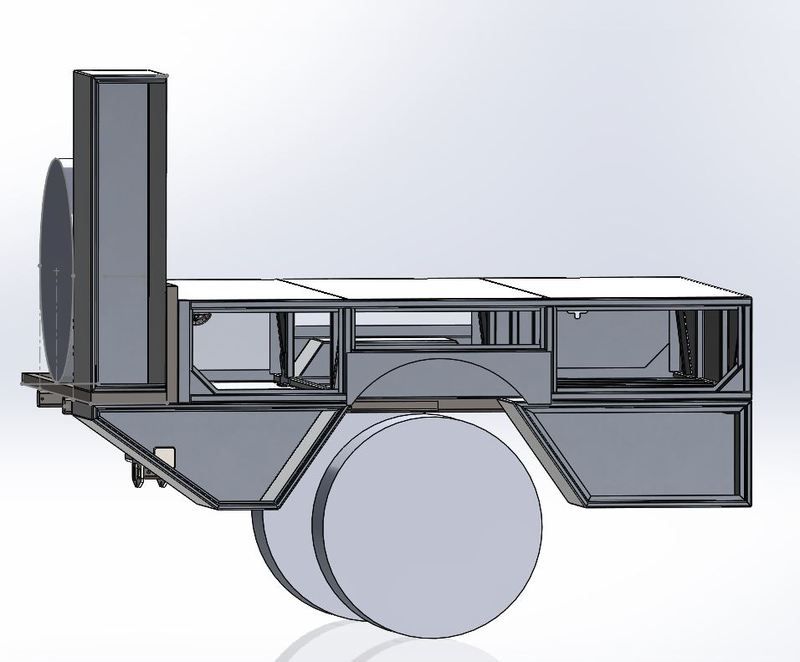

Issue I was having is that my rear kitchen, spare tire and motorcycle lift is pretty heavy and set substantially behind the rear axle. I had a suspension guru drive it and he felt that at times, the cantilever of that behind the axle weight was partially unloading the front axle and contributing to the bouncy ride in front. For several reason, I'm refabricating the rear kitchen. It will be smaller, closer to the rear axle and lighter, which should take some of the cantilever effect out. I'm also relocating my batteries and electrical bay to just in front of the rear axle. That coupled with 3" custom kings in the rear, 2.5" kings in front and hydraulic bump stops all around, will hopefully improve the driving manners. It's by no means bad right now, just trying to refine it.

First of all, AWESOME rig! I love your choice of V10, and keeping CG low with a basement.

I agree with bajajoaquin - your truck is much closer to the front GAWR than the rear, I wouldn't recommend further relying on the front to cantilever the rear. You also have to consider the polar moment of inertia when putting mass at extreme ends of the vehicle. You may achieve a better WEIGHT distribution, but very poor MASS distribution!

Is your front suspension still stock? Can you be more specific about the rough ride - is it bottoming out, topping out, or over spring and under-damped?

Knowing the exact issue would allow your suspension tech to better fine tune spring rate, damping, and travel for its current weight.