You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lee's '04 Chevy Silverado 2500HD and Radica MoonLander camping shell

- Thread starter Lee

- Start date

Thanks!Nice work on the awning install, that turned out really clean.

Regarding winch wiring, considering a switch/power disconnect? Also, thoughts on soldering vs crimps?

It turned out better than I originally thought it would, having extra time to think about it helped simplify the final product.

I have considered a mechanical switch under the hood to disconnect the winch.

There are a lot of examples out there using a solenoid to switch the main power off but I think a mechanical system would be more reliable (trading off a little convenience).

The final word in reliability is to re-wire around the switch if it fails.

I haven't looked in to it too much but Blue Sea makes a switch that looks about the right capacity.

I'm not sure if it is appropriate for under hood application (I'm guessing if it is marine rated it will probably be ok)

A switch would allow cutting off the power if something happens to the winch controller and it is stuck 'on'.

I have not seen this personally but I have seen two YouTube videos where this happened, and one of the guys at work had his winch suddenly turn on.

He was using the winch to hold a small boat on the roof - kind of a back up hooked to the front.

Apparently unbolting the battery post power in a hurry on the side of the road isn't fun.

As for soldering cables I'm not a fan.

Wires and cables on a vehicle are subject to a lot of vibration over the life of the vehicle.

A soldered joint is more likely to have a fatigue failure at the end of the solder.

Basically, how far the solder penetrates is not easily controlled, where a crimp with a boot or heat shrink tube has a more controlled strain relief on the wire / cable.

Also it's difficult to control the heat application when soldering a large cable.

I've tried to solder the battery leads on an older GM diesel before, the results where not good (obviously my lack of skill is a factor).

In the end I bought a OEM cable from the dealer.

My 'fix' had corrosion in the copper both sides of the solder, the combination of the stiff splice area and the copper strands disintegrating with green corrosion lead to a quick failure.

Last edited:

So, if you have been following along, there was a flurry of activity getting ready for our summer adventure to somewhere other than Ohio.

My employer shuts the factory down to do maintenance for the week at fourth of July and the engineering staff also gets off, there’s no reason for us to be off but I’m not complaining.

So I made plans to drive hard to New Mexico, two nights at Chaco Canyon and four nights in the Santa Fe National Forest with a few stops on the drive back to Ohio, all stuffed in to ten days (I added one vacation day at the front of the trip).

So, Friday morning we headed west to St Louis then I-44 South-West for Tulsa.

First tank of fuel with the new 52 gallon tank we went 650 miles before looking for fuel.

With the Moonlander shell, tires etc I get roughly 14 mpg, I need to recalculate with the addition of the hanger bars on both sides holding the awning and the shower tent, I expect some small reduction in mpg.

We stayed in a hotel in Tulsa so day two was going to be another long drive day, or not.

Starting out it was raining heavy but it soon cleared up, and when the road wasn’t wet I noticed we were smoking, grey smoke mostly on the right side.

So I pulled off at the next exit to check it out.

Everything was soaked in diesel from the engine back to the tailgate.

I spent several hours figuring out the exact source, it’s amazing how difficult this was to find and the 95* F with 95% humidity was not helping.

I started by checking everything I touched when I modified the fuel system – it seemed the logical place to start.

I even pulled the fuel filter off to make sure I didn’t leave the old o-ring on the fuel filter housing (I didn't).

Finally, I was sure it was coming from the right side of the engine, so I got a few cans of aerosol brake cleaner and washed that side of the engine.

Sitting in the park and ride lot at the toll road ramp I just couldn’t see any new fuel leaking but after driving one mile to the auto parts store the fuel was everywhere when I stopped.

Finally, with the engine cleaned off I revved the engine to 1500 rpm and went back to check.

Sure enough, it only leaked at elevated rpm, the jumper pipe from the diesel common rail to the injector was leaking at the injector connection.

So, we were in Chandler Oklahoma on a Saturday morning with a busted truck.

There was a Chevy dealer right at the exit ramp, my wife had walked over to use the facilities, and the sales guys had pity on her and entertained her in the air conditioning, but the service department would not be open till Monday.

Chandler OK is not large but they had everything we needed within walking distance.

We limped the truck over to the hotel in town, it’s one of the old hotels along route 66 with individual cabins.

It was old and a bit worn but the A/C worked great (probably still had R-12 freon in it).

We spent the rest of Saturday and Sunday wandering around town, they have a Route 66 interpretive center and a few restaurants (check out the enamel signs and old gas pumps at the bowling alley).

On Monday we walked to the Hertz office and rented a car, then took the truck over to the Chevy dealership.

Transferring stuff to the rental, I grabbed our clothes, food, anything with a lithium ion battery and the propane bottles, I figured there was no need to bake these items in the Oklahoma sun.

At this point we decided to go home, there was little prospect the dealer would get to our truck for a week or two and I didn’t have it in me to plan a rental drive and hotel trip on the fly.

And besides, I had had enough 'adventure' for the week.

On the drive home we did stop at the Chain of Rocks bridge over the Mississippi river just north of St Louis.

I had learned that this was the crossing for the old Route 66 even though it was a private toll bridge at the time.

Chain of Rocks bridge has a kink in the middle to accommodate where the bed rock would support the piers.

Must have been fun to meet a semi just as you got to the kink, yes trucks where smaller back then but still…

Today the bridge is maintained as a bicycle / foot bridge.

Three and a half weeks later the dealer called and told me the truck was ready to pick up.

The only issue was the jumper pipe, the injector end had split and simply replacing it fixed the issue, $430 was all but it's a system I am not familiar with so I don't regret letting the dealer take care of it.

I rented a car to run the trip in reverse, drove down Chandler, 823 miles, on a Thursday, picked up the truck and dropped the rental off on Friday morning.

I asked the parts guy if some one could pick me up at the rental place, one of the sales guys showed up with a brand new 2500 HD Silverado - if my wife had come with me I might have asked what kind of a deal could be made.

I spent $10 at the self car wash place trying to get the diesel off.

Then headed for home.

Along the way, I noticed the Green County Oklahoma Adventure Tour came within 12 miles of the Ok toll road.

I downloaded the GPS track from Overland Trail Guides to my Garmin and made a detour to catch about 25 miles of the GOAT (I know there is a missing letter but it’s what they say).

I stopped in a fairly remote area for this picture, it looks wide and well graveled but this was a repair to a washout.

I’m still getting used to east coast / mid-west overlanding, this trail was a basically a GPS track stitching together any dirt roads in the area.

There was one section that looked like my drive way – two dirt ruts with grass in the middle and, some guys house on one side and his barn on the other (I hope it was a public right-of-way).

But it’s fun to see the back side of the small communities along the way, there was a water hole with a dozen local kids having a swim.

One day I’ll go back and do the rest.

My employer shuts the factory down to do maintenance for the week at fourth of July and the engineering staff also gets off, there’s no reason for us to be off but I’m not complaining.

So I made plans to drive hard to New Mexico, two nights at Chaco Canyon and four nights in the Santa Fe National Forest with a few stops on the drive back to Ohio, all stuffed in to ten days (I added one vacation day at the front of the trip).

So, Friday morning we headed west to St Louis then I-44 South-West for Tulsa.

First tank of fuel with the new 52 gallon tank we went 650 miles before looking for fuel.

With the Moonlander shell, tires etc I get roughly 14 mpg, I need to recalculate with the addition of the hanger bars on both sides holding the awning and the shower tent, I expect some small reduction in mpg.

We stayed in a hotel in Tulsa so day two was going to be another long drive day, or not.

Starting out it was raining heavy but it soon cleared up, and when the road wasn’t wet I noticed we were smoking, grey smoke mostly on the right side.

So I pulled off at the next exit to check it out.

Everything was soaked in diesel from the engine back to the tailgate.

I spent several hours figuring out the exact source, it’s amazing how difficult this was to find and the 95* F with 95% humidity was not helping.

I started by checking everything I touched when I modified the fuel system – it seemed the logical place to start.

I even pulled the fuel filter off to make sure I didn’t leave the old o-ring on the fuel filter housing (I didn't).

Finally, I was sure it was coming from the right side of the engine, so I got a few cans of aerosol brake cleaner and washed that side of the engine.

Sitting in the park and ride lot at the toll road ramp I just couldn’t see any new fuel leaking but after driving one mile to the auto parts store the fuel was everywhere when I stopped.

Finally, with the engine cleaned off I revved the engine to 1500 rpm and went back to check.

Sure enough, it only leaked at elevated rpm, the jumper pipe from the diesel common rail to the injector was leaking at the injector connection.

So, we were in Chandler Oklahoma on a Saturday morning with a busted truck.

There was a Chevy dealer right at the exit ramp, my wife had walked over to use the facilities, and the sales guys had pity on her and entertained her in the air conditioning, but the service department would not be open till Monday.

Chandler OK is not large but they had everything we needed within walking distance.

We limped the truck over to the hotel in town, it’s one of the old hotels along route 66 with individual cabins.

It was old and a bit worn but the A/C worked great (probably still had R-12 freon in it).

We spent the rest of Saturday and Sunday wandering around town, they have a Route 66 interpretive center and a few restaurants (check out the enamel signs and old gas pumps at the bowling alley).

On Monday we walked to the Hertz office and rented a car, then took the truck over to the Chevy dealership.

Transferring stuff to the rental, I grabbed our clothes, food, anything with a lithium ion battery and the propane bottles, I figured there was no need to bake these items in the Oklahoma sun.

At this point we decided to go home, there was little prospect the dealer would get to our truck for a week or two and I didn’t have it in me to plan a rental drive and hotel trip on the fly.

And besides, I had had enough 'adventure' for the week.

On the drive home we did stop at the Chain of Rocks bridge over the Mississippi river just north of St Louis.

I had learned that this was the crossing for the old Route 66 even though it was a private toll bridge at the time.

Chain of Rocks bridge has a kink in the middle to accommodate where the bed rock would support the piers.

Must have been fun to meet a semi just as you got to the kink, yes trucks where smaller back then but still…

Today the bridge is maintained as a bicycle / foot bridge.

Three and a half weeks later the dealer called and told me the truck was ready to pick up.

The only issue was the jumper pipe, the injector end had split and simply replacing it fixed the issue, $430 was all but it's a system I am not familiar with so I don't regret letting the dealer take care of it.

I rented a car to run the trip in reverse, drove down Chandler, 823 miles, on a Thursday, picked up the truck and dropped the rental off on Friday morning.

I asked the parts guy if some one could pick me up at the rental place, one of the sales guys showed up with a brand new 2500 HD Silverado - if my wife had come with me I might have asked what kind of a deal could be made.

I spent $10 at the self car wash place trying to get the diesel off.

Then headed for home.

Along the way, I noticed the Green County Oklahoma Adventure Tour came within 12 miles of the Ok toll road.

I downloaded the GPS track from Overland Trail Guides to my Garmin and made a detour to catch about 25 miles of the GOAT (I know there is a missing letter but it’s what they say).

I stopped in a fairly remote area for this picture, it looks wide and well graveled but this was a repair to a washout.

I’m still getting used to east coast / mid-west overlanding, this trail was a basically a GPS track stitching together any dirt roads in the area.

There was one section that looked like my drive way – two dirt ruts with grass in the middle and, some guys house on one side and his barn on the other (I hope it was a public right-of-way).

But it’s fun to see the back side of the small communities along the way, there was a water hole with a dozen local kids having a swim.

One day I’ll go back and do the rest.

@rgv, you got that right.

When I initially stopped and I saw how much diesel was covering the underside of the truck I was a little sketched out.

I told the wife to grab the fire extinguisher and hop out, but honestly, if it had started to burn I doubt we would have saved it.

I’ve only been present for one serious car fire many years ago (another person in the group).

There truck had a new engine put in it before a trip to Baja, engine caught fire on the toll road returning from Ensenada.

Four or five fire extinguishers later the truck burned to the ground, even the alloy wheels where consumed.

I’m thinking I need to up my ‘what it’ game.

First I need to think more seriously about a bail out bag, what do I need to survive if it all goes south while remote.

Also, what I would want on the side of the interstate might be different than what is needed in Death Valley in July (pro tip, don’t go there in July).

And I am thinking I want to invest in a few of the ‘Element’ fire extinguishers, it looks like a road flare where the smoke deprives a fire of oxygen.

In a case were the underside of a vehicle is covered in fuel and burning this type of extinguisher could be tossed underneath letting the smoke rise and spread out under the vehicle.

(if someone has knowledge of that type of extinguisher or a good reference feel free to comment)

Oh, and, next time I’m pulling over right away, not the next exit…

When I initially stopped and I saw how much diesel was covering the underside of the truck I was a little sketched out.

I told the wife to grab the fire extinguisher and hop out, but honestly, if it had started to burn I doubt we would have saved it.

I’ve only been present for one serious car fire many years ago (another person in the group).

There truck had a new engine put in it before a trip to Baja, engine caught fire on the toll road returning from Ensenada.

Four or five fire extinguishers later the truck burned to the ground, even the alloy wheels where consumed.

I’m thinking I need to up my ‘what it’ game.

First I need to think more seriously about a bail out bag, what do I need to survive if it all goes south while remote.

Also, what I would want on the side of the interstate might be different than what is needed in Death Valley in July (pro tip, don’t go there in July).

And I am thinking I want to invest in a few of the ‘Element’ fire extinguishers, it looks like a road flare where the smoke deprives a fire of oxygen.

In a case were the underside of a vehicle is covered in fuel and burning this type of extinguisher could be tossed underneath letting the smoke rise and spread out under the vehicle.

(if someone has knowledge of that type of extinguisher or a good reference feel free to comment)

Oh, and, next time I’m pulling over right away, not the next exit…

When I added the 52-gallon Titan fuel tank I was not impressed with the vent hose situation (full disclosure – it’s not what I am currently doing but I have years of experience designing these systems for my employer).

The instructions say something about running the two hoses up hill and keeping the end above the top of the tank.

In my case the hoses didn’t seem long enough so I compensated with more zip ties to stretch them out as long as possible.

When filling the tank a little fuel sloshed out, the hose has a check valve but the slosh was not sufficient to trigger the valve.

Also the end fitting was a screen that seemed appropriate to keep out small birds but not dust.

The problem with working for an OEM auto maker is I can easily design what my employer would use to vent the next million cars off the assembly line.

But to design something for a one off that I then have to fabricate with the skill set I have (I’m an engineer so that would be ‘very limited skill set’) takes a little more thought.

I settled on a bracket to hold the vents up inside the front end of the bedside with K&N crankcase vent filters on the end.

I’m usually not a fan of K&N but in this case the 2” diameter fit what I needed and with very low air flow requirements it should be ok.

I ordered fuel hose to match the vent hoses, brass couplers and crimp on hose clamps and, while I was at it, vent tubing to match the rear diff breather and a brass coupler for the breather.

The bracket is a simple plate with the edges turned up to add stiffness, and two platforms are welded on to hold the filters, the bracket is bolted at the bottom (where I have room to get my hands in there) and it extends up inside the bedside to get the vents above the waterline.

On the back side near the top is a piece of rubber weatherstripping to prevent the end away from the bolts from vibrating and making a mystery noise while driving down the freeway.

The filters are high enough that if they are submerged I have bigger problems than water in the tank.

Cutting out the platforms:

The hoses will be zip tied to the edges of the bracket.

For deburring holes I really like these counter sinks.

They do not chatter like the old style counter sinks that have four or five fluted cutting edges.

With only one cutting edge they are a little slower at removing material – making it easier for me to control.

The hose and the filter sandwich the bracket platform with a rubber gromet to hold the assembly together.

To reduce the risk of fuel sloshing up, washing the filter media and then back flowing to the tank the brass coupler extends above the bottom of the filter.

Here the bracket is fully dressed, I connected both ends of the fuel vent hose so I could cut it to size in place and have one leftover piece.

