Stoffregen Motorsports

Explorer

It's been a busy winter here in the Gold Country. Our winter storms brought so much rain and wind that I have been chasing my tail trying to play catch up. We actually had a tree fall on or house on New Year's Eve, which partially tore the chimney off the roof. Big oak, almost 3 feet in diameter, but even with all that weather and paying work besides, I snuck in some personal time for the Cherokee.

One of my pet peeves is body rot. Luckily for me, the Cherokee had rot only in sections of the body that would not require disturbing any of the original orange paint. Well, mostly. The majority of the rot was in the lower rear fender flares, with a couple spots of rust in the passenger floor sections near the rear fender wells. Nobody sells replacement steel fender flares for the full size Cherokees, and if the wrecking yard had them, which they did not, they would have charged $500 per flare. I can make them for the price of steel, plus a ton of hours. I did buy some lower rear quarter repair panels for a Wagoneer, from BJs Off Road, and they needed to be modified to fit. That was easy enough. In all, I cut out and replaced 17 different sections of body, and it took nearly three weeks to do.

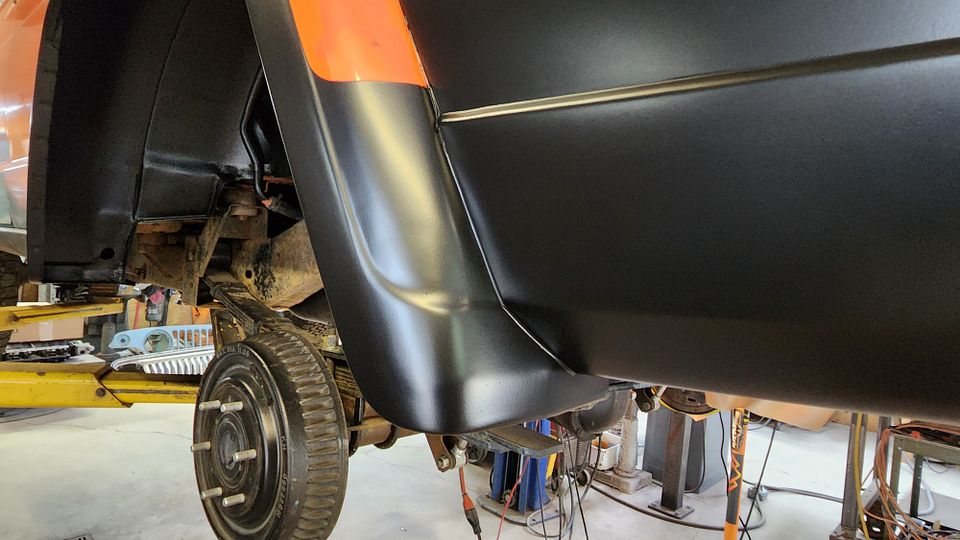

Here is the front section of the left rear fender/rear floor patch.

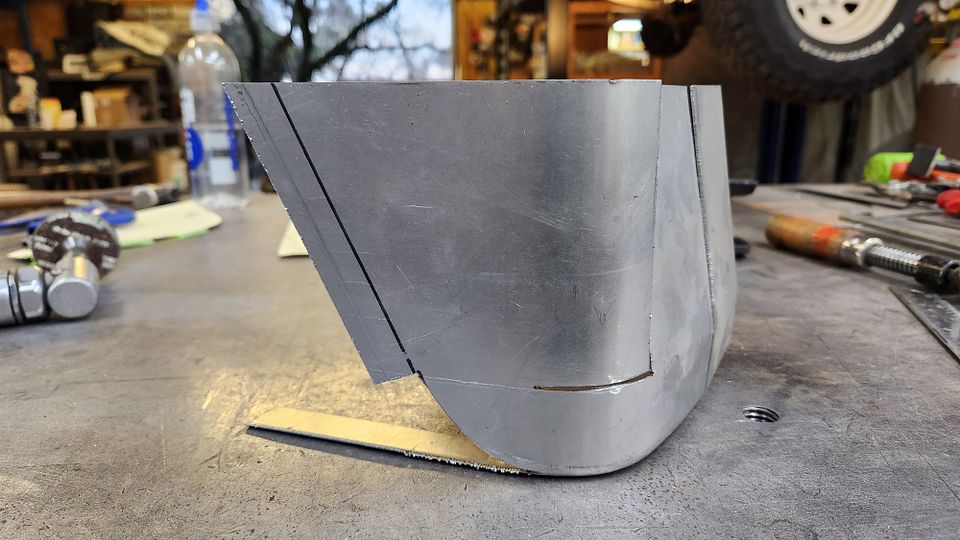

And then on to more complex shapes, the rear lower section of the flare. It has an inner and outer piece.

One of my pet peeves is body rot. Luckily for me, the Cherokee had rot only in sections of the body that would not require disturbing any of the original orange paint. Well, mostly. The majority of the rot was in the lower rear fender flares, with a couple spots of rust in the passenger floor sections near the rear fender wells. Nobody sells replacement steel fender flares for the full size Cherokees, and if the wrecking yard had them, which they did not, they would have charged $500 per flare. I can make them for the price of steel, plus a ton of hours. I did buy some lower rear quarter repair panels for a Wagoneer, from BJs Off Road, and they needed to be modified to fit. That was easy enough. In all, I cut out and replaced 17 different sections of body, and it took nearly three weeks to do.

Here is the front section of the left rear fender/rear floor patch.

And then on to more complex shapes, the rear lower section of the flare. It has an inner and outer piece.