sallf

Member

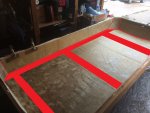

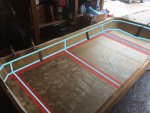

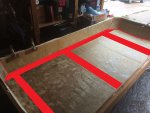

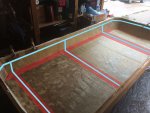

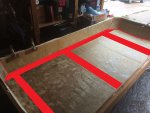

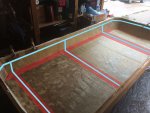

Laid the first 2 layers of glass this week. I definitely have some spots to sand down, but overall think we did pretty good! The only thing I would have done differently might have been to have some mylar wrapped pieces of plywood ready to help compress the edges. There were a few spots where the fabric kept wanting to peel away which was an inconvenience. You'll notice a couple spots that I've clamped. I might even recommend cutting enough to cover all the edges. We'll see what it looks like when it actually gets out of the mold.

Threw a quick timelapse together as I thought it might be a good way to see what was and was not working:

More info on the process:

- We mixed 15 cc's per pint of polyester resin which seemed to work well (about 65 degrees outside).

- Disposable brushes to blot, paint rollers to spread and steel rollers to compress.

- Laid 2 layers of 1.5 oz fiberglass mat. Plan on doing another 3 after I add internal reinforcements.

I've spent most of my day today thinking about how to add reinforcements/stringers, mount my rack, add a lifting mechanism and attach the canvas sides. Ultimately I keep drawing up designs that look like @boll_rig 's setup except I'm thinking I might do a manual lift with pneumatic struts. I know @rayra has mentioned using conduit. I like the idea of being able to use threaded connectors but bolting and wrapping the circular conduit seems challenging.

This is where I currently am in my thought process and would love any feedback!

Step 1: 1/2" or 3/4" Plywood (or maybe deck composite since it won't rot)

- Lay two verticals and a few cross supports.

- Reinforce corners with dowels.

- Wood is definitely easier for me to work with. My only concern is a lot of people have been talking about wood rot in fiberglass, but that's mostly on boat forms and I guess I'm not too worried out here in dry Colorado.

Step 2: Lay final 3 layers of glass to seal that in

Step 3: Square tube or "c" channel frame.

- This will not be glassed in.

- Canvas can screw to inner edges.

- Pneumatic lift can attach to bottom edge (I hope)

Step 4: Add a couple more supports since the frame will be lifting the top

Step 5: Pull from mold, flip, add two strips of stainless steel to to the top to reinforce where the rack will sit, and glass that in

- Rack would either:

1. Bolt all the way through (this makes me nervous because of having to seal it)

2. Attach weld nuts to the top and use them to bolt to the rack (would still run some carriage bolts all the way through the stainless steel strips to make sure they are secure, but would glass over them to seal it in)

I'm hoping to do pneumatic struts similar to the build @DAlgozine posted. Anyone know where to get some like this? I'm hoping to lift about 4 feet and am guessing that means I need some that are about 5 feet extended?

Any other thoughts or advice would be greatly appreciated! Biggest concerns right now are:

1. Wood rot.

2. Sealing any holes I drill through.

3. Finding struts that will lift the top ~4 feet.

TL;DR It's moving forward .

.

Threw a quick timelapse together as I thought it might be a good way to see what was and was not working:

More info on the process:

- We mixed 15 cc's per pint of polyester resin which seemed to work well (about 65 degrees outside).

- Disposable brushes to blot, paint rollers to spread and steel rollers to compress.

- Laid 2 layers of 1.5 oz fiberglass mat. Plan on doing another 3 after I add internal reinforcements.

I've spent most of my day today thinking about how to add reinforcements/stringers, mount my rack, add a lifting mechanism and attach the canvas sides. Ultimately I keep drawing up designs that look like @boll_rig 's setup except I'm thinking I might do a manual lift with pneumatic struts. I know @rayra has mentioned using conduit. I like the idea of being able to use threaded connectors but bolting and wrapping the circular conduit seems challenging.

This is where I currently am in my thought process and would love any feedback!

Step 1: 1/2" or 3/4" Plywood (or maybe deck composite since it won't rot)

- Lay two verticals and a few cross supports.

- Reinforce corners with dowels.

- Wood is definitely easier for me to work with. My only concern is a lot of people have been talking about wood rot in fiberglass, but that's mostly on boat forms and I guess I'm not too worried out here in dry Colorado.

Step 2: Lay final 3 layers of glass to seal that in

Step 3: Square tube or "c" channel frame.

- This will not be glassed in.

- Canvas can screw to inner edges.

- Pneumatic lift can attach to bottom edge (I hope)

Step 4: Add a couple more supports since the frame will be lifting the top

Step 5: Pull from mold, flip, add two strips of stainless steel to to the top to reinforce where the rack will sit, and glass that in

- Rack would either:

1. Bolt all the way through (this makes me nervous because of having to seal it)

2. Attach weld nuts to the top and use them to bolt to the rack (would still run some carriage bolts all the way through the stainless steel strips to make sure they are secure, but would glass over them to seal it in)

I'm hoping to do pneumatic struts similar to the build @DAlgozine posted. Anyone know where to get some like this? I'm hoping to lift about 4 feet and am guessing that means I need some that are about 5 feet extended?

Any other thoughts or advice would be greatly appreciated! Biggest concerns right now are:

1. Wood rot.

2. Sealing any holes I drill through.

3. Finding struts that will lift the top ~4 feet.

TL;DR It's moving forward