SONICMASD

Adventurer

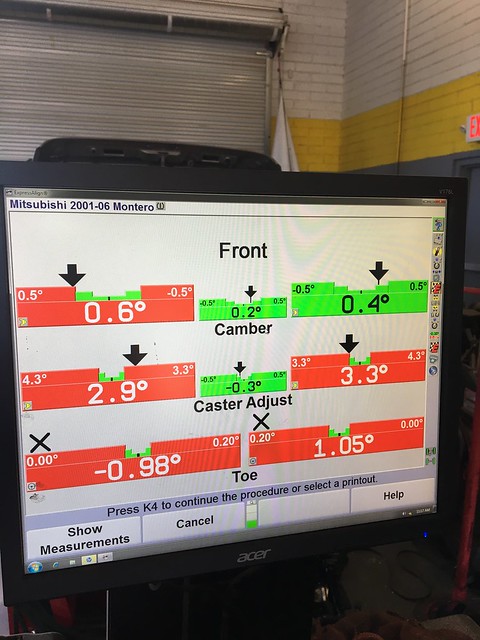

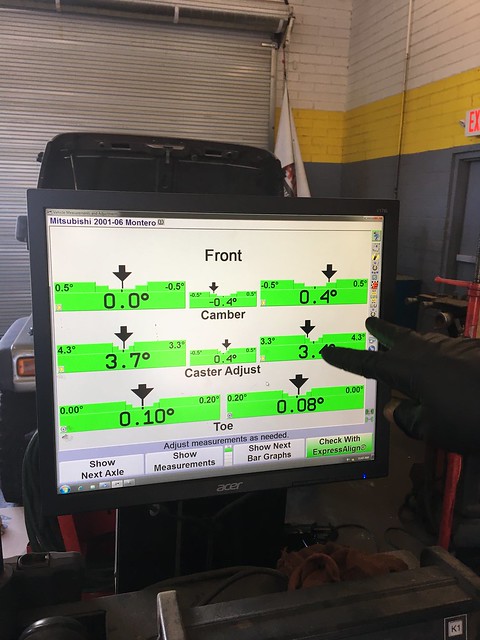

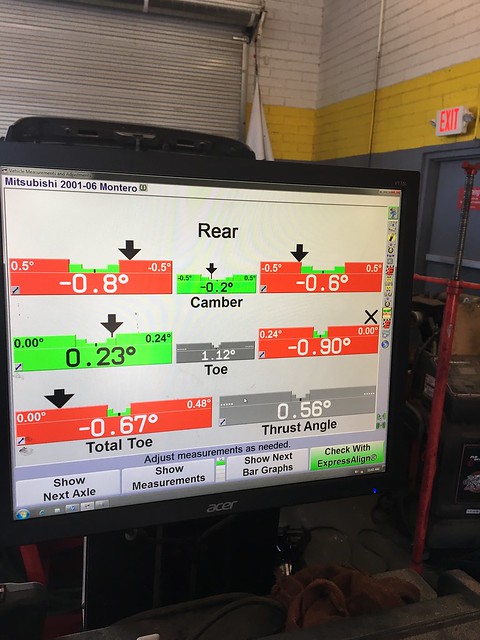

10/7/18: Front Suspension Update - One of the things that was apparent this vehicle needed during my test drive was an alignment since the steering wheel was about 20 degrees off center. So I took it in for an alignment but the shop said there was no point in aligning it because the front suspension had worn out parts - Upper Control Arm Bushings, Outer Tie Rod Ends, and Inner Tie Rod Ends.

Ernest had just replaced the Driver Side ITRE and both boots so I really only needed one ITRE.

Shopping List:

Mitsubishi Upper Ball Joint x 2

Mitsubishi Inner Tie Rod End

Mitsubishi Inner Tie Rod End Boot Band Clamp

Mitsubishi Outer Tie Rod End x 2

Siberian Front Upper Control Arm Bushing Set x 2

Now, you might be wondering - why not just order the pre-built Mitsu UCAs with ball joints and bushings already installed? This is definitely the way to go because pressing out bushings is a huge PITA and worth avoiding whenever possible. BUT, speaking with Toasty, he tells me that he recently bought new complete Mitsu UCAs for his 98 and within a few months the bushings tore. He suspects that although they were indeed New, they were probably old stock that was manufactured many many years ago and had been sitting in a hot warehouse somewhere. So not wanting to risk that, I went with Siberians.

You also might be wondering why not use Moog or any other aftermarket brand that is much cheaper than OEM - Because I've seen Moog's quality go way down over the years and I only want to do this job once. I know the Mitsu parts are expensive but Suspension/Steering is on a fully independent suspension vehicle that I use to fly down corrugations is not something I wanted to skimp on.

