PacificNorthWestJeeper

Blissfully Lost

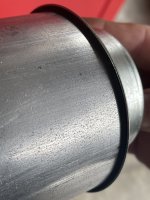

The rear Kelderman install begins. This is where I am currently at:

- I read a couple articles (on the web) about Kelderman's powder coating not being the greatest, who knows right? Either way, as a precautionary measure I sprayed 3 coats of clear onto all Kelderman bracketry for good measure. Maybe it will help the powder coat hold up, maybe it won't.. Either way I feel better sssoooo........

- Frame bracketry installed

- Axle bracketry hand tightened into place.

- 1 airbag per side in, waiting to install the track bar & sway bar before I install the 2nd airbag per side and then torque down the axle bracketry.

I should be able to wrap up the rear in one more day....

.

.

- I read a couple articles (on the web) about Kelderman's powder coating not being the greatest, who knows right? Either way, as a precautionary measure I sprayed 3 coats of clear onto all Kelderman bracketry for good measure. Maybe it will help the powder coat hold up, maybe it won't.. Either way I feel better sssoooo........

- Frame bracketry installed

- Axle bracketry hand tightened into place.

- 1 airbag per side in, waiting to install the track bar & sway bar before I install the 2nd airbag per side and then torque down the axle bracketry.

I should be able to wrap up the rear in one more day....

.

.

Last edited: