So, 35's are heavy. The brakes on the 1st Gen Tundra, are, in a word, OK. Since my truck is a 06, I already have the 13WL calipers, the larger caliper/rotor combo that alot of Tacoma and pre 04 Tundra owners upgrade to.

As much as Id' like to do the StopTech BBK upgrade, at $2000ish, I can think of alot of other places that money could be more effectively used.

I have no idea what pads/rotors are on the truck at the moment, but the thicknesses are good and I am not gonna change parts just for the sake of changing parts. The rear drums I did about a year ago, changed the shoes, drums and hardware kit, everything but the brake cylinders.

Everyone with a 1st Gen Tundra knows how much of a PITA it is to get the star adjusters just perfect. Lightly dragging on the drum, but not too much. Once click to far and your pulling the drum off to reset them. I've dinked around with them before and got it to where I was happy. I also did a full bleed of the brake system to get some new DOT 3 fluid in. That helped with pedal feel and brake fade and would recommend it to anyone.

However, I still feel there's a bit left in the brakes that I can squeek out.

The LSPV/BV, or Load Sensing Proportioning Valve / Bypass Valve, is a system that I think was invented with the best intentions in mind, however, in my eyes, always seemed kinda of gimicky.

The LSPV/BV, for those that don't know, looks like this. (Not my Tundra)

It has two jobs. One, when you put weight in the bed, the distance between the bed and axle decreases causing the angle of that metal rod to change, which in turn will open up a valve in the LSPV/BV, allowing more fluid to flow to the rear wheel cylinders, increasing the brake bias from front to rear and giving you more rear braking power. It has three brake fluid lines. An inlet feed like that comes from the ABS module, a return line that doubles back and hooks back up into a T fitting under the brake booster and the axle/wheel cylinder line that feeds your rear drums.

Sounds awesome! However, when you start lifting vehicles, changing around leaf springs and other stuff, the valve wont do its job properly. Also, over time, it will get jammed up and rusty as things always do, and wont't move as freely. The guy before me that put the lifting blocks under the leafs also put a bracket on the axle end of the rod to relocate it up 3 inches. This relocation bracket, or piece of flat bar with 4 holes in it, is sold as the best way to "to keep the geometry" the same. But ya, I question it....

The second job of the LSPV/BV, is the second part of the name, the Bypass Valve. Since the LSPV is allowing different amounts of fluid/pressure to go through to the rear wheel cylinders, the fluid that is not needed on the rear brakes is "Bypassed" and sent back to engine bay and into the front brake loop.

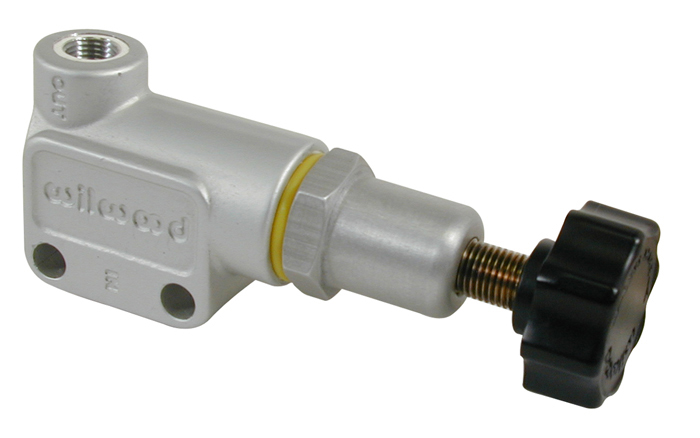

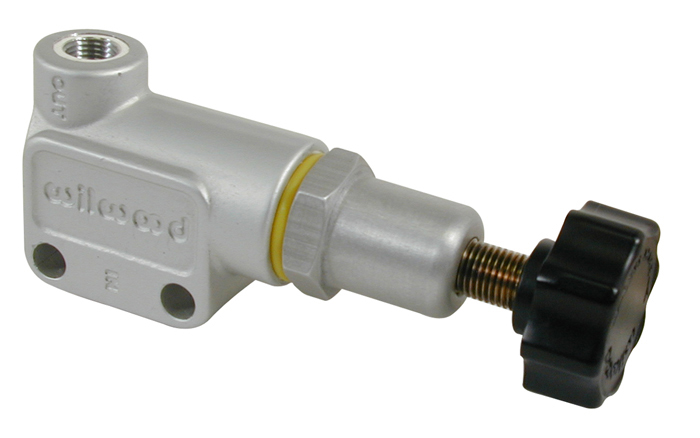

So, how to go about removing the LSPV/BV? A common solution to this problem is to install a manual brake proportioning valve, and, we can go about this two ways.

Option 1) A valve like this , Willwood 260-12627 , $50. Single Inlet and Single Outlet. But you say, Scott! I have 3 lines going to my LSPV, and that only has two! How can we make it work? Well, easy enough. In your engine bay, under your brake MC, by the brake booster, is a T fitting. This is where the return line fitting comes back into, and feeds the front brake loop. If you pop this off, plug it with a 10MMx1 fitting, you've isolated that line and now have a simple two line setup with no return. Then hook the OEM Toyota into the Inlet and the Axle/Wheel Cylinder line to the Outlet, and there ya go.

Option 2) A valve like this , Wilwood , 260-11179, $90. Made for front and rear brakes. The rear circuit has a single inlet and single outlet with the adjustable proportioning valve. The front circuit has a single inlet with two outlets. It can be run as a single outlet with one outlet plugged, or used to split the plumbing on its way to the front calipers. This one is a bit nicer, and comes with a brake light switch you don't need, but you can take that off and plug it.

To use this one, you can plug the Rear Input and Rear Output ports. Run the OEM Toyota Input line into "Front Input", run the OEM Toyota Return Line into the "Front Outlet" and then hookup the line going to the rear axle/wheel cylinders from the Front Outlet. This way, you don't have to deal with capping off the T fitting in the engine bay, however, since Toyota uses 10MMx1 fittings, and this is 3/8-24, there will be some creative use of adapters aswell as some re-flaring of lines to switch them from bubble to inverted flare.

Both have some advantages and disadvantages. I guess this is me thinking out loud. Maybe someone will find this useful.

Another reason for this, is that sometime in the future, after the shackle flip kit/new leaf pack, I'll be cutting the rear tire carrier out, bracing the frame with some 2in DOM and making some custom behind the axle shock mounts to stuff in a 2.5x10 KING smoothie w/ reservoir.