Removing the components is very easy and straightforward on the Gen3. I used a 3# sledge to break the OTREs and UBJs free from the knuckle but if you live in a rusty environment you may want to invest in Harbor Freights ball joint tool which would make short work of it as well.

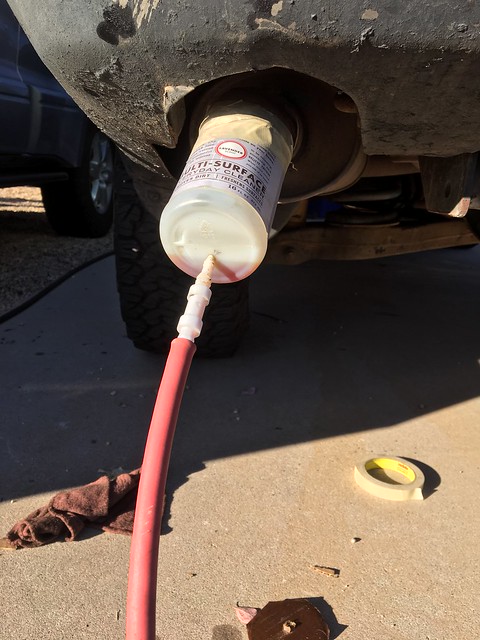

You'll also want to borrow an ITRE tool from your local autoparts store for this

IMG_2245

IMG_2245

The hardest part about removing the UCAs is getting a socket onto the 22mm nut and bolt since there is not a lot of room to work with because of the coil springs. I used a crescent wrench on one end and a deep wall socket with 26" breaker bar on the other end and soaked the bolts in homemade penetrating fluid (acetone + atf) the day before.

Here is everything apart:

IMG_2217

IMG_2217

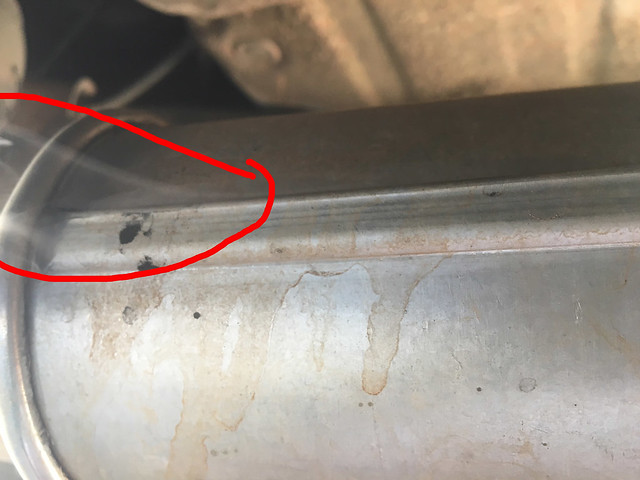

Inside the passenger side ITRE hole there was some debris from the old unit. I cleaned it up before installing the new one.

IMG_2244

IMG_2244

The UBJs just unbolt from the UCA so the only hard part of the disassembly process is getting the bushings out. Ernest and I made an attempt at pressing them out with a 20ton press but didn't choose a good socket size and ruined the passenger side UCA. Word of advice, don't push on the rubber part of the bushing hoping it will remove the metal case, it won't. It will just deform the entire control arm. That silver cylinder you see sticking out of the arm is the socket, it's in there good and not going anywhere now.

IMG_2524

IMG_2524

IMG_2523

IMG_2523

IMG_2528

IMG_2528

IMG_2527

IMG_2527

So lucky for me I knew of a guy parting out a 2001 so I went over there and removed another UCA. But the good news is this one came off an AZ truck with 25,000 less miles and has zero rust. The original UCAs have a little light rust on them from their time in UT and WA.

Ok, so not wanting to attempt the bushing removal again I dropped the UCAs and Siberian Bushings off at a local auto repair shop. The owner said he would get them done in a day or two.

In the meantime, just for fun and research, I doused the messed up UCA in gasoline and made a half-assed attempt at burning out the bushings.

IMG_2231

IMG_2231

Conclusion - a torch is necessary and you don't want to breathe this stuff in so my recommendation is don't do it. You would still need to punch out the metal bushing case and it will be covered in gooey gross rubber ashy stuff so it's not worth it.

Ernest had just replaced the Driver Side ITRE and both boots so I really only needed one ITRE.

Shopping List:

Mitsubishi Upper Ball Joint x 2

Mitsubishi Inner Tie Rod End

Mitsubishi Inner Tie Rod End Boot Band Clamp

Mitsubishi Outer Tie Rod End x 2

Siberian Front Upper Control Arm Bushing Set x 2

Now, you might be wondering - why not just order the pre-built Mitsu UCAs with ball joints and bushings already installed? This is definitely the way to go because pressing out bushings is a huge PITA and worth avoiding whenever possible. BUT, speaking with Toasty, he tells me that he recently bought new complete Mitsu UCAs for his 98 and within a few months the bushings tore. He suspects that although they were indeed New, they were probably old stock that was manufactured many many years ago and had been sitting in a hot warehouse somewhere. So not wanting to risk that, I went with Siberians.

You also might be wondering why not use Moog or any other aftermarket brand that is much cheaper than OEM - Because I've seen Moog's quality go way down over the years and I only want to do this job once. I know the Mitsu parts are expensive but Suspension/Steering is on a fully independent suspension vehicle that I use to fly down corrugations is not something I wanted to skimp on.

Removing the components is very easy and straightforward on the Gen3. I used a 3# sledge to break the OTREs and UBJs free from the knuckle but if you live in a rusty environment you may want to invest in Harbor Freights ball joint tool which would make short work of it as well.

You'll also want to borrow an ITRE tool from your local autoparts store for this

IMG_2245

IMG_2245The hardest part about removing the UCAs is getting a socket onto the 22mm nut and bolt since there is not a lot of room to work with because of the coil springs. I used a crescent wrench on one end and a deep wall socket with 26" breaker bar on the other end and soaked the bolts in homemade penetrating fluid (acetone + atf) the day before.

Here is everything apart:

IMG_2217

IMG_2217Inside the passenger side ITRE hole there was some debris from the old unit. I cleaned it up before installing the new one.

IMG_2244

IMG_2244The UBJs just unbolt from the UCA so the only hard part of the disassembly process is getting the bushings out. Ernest and I made an attempt at pressing them out with a 20ton press but didn't choose a good socket size and ruined the passenger side UCA. Word of advice, don't push on the rubber part of the bushing hoping it will remove the metal case, it won't. It will just deform the entire control arm. That silver cylinder you see sticking out of the arm is the socket, it's in there good and not going anywhere now.

IMG_2524

IMG_2524 IMG_2523

IMG_2523 IMG_2528

IMG_2528 IMG_2527

IMG_2527So lucky for me I knew of a guy parting out a 2001 so I went over there and removed another UCA. But the good news is this one came off an AZ truck with 25,000 less miles and has zero rust. The original UCAs have a little light rust on them from their time in UT and WA.

Ok, so not wanting to attempt the bushing removal again I dropped the UCAs and Siberian Bushings off at a local auto repair shop. The owner said he would get them done in a day or two.

In the meantime, just for fun and research, I doused the messed up UCA in gasoline and made a half-assed attempt at burning out the bushings.

IMG_2231

IMG_2231Conclusion - a torch is necessary and you don't want to breathe this stuff in so my recommendation is don't do it. You would still need to punch out the metal bushing case and it will be covered in gooey gross rubber ashy stuff so it's not worth it.

IMG_2494

IMG_2494 IMG_2499

IMG_2499 IMG_2500

IMG_2500 IMG_2522

IMG_2522 IMG_2530

IMG_2530 IMG_2531

IMG_2531 IMG_2532

IMG_2532 IMG_2540

IMG_2540 IMG_2541

IMG_2541 IMG_2543

IMG_2543 IMG_2544

IMG_2544 IMG_2547

IMG_2547 IMG_2582

IMG_2582 IMG_2583

IMG_2583 IMG_2584

IMG_2584 IMG_2587

IMG_2587 IMG_2589

IMG_2589 IMG_2591

IMG_2591 IMG_2629

IMG_2629 IMG_2574

IMG_2574 IMG_2578

IMG_2578 IMG_2570

IMG_2570 IMG_2580

IMG_2580 IMG_2581

IMG_2581 GYUT1138

GYUT1138 ROEM5340

ROEM5340 IMG_0858

IMG_0858 IMG_0869

IMG_0869 IMG_0875

IMG_0875 IMG_0916

IMG_0916 glasspack

glasspack IMG_1359

IMG_1359 IMG_1382

IMG_1382 IMG_1379

IMG_1379 IMG_1377

IMG_1377 IMG_1314

IMG_1314 IMG_2681

IMG_2681 IMG_2833

IMG_2833 IMG_2801

IMG_2801 IMG_2803

IMG_2803 IMG_2820

IMG_2820 IMG_2808

IMG_2808 IMG_2811

IMG_2811 IMG_2814

IMG_2814 IMG_2817

IMG_2817 IMG_3649

IMG_3649 IMG_2863

IMG_2863 IMG_2862

IMG_2862 IMG_2865

IMG_2865 IMG_2867

IMG_2867 IMG_2859

IMG_2859 IMG_2866

IMG_2866 IMG_2889

IMG_2889 IMG_3202

IMG_3202