Hi All,

Happy Thanksgiving! I’m a day late, maybe two, but who’s counting

.

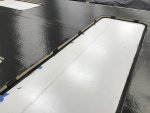

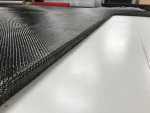

While you were baking a turkey, I was baking my roof panel ?.

It’s crazy to think that it has been a month since my last post. That thing called LIFE happened again and I lost two full weeks on the build. I’m glad to be back on the project and grinding away ?

.

I’ll pick up where I left off……….

The resin finally showed up, but a week and a half later than quoted. I love it when you pay out the wazoo for shipping and they can’t even get it to you within the conservative time estimates they give you.

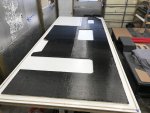

I finalized the roof layout and created the vent fan, AC unit and skylight cut out templates while waiting for the resin. I also checked/laid out the angles, clearances, aesthetics and wind flow of the cab over roof angle to the skylight spoiler and skylight.

I'll get into more info, details and pics when it is finalized, but I also did some modifications to the A/C unit while creating the cut out template for the roof panel. This 12V A/C unit is one of the most efficient, quietest, lightest and lowest height profiles for its BTUH rating and the price point is almost half the cost of other comparable 12V rooftop units, $2,500 vs $4,500-5,000. This is all GREAT as Mabru got its start in the marine A/C industry and is looking to enter the RV A/C market. BUT, the problem is they still have to refine their design of the installation of this unit and the supply/return grill assembly is big and ugly. They want you to cut SIX separate holes in the roof (supply/return opening, electrical penetration, and four mounting holes) to install this thing, as opposed to having everything come through one 14 x 14 opening like many other rooftop A/C unit manufactures.

I'm going to do custom supply registers in the ceiling headliner and run a common return ceiling (I won't have a visible return grill), so I didn't care about the ugly supply/return grill-I was going to toss it anyway. As far as the six penetrations in the roof, I knew I could re-route the electrical through the supply/return opening and I was hoping I could remount the four main mounting bolts to also come through the supply/return penetration. Unfortunately, I could not remount the four main mounting bolts to sit inside the supply/return opening, so I will have have to drill four holes for the mounting bolts. Not a huge deal, as their gasket takes care of all of this, but the less penetrations the better.

I also decided to do two smaller cutouts in the roof for the supply and return, as opposed to one larger cutout. This left more material, therefor structural support, in my roof and will also make it easier to create/install a custom foam boot that will be needed to separate the supply air from the return air in the head liner/common return ceiling. (You will see a picture of this in the roof panel layup post to come.)

The other quirky thing is the plastic baseplate for the unit sticks out further than the top cover, so I cut it back and shaped it to match the lid. I spoke with the MFG's RV A/C department about all of these modifications and they said they know, they're considering them for the next model.

These were all little modifications I was willing to do/tolerate given this things specs and price point.