Also you can see the diff breather hose sneaking up the center of the bracket, the stock end cap is located beside the upper vent filter.

I have the parts to move the front diff breather and the transmission/transfer case breathers (although I have not checked to make sure they use the same size tubing yet).

This is the finished installation, looking up from below (and you can see my magnetic work light on the inside of the bedside).

It looks a little more sanitary up there.

The wire harness is for the ARB compressor mounted inside the bed.

I used a zip tie in a figure 8 configuration with a short length of fuel hose to attach the harness to the fill hose.

I don’t think the performance will be noticeably different but I feel better without the rat’s nest of zip ties under there.

The instructions say something about running the two hoses up hill and keeping the end above the top of the tank.

In my case the hoses didn’t seem long enough so I compensated with more zip ties to stretch them out as long as possible.

When filling the tank a little fuel sloshed out, the hose has a check valve but the slosh was not sufficient to trigger the valve.

Also the end fitting was a screen that seemed appropriate to keep out small birds but not dust.

The problem with working for an OEM auto maker is I can easily design what my employer would use to vent the next million cars off the assembly line.

But to design something for a one off that I then have to fabricate with the skill set I have (I’m an engineer so that would be ‘very limited skill set’) takes a little more thought.

I settled on a bracket to hold the vents up inside the front end of the bedside with K&N crankcase vent filters on the end.

I’m usually not a fan of K&N but in this case the 2” diameter fit what I needed and with very low air flow requirements it should be ok.

I ordered fuel hose to match the vent hoses, brass couplers and crimp on hose clamps and, while I was at it, vent tubing to match the rear diff breather and a brass coupler for the breather.

The bracket is a simple plate with the edges turned up to add stiffness, and two platforms are welded on to hold the filters, the bracket is bolted at the bottom (where I have room to get my hands in there) and it extends up inside the bedside to get the vents above the waterline.

On the back side near the top is a piece of rubber weatherstripping to prevent the end away from the bolts from vibrating and making a mystery noise while driving down the freeway.

The filters are high enough that if they are submerged I have bigger problems than water in the tank.

Cutting out the platforms:

The hoses will be zip tied to the edges of the bracket.

For deburring holes I really like these counter sinks.

They do not chatter like the old style counter sinks that have four or five fluted cutting edges.

With only one cutting edge they are a little slower at removing material – making it easier for me to control.

The hose and the filter sandwich the bracket platform with a rubber gromet to hold the assembly together.

To reduce the risk of fuel sloshing up, washing the filter media and then back flowing to the tank the brass coupler extends above the bottom of the filter.

Here the bracket is fully dressed, I connected both ends of the fuel vent hose so I could cut it to size in place and have one leftover piece.

Also you can see the diff breather hose sneaking up the center of the bracket, the stock end cap is located beside the upper vent filter.

I have the parts to move the front diff breather and the transmission/transfer case breathers (although I have not checked to make sure they use the same size tubing yet).

This is the finished installation, looking up from below (and you can see my magnetic work light on the inside of the bedside).

It looks a little more sanitary up there.

The wire harness is for the ARB compressor mounted inside the bed.

I used a zip tie in a figure 8 configuration with a short length of fuel hose to attach the harness to the fill hose.

I don’t think the performance will be noticeably different but I feel better without the rat’s nest of zip ties under there.

Quick update:

Vent for the front diff and the transfer case brought up high under the hood on the drivers side.

The transmission is still a work in progress, it will require a new press in nipple.

Again I just extended the existing hose with a brass connector and some rubber vacuum hose.

And I moved the existing end cap to it's new home.

FYI, I keep seeing the interweb wanting to call the end fitting a one way valve.

It's not, it's just a cover to keep debris from falling in, there is no ability to stop air flow in or out.

Side note, I have seen differentials puke oil twice - The oil will boil and it comes out with a vengeance.

If the front diff ever where to do that it will make a huge mess under the hood before blowing the hose off the nipple at the diff housing.

But it is rare and I do not plan to mess with the diff internals so the chance of this is extremely low.

I also bolted on a Mechmann 250A alternator.

This is rated at 180 amps at idle.

That should be able to handle the compressor and a power station charger while airing up the tires.

The new alternator case is larger than the stock 105 amp unit, the A/C hose now rests on the case.

I probably should look at replacing the main power lead but currently I am drawing less total power than the max the old system was rated at.

It's just now I have the ability to go crazy so updating the system to match is probably a good idea.

Also, while I was at it I replaced the belt - but wait there's more!

While looking for a Gates belt I found a kit from Gates that had the two idler pullies and a new tensioner pully so I replaced them all.

Vent for the front diff and the transfer case brought up high under the hood on the drivers side.

The transmission is still a work in progress, it will require a new press in nipple.

Again I just extended the existing hose with a brass connector and some rubber vacuum hose.

And I moved the existing end cap to it's new home.

FYI, I keep seeing the interweb wanting to call the end fitting a one way valve.

It's not, it's just a cover to keep debris from falling in, there is no ability to stop air flow in or out.

Side note, I have seen differentials puke oil twice - The oil will boil and it comes out with a vengeance.

If the front diff ever where to do that it will make a huge mess under the hood before blowing the hose off the nipple at the diff housing.

But it is rare and I do not plan to mess with the diff internals so the chance of this is extremely low.

I also bolted on a Mechmann 250A alternator.

This is rated at 180 amps at idle.

That should be able to handle the compressor and a power station charger while airing up the tires.

The new alternator case is larger than the stock 105 amp unit, the A/C hose now rests on the case.

I probably should look at replacing the main power lead but currently I am drawing less total power than the max the old system was rated at.

It's just now I have the ability to go crazy so updating the system to match is probably a good idea.

Also, while I was at it I replaced the belt - but wait there's more!

While looking for a Gates belt I found a kit from Gates that had the two idler pullies and a new tensioner pully so I replaced them all.

Pacific Northwest yetti

Expedition Medic

Do the D max, of this year have issues with the fuel Evap Canister?

The gassers did, and the dealer fix was to reroute the canister under the hood.

It may have been something you addressed when working with the other fuel vent lines and just missed it *

The gassers did, and the dealer fix was to reroute the canister under the hood.

It may have been something you addressed when working with the other fuel vent lines and just missed it *

There is no canister on this model.Do the D max, of this year have issues with the fuel Evap Canister?

I only know about the LB7 (mine is an early 2004 model) the fuel system is vented to atmosphere at the filler cap.

So I had seen that 4 wheel Camper’s project M demo installed a Bed Rug to clean up the bed tub and provide better sealing in the living space of the camper.

Most of my sealing is from duct taping all the holes in the bed and applying weatherstripping around the tail gate but I liked the idea of having the interior carpet.

But there is a certain level of ‘finished’ that was needed before I was ready to install the Bed Rug.

The Bed Rug kit comes with a bottom mat that has the rib pattern of the bed floor with a flap to cover the tailgate and a one-piece surround that covers the sides and the front panel.

The two parts zip together to form a form fitted covering for all of the bed interior.

Picture below shows the Bed Rug fitted around the air compressor and the air tank.

Basically, I cut holes in the rug to fit around the components mounted inside the bed.

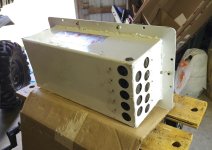

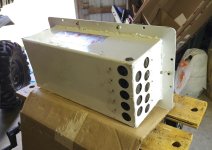

In the opposite corner is my box for the heater.

The heater box has been a pain in the backside and the cause of much of the delays in getting the Bed Rug installed.

You can see the start of cutting the hole for it in post #40 from June of last year (the time lag is relevant to the issues from last week).

The heater box, with heater installed, you can see the control/power wires coming through a slot in the box lid and the duct coming into the bed living space (the heavy cables are for the powers station charger – more later).

The plan was to make a box that would keep the diesel heater and its fuel outside of the living space.

The box has a series of holes near the front inlet side of the heater that are covered with a roving to keep out debris, the roving is leftover from the barn roof, it’s intended to stop birds nesting between the metal roof and flashing.

The outlet pipe is sealed with a rubber diaphragm that is sandwiched with a ring to the box, a hole in the rubber seals to the duct. (I'll explain the discrepancy between the plan and the pictures in a moment)

When I started the process I made detailed sketches of the box while sitting inside the bed.

Then I cut out the parts but I did not bend / weld the box at that time.

After setting the project down for a year I picked up the parts and finish making the box.

But I did all the bending and welding while standing outside the bed, so every time I looked at the truck I had the parts inverted.

When I did the first test fit, drop the box in to the hole in the side of the bed, put the heater into the box – the heater was facing the wrong way.

So I flipped the box, redrilled the holes in the bottom and the outlet hole in the end.

This left extra holes in the box that needed to be covered but it saved a year in fabrication time (not really – it would be procrastination time).

The set of holes to mount the heater now on the top are covered with foil duct tape and the end hole was covered with the rubber diaphragm that seals the outlet tube.

It’s a little janky but it’s functional, installed and not readily visible – I can live with it.

Pictures show the box posing with he heater unit placed inside, the cover that forms the inside wall of the truck bed is hanging below in the photo above.

I found a rubberized fiberglass strand reinforces heater duct that is the same size as the paper and foil hot air duct that came in the kit from Espar.

The short section from the heater box to the hole in the bedside is protected by the wheel well but this should provide the protection needed from the environment.

The Bed Rug covers the heater box, if I can’t fold the rug down sufficiently to access the cover for maintenance I will cut a flap and glue it to the cover but that is a job for another day.

The heater outlet entrance to the bed is in to a T with flow control valves on both sides.

I plan to heat the stuff under the bed, mainly my water storage, to act as a thermal flywheel so the heater is not trying to short cycle on and off.

I don’t have hard data for this, it’s a guess on my part.

All of my experience with HVAC is trying to heat or cool a seemingly infinite heat sink – at least that is how it feels when designing for an uninsulated vehicle with a target for a hot day in Georgia (High temp and high humidity and plenty of solar radiation) or a cold day in Minnesota (just plain cold with plenty of wind to improve heat transfer).

Next along the passenger side of the bed is a Bluetti Charger 1 for the Zero Breeze Elechive power station.

The Charger 1 plugs in to the solar port and mimics a 560-Watt solar panel.

I used a molle panel from Builtright as the mount, the charger bolts on and the circuit breaker and wires are mounted to keep things together and tidy.

The molle was an experiment, probably a chunk of peg board would have done the same job and cost a lot less but there are still options to mount other things to the molle.

While I was at it I also ordered a 17" X 17" molle for the driver’s side of the bed.

This one needed some modification to fit in this location.

I chopped out the bottom corner near the wheel well and a strip to allow the panel to be bent around the stake pocket.

I used Builtright because of their YouTube videos showing their design process.

There may be cheaper alternatives out there, but I didn’t mind supporting them.

Side story.

We are working on something at work that requires modular storage.

The typical solution is to make some proprietary storage that only works in one application – it’s a business so I get that.

I kept telling the kids I work with to throw some molle on there and tell everyone it’s just holes to make it lighter.

And they looked at me like I was some old fuddy-duddy that was losing it.

So I ordered the small composite tech plate that Builtright sells as a into / advertising sample that includes bolt mounts, stand offs ect.

While the kids were out at lunch one day I pulled the cordless drill out of my computer bag and mounted the Tech Plate to this kids desk and wove on a surplus single clip molle pouch.

I think I got my point across.

Most of my sealing is from duct taping all the holes in the bed and applying weatherstripping around the tail gate but I liked the idea of having the interior carpet.

But there is a certain level of ‘finished’ that was needed before I was ready to install the Bed Rug.

The Bed Rug kit comes with a bottom mat that has the rib pattern of the bed floor with a flap to cover the tailgate and a one-piece surround that covers the sides and the front panel.

The two parts zip together to form a form fitted covering for all of the bed interior.

Picture below shows the Bed Rug fitted around the air compressor and the air tank.

Basically, I cut holes in the rug to fit around the components mounted inside the bed.

In the opposite corner is my box for the heater.

The heater box has been a pain in the backside and the cause of much of the delays in getting the Bed Rug installed.

You can see the start of cutting the hole for it in post #40 from June of last year (the time lag is relevant to the issues from last week).

The heater box, with heater installed, you can see the control/power wires coming through a slot in the box lid and the duct coming into the bed living space (the heavy cables are for the powers station charger – more later).

The plan was to make a box that would keep the diesel heater and its fuel outside of the living space.

The box has a series of holes near the front inlet side of the heater that are covered with a roving to keep out debris, the roving is leftover from the barn roof, it’s intended to stop birds nesting between the metal roof and flashing.

The outlet pipe is sealed with a rubber diaphragm that is sandwiched with a ring to the box, a hole in the rubber seals to the duct. (I'll explain the discrepancy between the plan and the pictures in a moment)

When I started the process I made detailed sketches of the box while sitting inside the bed.

Then I cut out the parts but I did not bend / weld the box at that time.

After setting the project down for a year I picked up the parts and finish making the box.

But I did all the bending and welding while standing outside the bed, so every time I looked at the truck I had the parts inverted.

When I did the first test fit, drop the box in to the hole in the side of the bed, put the heater into the box – the heater was facing the wrong way.

So I flipped the box, redrilled the holes in the bottom and the outlet hole in the end.

This left extra holes in the box that needed to be covered but it saved a year in fabrication time (not really – it would be procrastination time).

The set of holes to mount the heater now on the top are covered with foil duct tape and the end hole was covered with the rubber diaphragm that seals the outlet tube.

It’s a little janky but it’s functional, installed and not readily visible – I can live with it.

Pictures show the box posing with he heater unit placed inside, the cover that forms the inside wall of the truck bed is hanging below in the photo above.

I found a rubberized fiberglass strand reinforces heater duct that is the same size as the paper and foil hot air duct that came in the kit from Espar.

The short section from the heater box to the hole in the bedside is protected by the wheel well but this should provide the protection needed from the environment.

The Bed Rug covers the heater box, if I can’t fold the rug down sufficiently to access the cover for maintenance I will cut a flap and glue it to the cover but that is a job for another day.

The heater outlet entrance to the bed is in to a T with flow control valves on both sides.

I plan to heat the stuff under the bed, mainly my water storage, to act as a thermal flywheel so the heater is not trying to short cycle on and off.

I don’t have hard data for this, it’s a guess on my part.

All of my experience with HVAC is trying to heat or cool a seemingly infinite heat sink – at least that is how it feels when designing for an uninsulated vehicle with a target for a hot day in Georgia (High temp and high humidity and plenty of solar radiation) or a cold day in Minnesota (just plain cold with plenty of wind to improve heat transfer).

Next along the passenger side of the bed is a Bluetti Charger 1 for the Zero Breeze Elechive power station.

The Charger 1 plugs in to the solar port and mimics a 560-Watt solar panel.

I used a molle panel from Builtright as the mount, the charger bolts on and the circuit breaker and wires are mounted to keep things together and tidy.

The molle was an experiment, probably a chunk of peg board would have done the same job and cost a lot less but there are still options to mount other things to the molle.

While I was at it I also ordered a 17" X 17" molle for the driver’s side of the bed.

This one needed some modification to fit in this location.

I chopped out the bottom corner near the wheel well and a strip to allow the panel to be bent around the stake pocket.

I used Builtright because of their YouTube videos showing their design process.

There may be cheaper alternatives out there, but I didn’t mind supporting them.

Side story.

We are working on something at work that requires modular storage.

The typical solution is to make some proprietary storage that only works in one application – it’s a business so I get that.

I kept telling the kids I work with to throw some molle on there and tell everyone it’s just holes to make it lighter.

And they looked at me like I was some old fuddy-duddy that was losing it.

So I ordered the small composite tech plate that Builtright sells as a into / advertising sample that includes bolt mounts, stand offs ect.

While the kids were out at lunch one day I pulled the cordless drill out of my computer bag and mounted the Tech Plate to this kids desk and wove on a surplus single clip molle pouch.

I think I got my point across.

The elephant in the room (no literary, this thing is huge).

I think for me there are two game changers for this build.

One is the Moonlander shell that has east west bed that allows space at the back of the shell inside.

I can set a chair up and sit inside out of the weather – a contractor’s cap from ARE would not have this functionality with a queen size bed.

The second is a bed slide that is only under the bed.

Without the slide I was packing stuff under the bed in four rows, the two rows closest to the front of the bed were not packed tight because I could not access them, so only low usage items went up there.

And the fourth row was taking up the open space at the tail gate making the advantage of the east west bed useless.

I posted this picture last year, it shows the rig packed for a week in Colorado.

The white thing on the left is a room air conditioner (with a carpet thrown over it) that has been replaced with a much more compact Zero Breeze mark 3 portable A/C – so some items are more compact.

The slide is from Cargo Glide, now a part of Decked.

When I first started to research bed slides the ‘Cargo Glide’ YouTube ad had a great sound effect as the slide picked up the middle extension frame with a solid sounding clunk.

I guess it made an impression.

They have a ‘hold my beer’ page (no really, that is what they call it on their website) where they give the dimensions of the various bed slides for different vehicles.

The bed slide intended for the Jeep Gladiator just about fit the bill for what I wanted, it’s length was a good fit for the sleeping platform, and the width did not fill the space between the wheel wells leaving room for my water storage.

Originally I was planning to use a custom sized slide that had 120% extension, this would have brought the rear of the slide out to middle of the tailgate making access very good.

As it is, with just 100% extension the rear of the slide is still accessible when standing on the ground and I saved about a third of the cost or about $1k.

The unit weighs around 230 pounds, it has a substantial steel frame that bolts to the bed and a secondary frame between the base and the slide allowing 100% extension.

There is a third minor con to the setup, the deck is about 4” above the bed of the truck.

In my case I have an extra-large Milwaukee Packout case that no longer fits.

I separated the base using an engine hoist to hold the slide and secondary frame and cut the bed rug to fit around the feet.

The instructions specifically say not to use a bed rug but I’m going the hold my beer route – so far so good.

The bed rug does not foul the rollers and with an ‘indoor’ application I’m hoping the rug has fewer loose fibers to get caught up in the mechanism.

All of my pictures show the slide loaded.

As soon as it was in, I loaded it up and tried different configurations trying to figure out how to load it.

Showing the driver’s side with the bed slide extended.

So I know having the traction boards inside is not ideal.

I have on order a hitch mounted tire carrier with accessories to mount the hi-Lift jack, shovel, GP Factor traction board mount (base plate under the spare tire and the boards riding piggyback on the tire) and a place to bolt on my ammo box with chemicals that I don’t want in the sleeping space.

But until my RiG’d UltraSwing arrives I need to find other places to stash stuff.

Not quite the clear area I wanted but I’m getting there.

I think for me there are two game changers for this build.

One is the Moonlander shell that has east west bed that allows space at the back of the shell inside.

I can set a chair up and sit inside out of the weather – a contractor’s cap from ARE would not have this functionality with a queen size bed.

The second is a bed slide that is only under the bed.

Without the slide I was packing stuff under the bed in four rows, the two rows closest to the front of the bed were not packed tight because I could not access them, so only low usage items went up there.

And the fourth row was taking up the open space at the tail gate making the advantage of the east west bed useless.

I posted this picture last year, it shows the rig packed for a week in Colorado.

The white thing on the left is a room air conditioner (with a carpet thrown over it) that has been replaced with a much more compact Zero Breeze mark 3 portable A/C – so some items are more compact.

The slide is from Cargo Glide, now a part of Decked.

When I first started to research bed slides the ‘Cargo Glide’ YouTube ad had a great sound effect as the slide picked up the middle extension frame with a solid sounding clunk.

I guess it made an impression.

They have a ‘hold my beer’ page (no really, that is what they call it on their website) where they give the dimensions of the various bed slides for different vehicles.

The bed slide intended for the Jeep Gladiator just about fit the bill for what I wanted, it’s length was a good fit for the sleeping platform, and the width did not fill the space between the wheel wells leaving room for my water storage.

Originally I was planning to use a custom sized slide that had 120% extension, this would have brought the rear of the slide out to middle of the tailgate making access very good.

As it is, with just 100% extension the rear of the slide is still accessible when standing on the ground and I saved about a third of the cost or about $1k.

The unit weighs around 230 pounds, it has a substantial steel frame that bolts to the bed and a secondary frame between the base and the slide allowing 100% extension.

There is a third minor con to the setup, the deck is about 4” above the bed of the truck.

In my case I have an extra-large Milwaukee Packout case that no longer fits.

I separated the base using an engine hoist to hold the slide and secondary frame and cut the bed rug to fit around the feet.

The instructions specifically say not to use a bed rug but I’m going the hold my beer route – so far so good.

The bed rug does not foul the rollers and with an ‘indoor’ application I’m hoping the rug has fewer loose fibers to get caught up in the mechanism.

All of my pictures show the slide loaded.

As soon as it was in, I loaded it up and tried different configurations trying to figure out how to load it.

Showing the driver’s side with the bed slide extended.

So I know having the traction boards inside is not ideal.

I have on order a hitch mounted tire carrier with accessories to mount the hi-Lift jack, shovel, GP Factor traction board mount (base plate under the spare tire and the boards riding piggyback on the tire) and a place to bolt on my ammo box with chemicals that I don’t want in the sleeping space.

But until my RiG’d UltraSwing arrives I need to find other places to stash stuff.

Not quite the clear area I wanted but I’m getting there.

My plan for water storage is to locate it here next to the heater vent.

In the past I used 5 gallon water jugs from Reliance – 3 of the blue cube shaped ones and one old one that was round.

They served me well, I think the oldest one is pushing 40 years old from our first camping trips when I got married (can I really be that old?).

But recently I got one 11-liter (~3 gallons) Dometic Go-Hydration water jug and it’s just better so I bought 3 more.

The spout is sealed with an O-ring so it can be pointed down independent of how well it’s screwed on.

And they have an attachment for a remote water hose that I have not quite figured how I will use it.

I really want to connect them in series so as I empty the first one it is refilled from the last one.

On the downside they are really expensive.

Also I have not figured out how I will mount them yet.

Several companies make really flash looking aluminum mounts that are also really expensive.

Dometic says they will fit two to a jerry can mount – like the old style army jeep ones.

In my mind those should be $5 at the swap meet (grew up in the south bay LA area going to the Roadium drive in swap meet with the rocket standing behind the screen).

A quick check of Google maps and the Roadium is still there but the rocket and the $5 jerry can mounts are gone.

For now a tie down strap snugging them to the wheel well will suffice.

In the past I used 5 gallon water jugs from Reliance – 3 of the blue cube shaped ones and one old one that was round.

They served me well, I think the oldest one is pushing 40 years old from our first camping trips when I got married (can I really be that old?).

But recently I got one 11-liter (~3 gallons) Dometic Go-Hydration water jug and it’s just better so I bought 3 more.

The spout is sealed with an O-ring so it can be pointed down independent of how well it’s screwed on.

And they have an attachment for a remote water hose that I have not quite figured how I will use it.

I really want to connect them in series so as I empty the first one it is refilled from the last one.

On the downside they are really expensive.

Also I have not figured out how I will mount them yet.

Several companies make really flash looking aluminum mounts that are also really expensive.

Dometic says they will fit two to a jerry can mount – like the old style army jeep ones.

In my mind those should be $5 at the swap meet (grew up in the south bay LA area going to the Roadium drive in swap meet with the rocket standing behind the screen).

A quick check of Google maps and the Roadium is still there but the rocket and the $5 jerry can mounts are gone.

For now a tie down strap snugging them to the wheel well will suffice.

As a temporary measure I mounted my Hi-Lift jack to the top of the bull bar.

I have seen several full-size rigs doing this, like the Overland Trail Guide guy.

It’s not my favorite solution but was easy and it works while waiting for my tire carrier to show up.

I stopped at Tractor Supply Co and picked up a length of ½” all thread and a few nuts and washers.

I had some square nuts from an antique tractor project left over so I used those as the support for the jack.

The square nuts won’t turn when next to the jacks main bar so it makes adjustment easy.

In a perfect solution a wing nut would make the perfect top nut but I didn’t have any and this was supposed to be a temporary set up so a regular hex nut went on top.

If I need to use the jack, taking a minute to find a wrench to get the jack off is probably a good thing – just a few moments to think things through.

Having driven a little bit with the jack on the bull bar I have given it way too much thought.

At first I was concerned that the jack mechanism would get wet if it rained.

I have had this jack for ~40 years and it has only recently ridden inside the shell (bolted down).

The WD40 is packed with my recovery gear so water just isn’t a problem.

Side note – the key to Hi-Lift jack usage is to clean the climbing mechanism out with WD40 before use.

It removes the dirt and lubricates pins.

Then I started to wonder if the bar is bent.

It is actually, not sure how / when that happened but it’s been traveling with several vehicles and doing farm duty for the last 20 years so I’m not surprised.

I really think putting the jack out of sight – around back – is the better solution.

Out of sight, out of mind.

View out the front, Picacho Peak outside of Tucson on the left with the first rays of sun hitting the hills on the right.

I have seen several full-size rigs doing this, like the Overland Trail Guide guy.

It’s not my favorite solution but was easy and it works while waiting for my tire carrier to show up.

I stopped at Tractor Supply Co and picked up a length of ½” all thread and a few nuts and washers.

I had some square nuts from an antique tractor project left over so I used those as the support for the jack.

The square nuts won’t turn when next to the jacks main bar so it makes adjustment easy.

In a perfect solution a wing nut would make the perfect top nut but I didn’t have any and this was supposed to be a temporary set up so a regular hex nut went on top.

If I need to use the jack, taking a minute to find a wrench to get the jack off is probably a good thing – just a few moments to think things through.

Having driven a little bit with the jack on the bull bar I have given it way too much thought.

At first I was concerned that the jack mechanism would get wet if it rained.

I have had this jack for ~40 years and it has only recently ridden inside the shell (bolted down).

The WD40 is packed with my recovery gear so water just isn’t a problem.

Side note – the key to Hi-Lift jack usage is to clean the climbing mechanism out with WD40 before use.

It removes the dirt and lubricates pins.

Then I started to wonder if the bar is bent.

It is actually, not sure how / when that happened but it’s been traveling with several vehicles and doing farm duty for the last 20 years so I’m not surprised.

I really think putting the jack out of sight – around back – is the better solution.

Out of sight, out of mind.

View out the front, Picacho Peak outside of Tucson on the left with the first rays of sun hitting the hills on the right.

Last edited: