell it was cut. You'll see that in later photos.

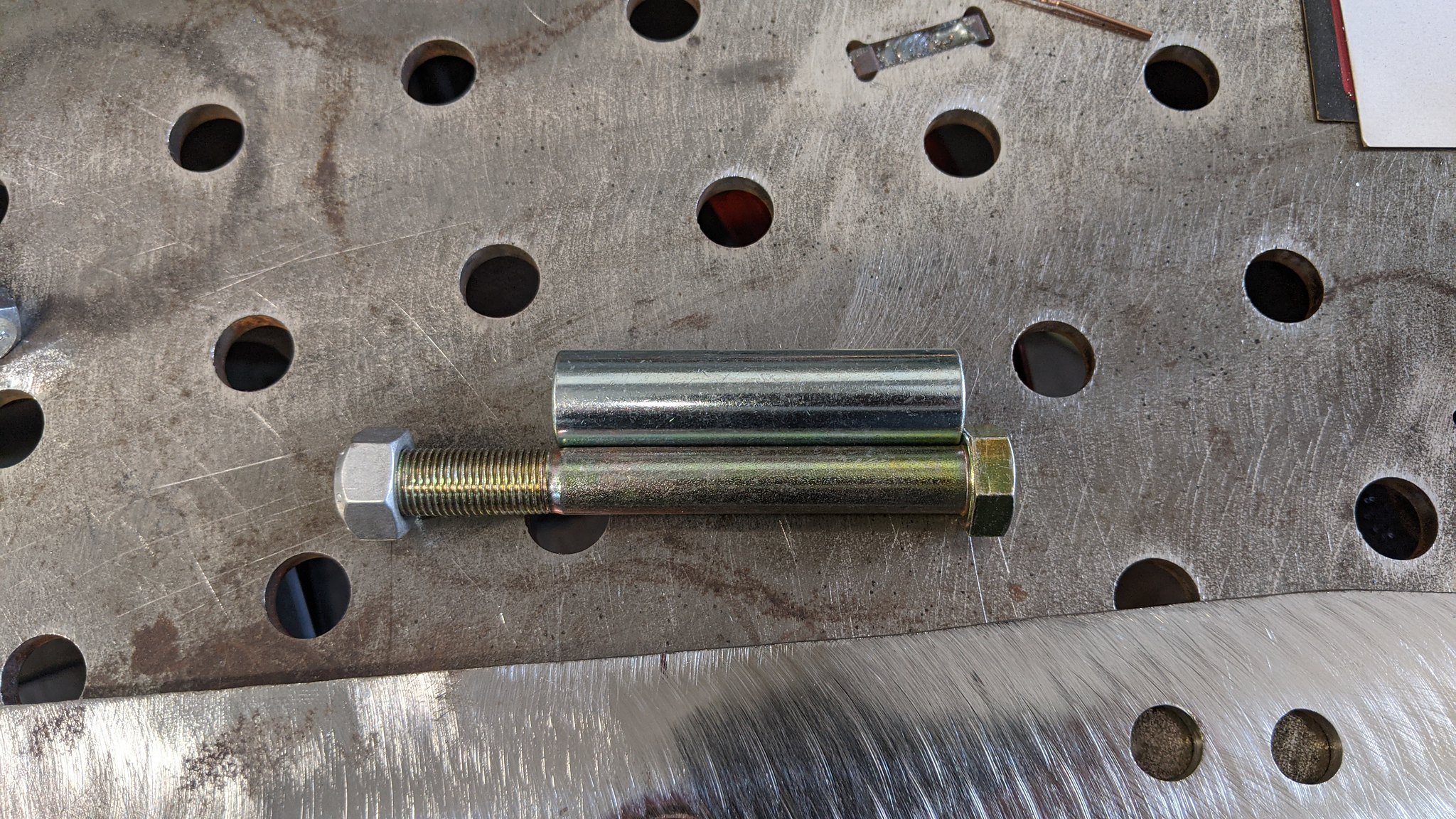

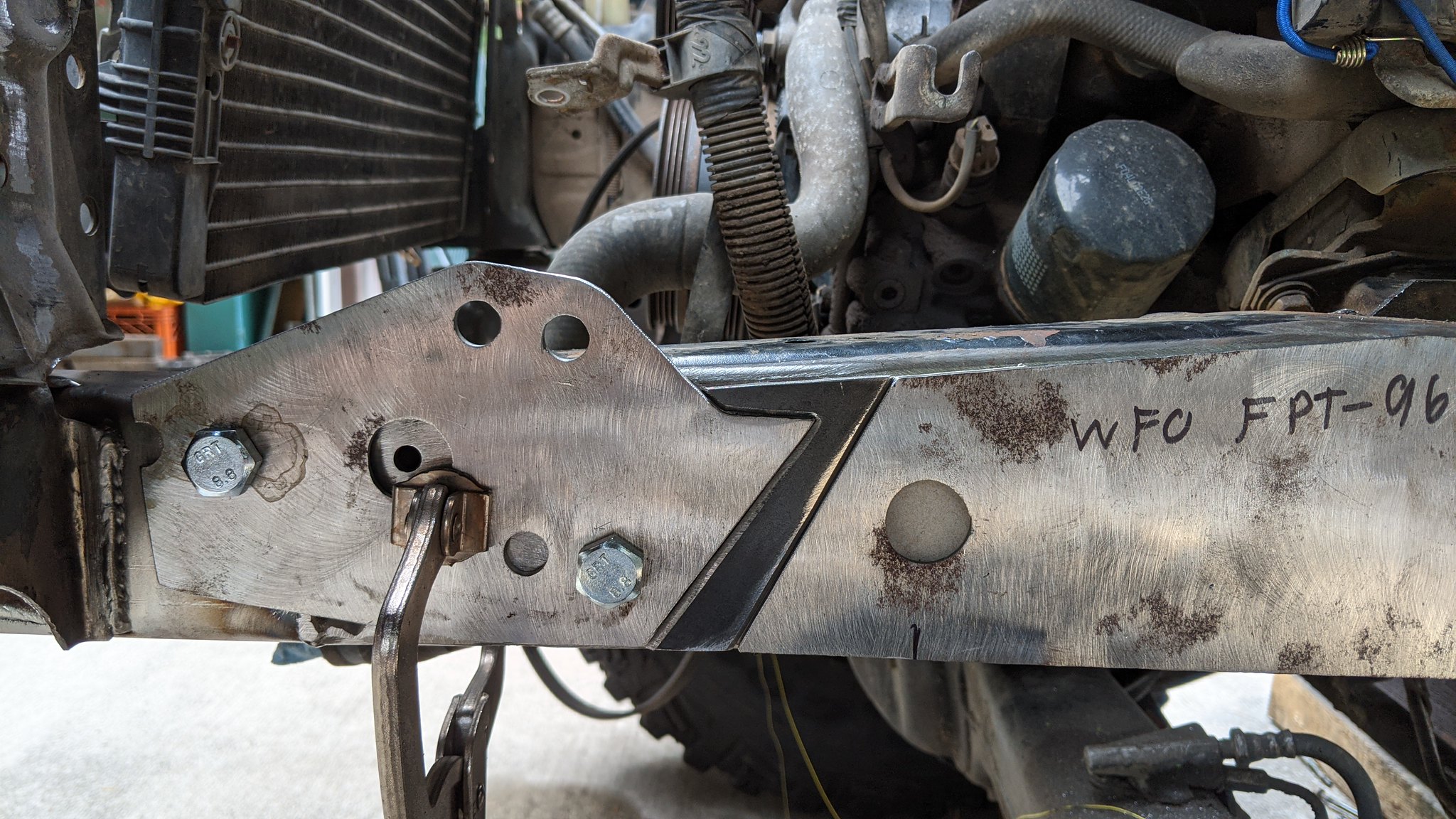

With the outside plate finished, It was time to move onto getting the sleeves for the steering box properly installed. This is where I have some criticisms of the kit I purchased. I got the kit from WFO because it looked closest to what I was doing. I knew there was a chance I would have to modify it, but that isn't where my gripe was. First of all, I would like to start by saying that I am probably unnecessarily OCD about some details. First of which, the hardware included is 1/2" fine thread grade 8 fasteners. Quality stuff, but I don't like mixing metric and standard hardware. It seems lazy and cheap in my opinion. Grant it, the easy solution is to run a 1/2" drill through the 3 holes on the steering box and move on with my life.... but that's not how I roll.

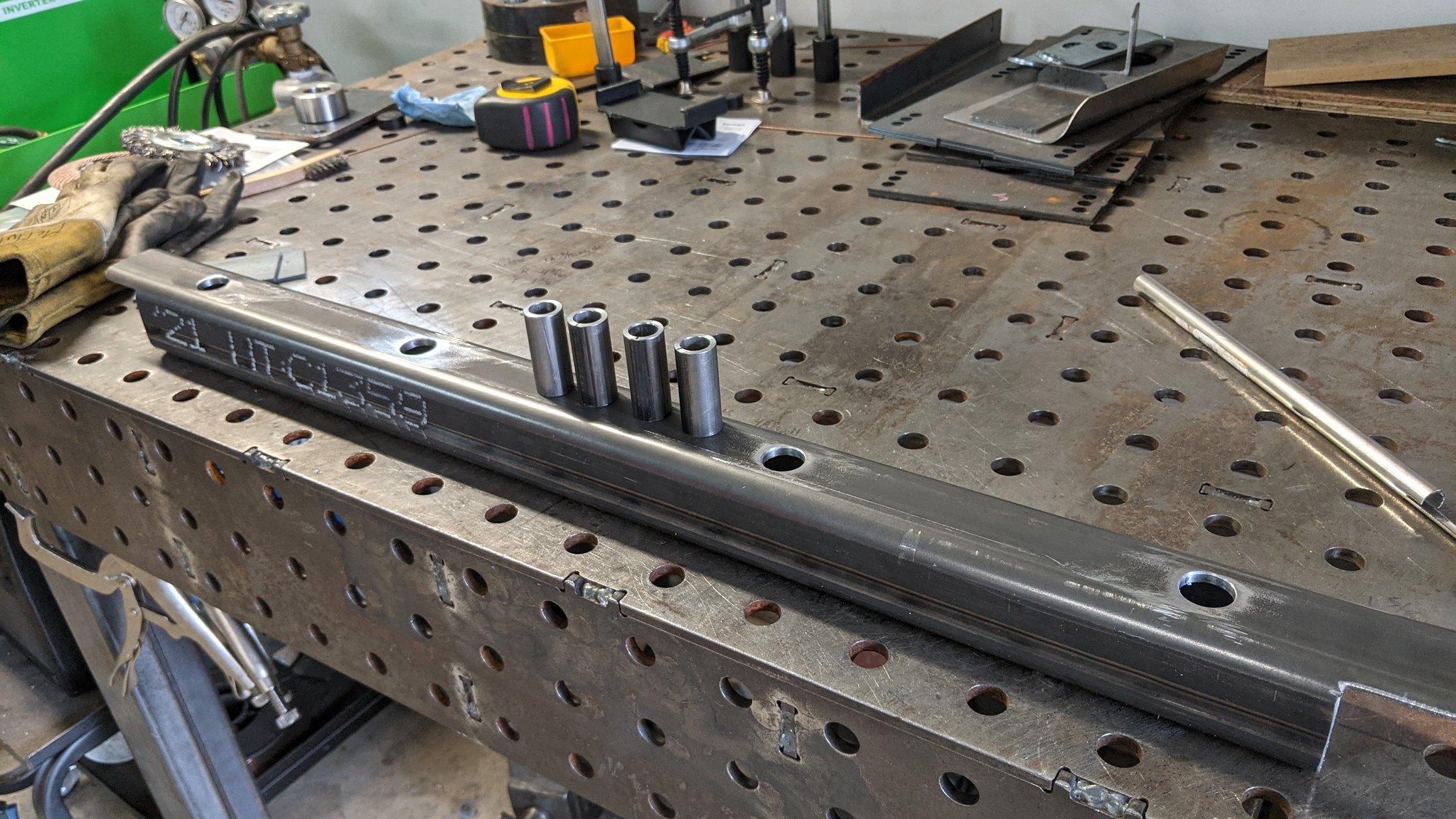

Second, and this one is truly just lame to me... is the zinc coated spacer sleeves. Anyone who welds/fabricates for a living knows that stuff needs to be removed for a good weld. More importantly, the fumes aren't good for you. A simple solution would be 3/4", .120 wall DOM or HREW cut to length. That's essentially what these sleeves are. Initially I was going to machine some proper sleeves, but said screw it and ground the zinc off in the places I needed to weld.

So this morning before getting started, I went to my local hardware store to grab some generic 12mm fasteners so I could fit everything up for now. Later I will source better fasteners after everything is blown apart for final paint and re assembly.

Rant off:

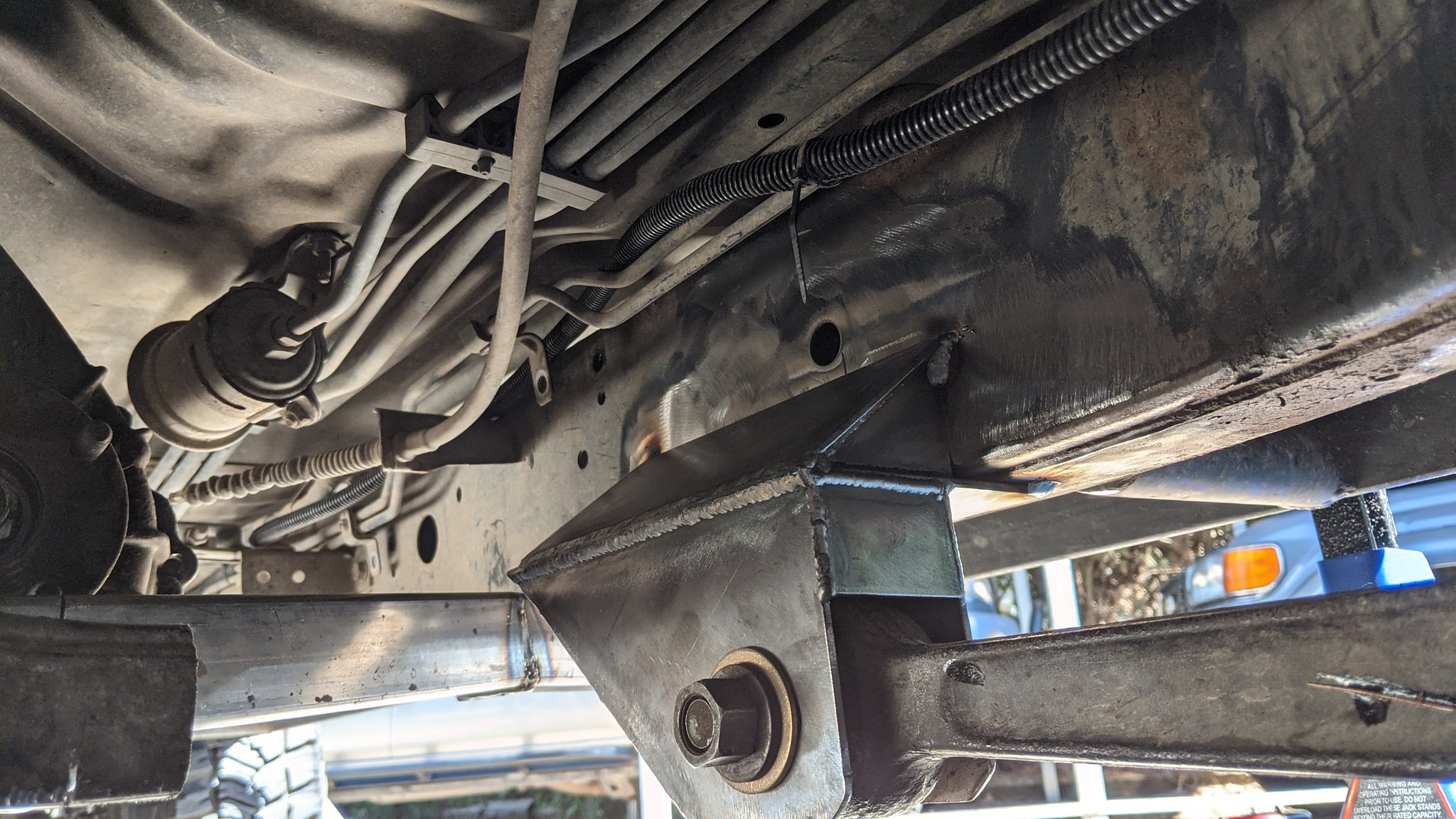

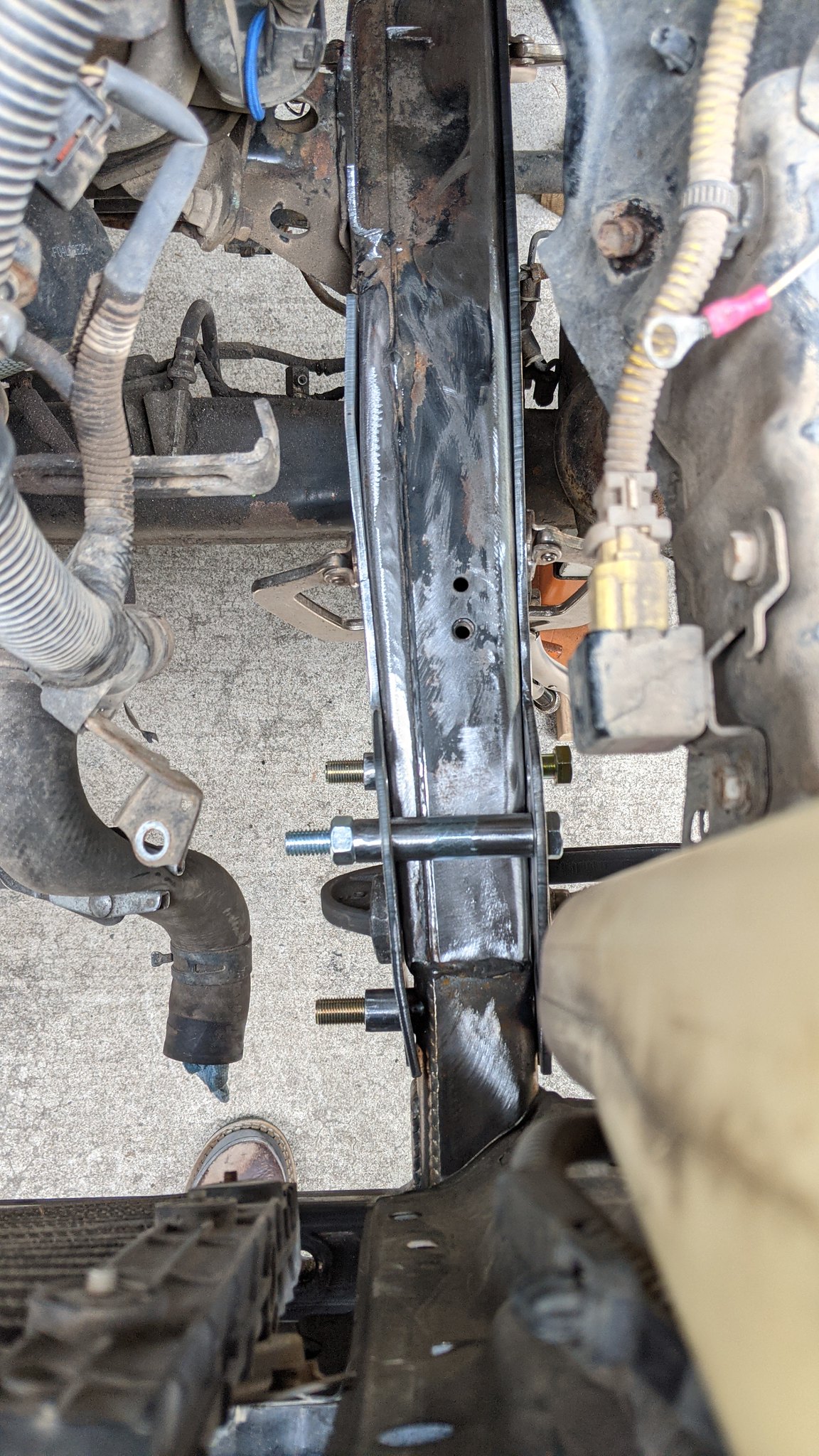

It was time to move onto getting the sleeves tacked on, square to the outside of the frame. It was more simple to clamp everything together using only the outside plate, and tighten the bolts to ensure the sleeves were sitting square on the chassis plates. After this, I took the chassis plate off, and welded the outside edge to the bare frame(I pre beveled everything to allow for weld), then ground it flush for the plates to sit nicely on the chassis.

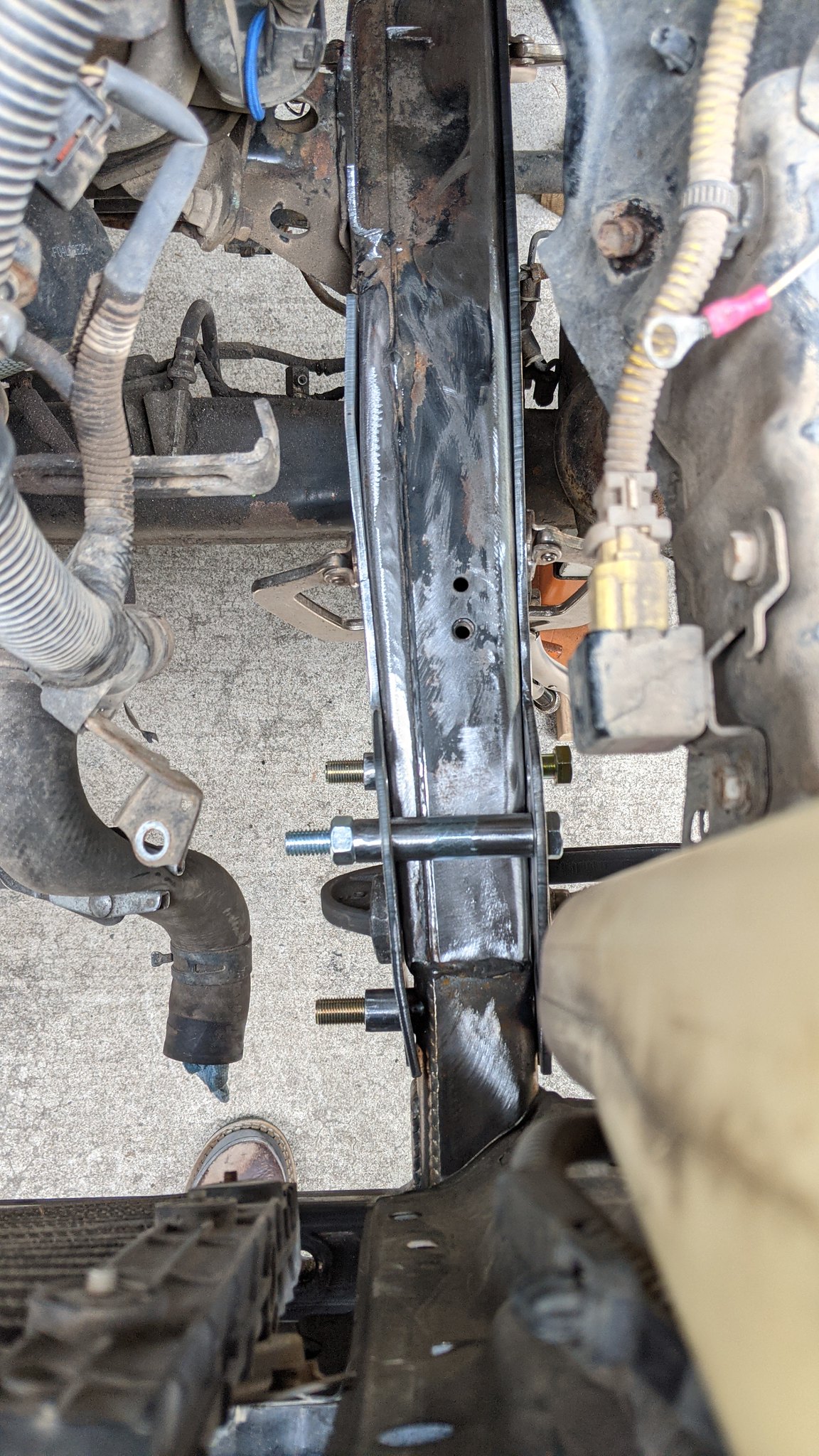

With the sleeves set, it was time to move onto the inside plate. First thing I noticed is there needed to be a bend closer to the engine mount. I don't like just clamping it out. That introduces stress to the frame and that's unnecessary.

So I put a little bend in it so it fits better. I also cut a little of the end, because it was interfering with the engine mount. It would have actually been worse if I didn't modify it already. So I suppose those are 2 more criticisms for the WFO kit.

With the extra bend, and the plate all welded up and ground flat, I had it fitting nicely. I did end up adding another small bend at the front of the chassis because of the small gap due to the replacement chunk of frame I made. So there is a small bend in the plate at the bottom of the photo and now that end sits nice and flat against the chassis.

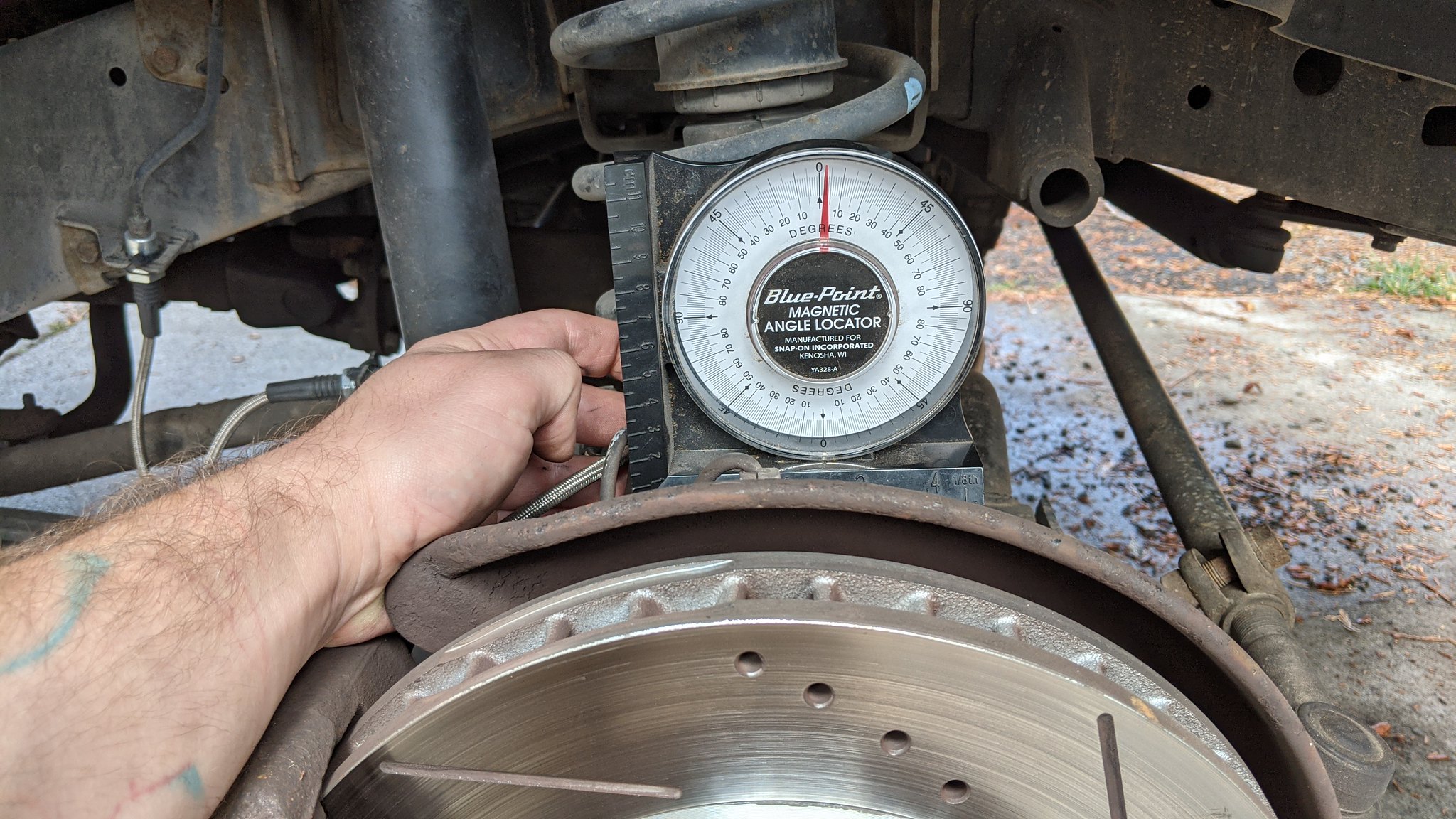

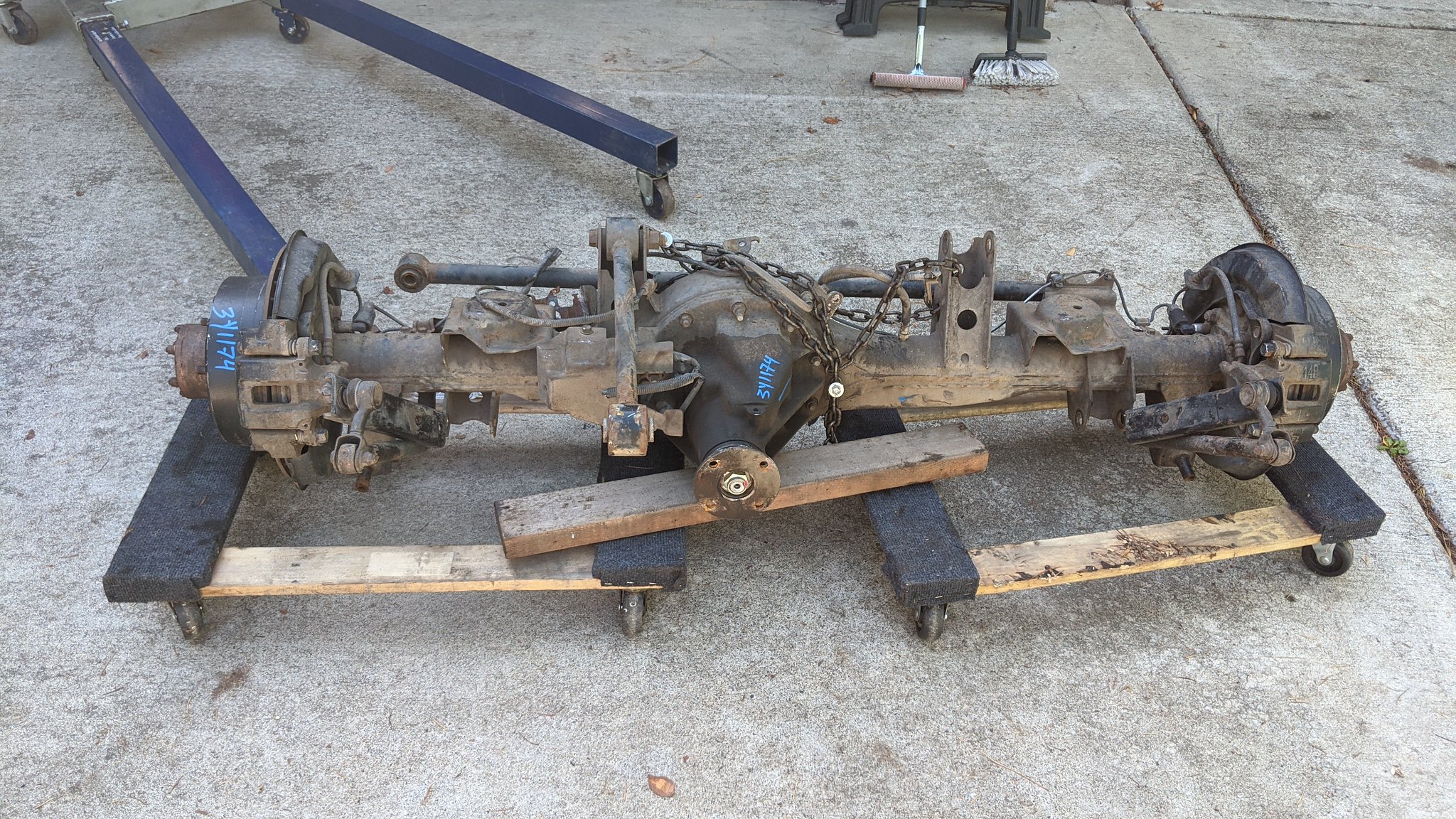

After putting together and taking things apart several times, I finally had the plates tacked on, and the steering box mounted temporarily. You can now see that he filler piece I made is un noticeable. I then re attached my string to see what the steering angles will look like, and I am reasonably happy. I think the truck will need to go up an inch or 2 , but it gives me a really close idea on where things will land. Then I tacked together a coil mount to start eye balling things. I cant really go any further now until I pull the axle out and swap the oil pan. The IFS pan is in the way of me making a panhard mount and getting a temp panhard bar in place to start fine tuning the side to side, as well as setting in the coil mounts. So that is a project for this next weekend.

www.expeditionportal.com

www.expeditionportal.com

www.expeditionportal.com

www.expeditionportal.com