Cruisn

Adventurer

Was an excellent week for new parts arriving!!

Started with my maps showing up: canning stock route, anne beadell highway and wa's top 50 treks.

Then my led light up switches arrived:

Iron man recovery kit:

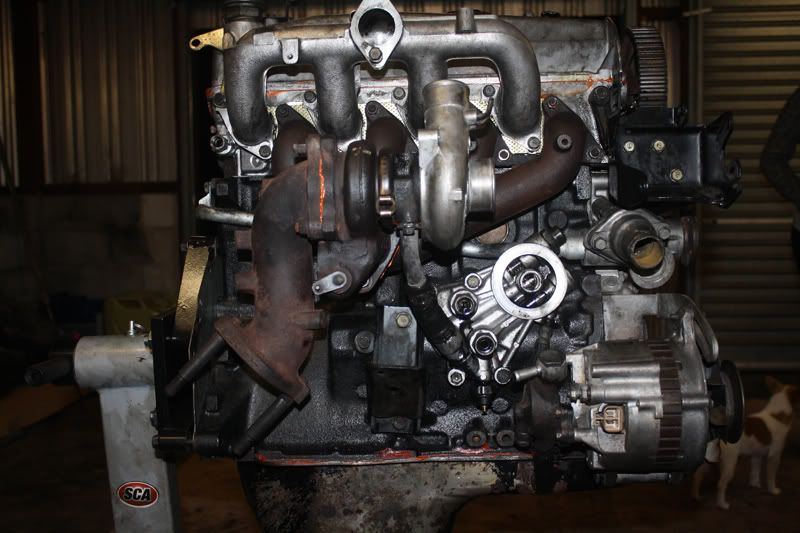

Repair manual, pdf version. everythign I need for the diesel at least.

The best for last, My safari snorkel, been waiting a few weeks for this to arrive. cant wait to install it.

Its legit: no fake stuff here

Started with my maps showing up: canning stock route, anne beadell highway and wa's top 50 treks.

Then my led light up switches arrived:

Iron man recovery kit:

Repair manual, pdf version. everythign I need for the diesel at least.

The best for last, My safari snorkel, been waiting a few weeks for this to arrive. cant wait to install it.

Its legit: no fake stuff here