You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

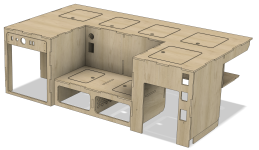

2024 RAM CCLB flatbed + Overland Adventure Truck composite shell build thread

- Thread starter janders

- Start date

Pacific Northwest yetti

Expedition Medic

Looking great!

janders

Active member

Wow! You have some mad freakin's wood skills!!! Looking great!

Thanks! Maybe a more apt statement would be that my CNC machine has some mad wood skills.

ExpoMike

Well-known member

You're not in the SoCal area are you? I have some work for your CNC machine.Thanks! Maybe a more apt statement would be that my CNC machine has some mad wood skills.

janders

Active member

You're not in the SoCal area are you? I have some work for your CNC machine.

'Fraid not. We're posted up in the PNW. If you can swing it and have room for it, a CNC machine is a game changer. I'd do a hell of a lot less woodworking if I didn't have it.

janders

Active member

I have some interior updates but the inside is a bit of mid-project train wreck. So I'll update y'all on some outside stuff, specifically the awning.

When we camp, we live under our awning. We're in the PNW so it's either raining or too damned sunny. Having an easily deployable awning is key. However, mounting an awning on the side of a camper with walls made out of foam isn't a recipe for success. When you deploy free-standing awning arms, they put a big torsional load on whatever you mount them to and fiberglass-sandwiched foam isn't going to handle that. So we had to figure out what on the camper had enough structural integrity to handle a big ol' 270deg awning.

Turns out the jack plates used to mount jacks to lift the camper on and off the truck are very structural. So we took some 1/4" aluminum angle iron and combined it with a 2"x6"x1/8" aluminum box beam to run an awning mount between the two jack plates. Then we mount the awning directly to that box beam and Bob's your uncle. Freestanding awning hanging off the side of the camper.

Fabricating the mount in the shop

Dry-fit before welds

Dry-fit after welding up the pieces

Prepping the awning for install on the mount

Success!

Deployed

I'm a little concerned with how much it sticks out from the side of the camper when we're driving. That's something we'll have to pay attention to and see if it causes problems. But sitting under that massive awning drinking a beer was pretty relaxing...

When we camp, we live under our awning. We're in the PNW so it's either raining or too damned sunny. Having an easily deployable awning is key. However, mounting an awning on the side of a camper with walls made out of foam isn't a recipe for success. When you deploy free-standing awning arms, they put a big torsional load on whatever you mount them to and fiberglass-sandwiched foam isn't going to handle that. So we had to figure out what on the camper had enough structural integrity to handle a big ol' 270deg awning.

Turns out the jack plates used to mount jacks to lift the camper on and off the truck are very structural. So we took some 1/4" aluminum angle iron and combined it with a 2"x6"x1/8" aluminum box beam to run an awning mount between the two jack plates. Then we mount the awning directly to that box beam and Bob's your uncle. Freestanding awning hanging off the side of the camper.

Fabricating the mount in the shop

Dry-fit before welds

Dry-fit after welding up the pieces

Prepping the awning for install on the mount

Success!

Deployed

I'm a little concerned with how much it sticks out from the side of the camper when we're driving. That's something we'll have to pay attention to and see if it causes problems. But sitting under that massive awning drinking a beer was pretty relaxing...

Last edited:

janders

Active member

Spencer for Hire

Active member

Very nice! I wish I had 1% of you and your wife's skills. Are you putting in an ac or just 1 or 2 fans? Thank You.

Similar threads

- Replies

- 0

- Views

- 977

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 513

- Replies

- 18

- Views

- 3K