jscherb

Expedition Leader

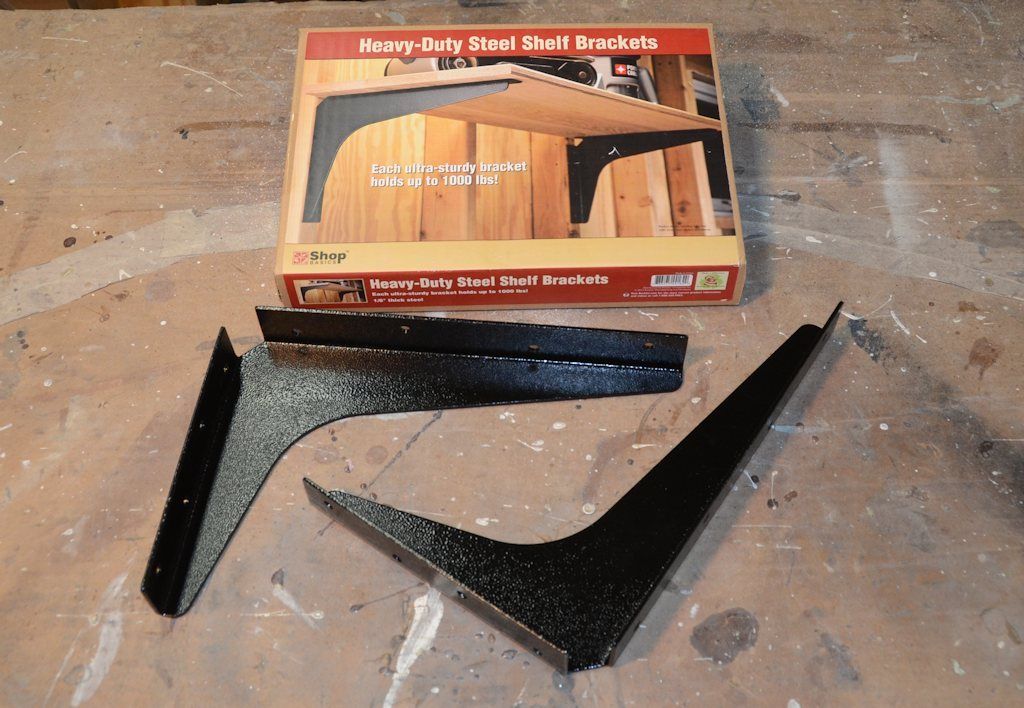

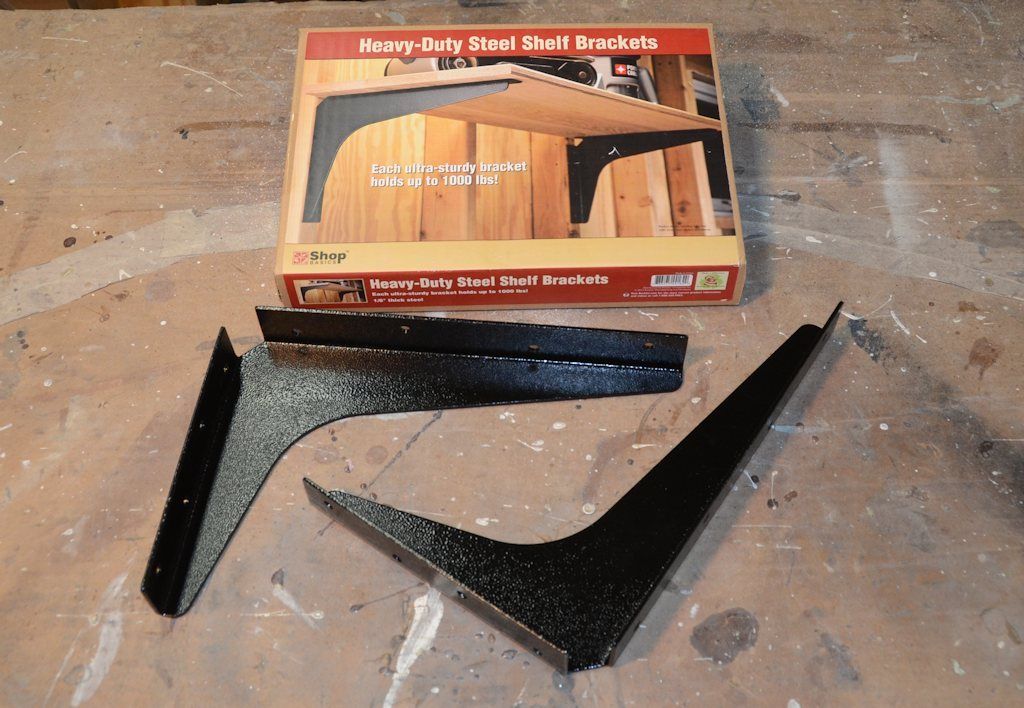

I was in a Rockler Woodworking and Hardware store yesterday and spotted a set of heavy-duty shelf brackets. They're 8x12, made from 1/8" steel plate, and nicely powder coated.

I couldn't resist buying a set to try mounting and ammo can to the tailgate hinges. They're a perfect size, all it will take is drilling an extra hole or two in them to match up to the holes in the hinges.

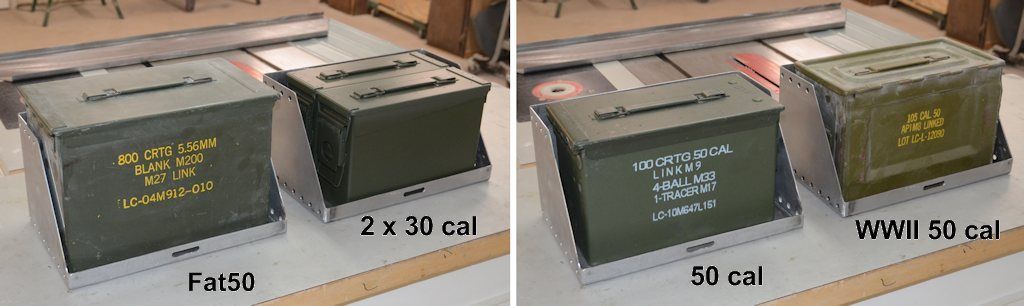

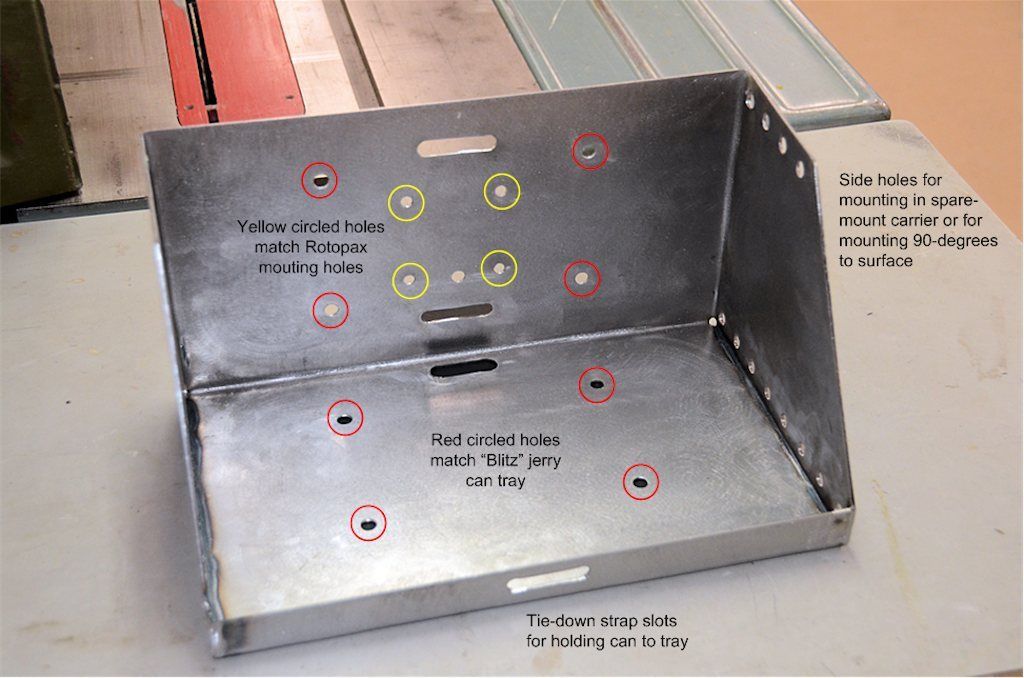

They would work for mounting an ammo can, they're shown here with the 30 cal ammo can tray I made last week:

Or a jerry can. The jerry can tray in the photos below is available, so there's no fabrication involved, just drilling a few holes in the bracket and the tray.

When I get a few free minutes I'll do some test installs on my LJ and the JK to see how these brackets work out.

I couldn't resist buying a set to try mounting and ammo can to the tailgate hinges. They're a perfect size, all it will take is drilling an extra hole or two in them to match up to the holes in the hinges.

They would work for mounting an ammo can, they're shown here with the 30 cal ammo can tray I made last week:

Or a jerry can. The jerry can tray in the photos below is available, so there's no fabrication involved, just drilling a few holes in the bracket and the tray.

When I get a few free minutes I'll do some test installs on my LJ and the JK to see how these brackets work out.