I just saw someone else mention the F-350/3500 DRW option in another thread, too, and I think it's really viable!

It adds an extra 1,000-1,500 lbs to the payload capacity, and I believe is a bit narrower than the F-550/5500?

I didn't realize they don't run 19" tires. Another win, IMO. I suppose you could always single them down later if you wanted to.

That's a great suggestion! Thanks!

I think the best payload of a current Ford 4x4 DRW CCLB F-350 with the gas 7.3L “Godzilla” engine is about 6,600 pounds. It has a fully boxed frame. Please note that 2017+ F-350s can have much better payloads than older one ton pickup trucks.

The current DRW 17” rims use tires that can be aired down, but they might rub depending on amount of airing down and the space between the rims when bolted to the rear axle. ... You might consider ordering the F-350 you want, then having a couple of rims made to replace the outside rims of the DRW. This would increase stresses on the rear axle, but so would going to large super-singles. The truck would be mostly stock, but capable of being aired way down.

The 450 and 550 truck rims shouldn’t be aired down. They hold the tires on differently than the 17” rims. The tires can catastrophically fail after being aired down and up.

The turning radius of the 450/550 chassis cab trucks is quite useful, as is the greater payloads compared to the F-350, but the F-350 tires with 17” rims can be aired down, and there are many more to choose from.

Keep in mind that beaches vary, but, as a general rule, the lighter the vehicle the better.

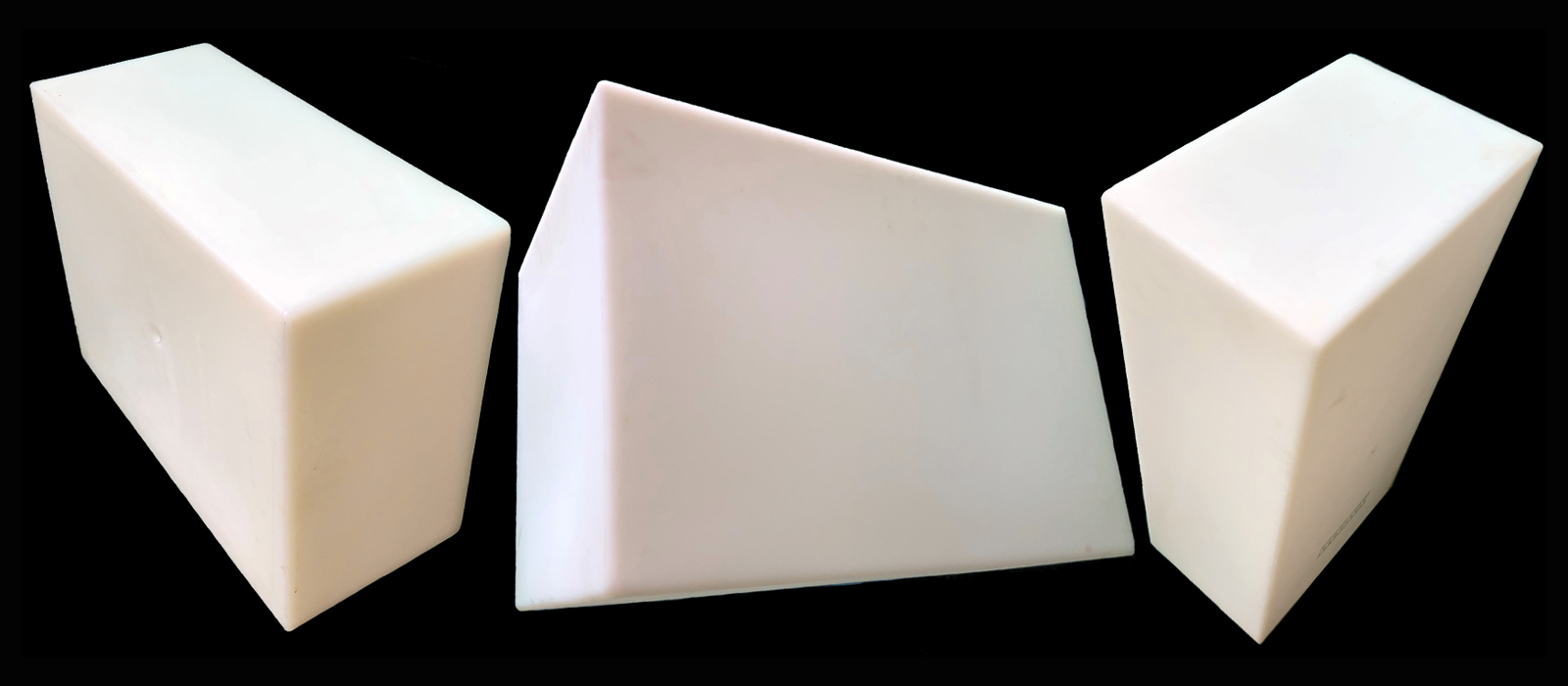

One of the cheaper ways to build your camper-truck, IF you can keep the weight down enough to be able to use a 2017+ F-350 4x4 DRW CCLB 7.3L gas engine pickup truck, would be to order such a truck, remove the pickup bed, install a Duramag (or Bowen) flatbed, then build your camper on it, especially if you use thin plywood, wood, and foam. ... The 2017+ F-350 pickup’s fully-boxed frame would help minimize camper flexing.

Even cheaper would be to use the above pickup truck with the original bed. Build a basement for tanks and design an 8’ wide habitat floor that is just above the bed-rails.

Keep the costs down enough and build 2 “pirate” campers, one for summer and one for winter. 😎

With the right Ronco Plastic 50 gallon water tanks and grey tanks, I think you could carry 100 gallons of freshwater and have capacity for 100 gallons of greywater, although you probably don’t want to carry both at the same time, in the basement located in the bed of the pickup truck bed.

Marine tanks are suitable for all marine plumbing, waste holding, and water supply needs. The tanks are rotationally molded of a seamless one piece, non-corrosive linear polyethylene and meet FDA regulations. Three female NPT (national pipe thread) fittings are provided free of charge...

ronco-plastics.com

I know that you have mentioned a disinterest in a slide-in camper a few times, BUT, I’ll suggest you ponder building your camper to slide in to a pickup truck bed AND I’ll suggest that you ponder building your camper on a pickup-mounted flatbed (or near-flatbed such as the Bowen).

As a note, the water tanks, placed in the basement of slide-in camper would sit a bit lower than on the floor of a flatbed on the same pickup-truck frame (because the flatbed sits above the tires).

The 2017+ F-350 uses different springs than the 2017+ F-350 chassis cab, and would likely give you a better ride.

So, can you keep the weight down enough to use a DRW pickup truck? 😀

Maybe you need to build a camper AND a HTT? (Hood Top Tent) 😎