Metcalf

Expedition Leader

I'm still waiting for my tie-rod reamer. It is suppose to ship today....

Yesterday I had an hour or two in the work shop.....

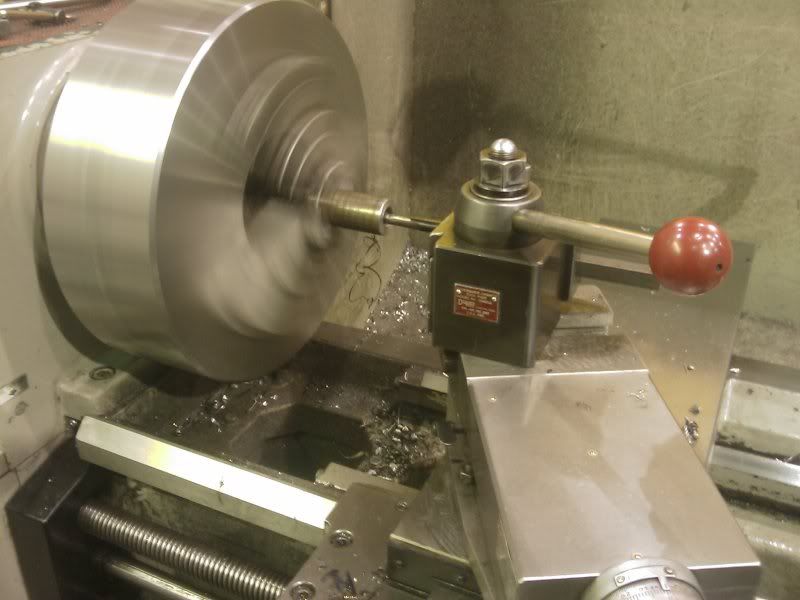

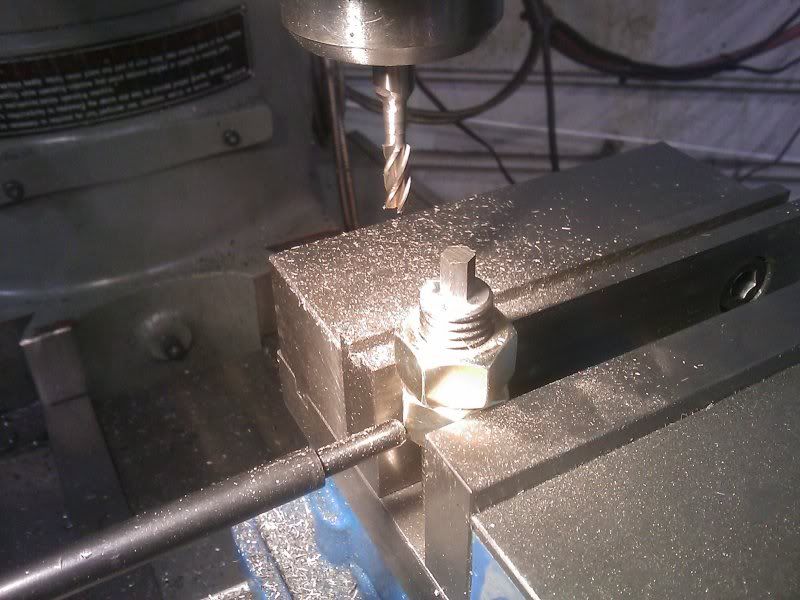

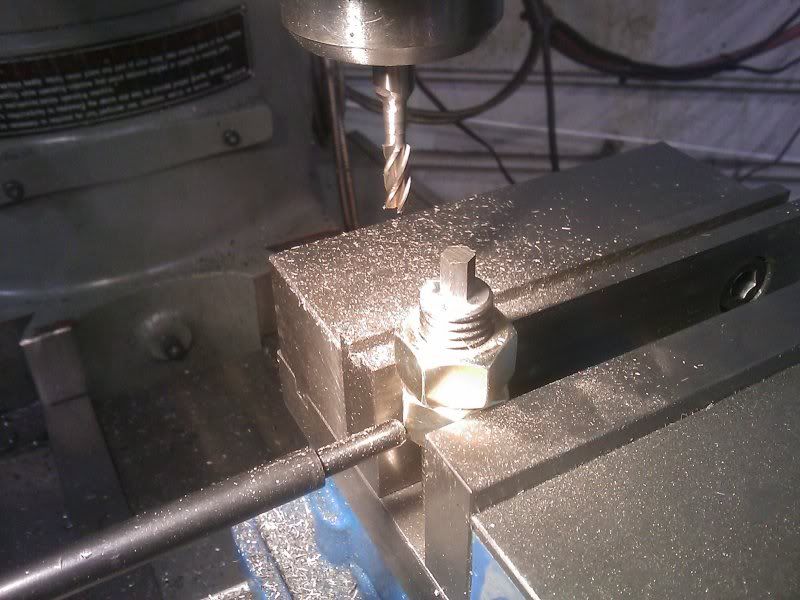

I made an adjustment stud for my steering arm. A standard 1/4" wrench fits the top hex. This will let me tune the pre-load for the kingpin cup. Its pretty neat what you can make even on a manual lathe with a little ingenuity.

I didn't get a pic, but I also machined the 'clocking' keyway splines on the WJ pitman arm. This will let me run the arm in any spline position on the dodge steering box.

Once my reamer and TRE's comes in I should be able to wrap the steering up. I still need to make the drag link and adjuster but that should be pretty easy on the lathe....

Yesterday I had an hour or two in the work shop.....

I made an adjustment stud for my steering arm. A standard 1/4" wrench fits the top hex. This will let me tune the pre-load for the kingpin cup. Its pretty neat what you can make even on a manual lathe with a little ingenuity.

I didn't get a pic, but I also machined the 'clocking' keyway splines on the WJ pitman arm. This will let me run the arm in any spline position on the dodge steering box.

Once my reamer and TRE's comes in I should be able to wrap the steering up. I still need to make the drag link and adjuster but that should be pretty easy on the lathe....

Last edited: