You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-4 Link Suspension?

- Thread starter Section 8

- Start date

GeoTracker90

Adventurer

Are you proposing to eleminate the leaf springs and use links to locate the axle tube and use air bags to spring it with?

Personally I would think that a true independent suspension w/ airbag, like the ones that Adventure Trailers uses, would be a better solution for the same or even less amount of work. They do have a retrofit kit available for some trailers.

Just my thoughts. What do you think?

Personally I would think that a true independent suspension w/ airbag, like the ones that Adventure Trailers uses, would be a better solution for the same or even less amount of work. They do have a retrofit kit available for some trailers.

Just my thoughts. What do you think?

Section 8

Observer

Well, I do think that it would be significently easier to build a linked suspension vs the independent. I do want to differentiate between "easy" and "ammount of work" though; they mean different things to me.

I think you are 100% correct.

However, after reading the independent suspension thread, I think that giving up the advantages of being independent for the ease of construction also makes sense. I don't "need" IS, but I do need the ability to vary the capacity of the trailer, which airbags do well.

The more I fart around, I realize that I am just slowly spiraling into getting the retrofit. The farther you get into doing your own, if you don't have anything to work off of, the cost doesn't strike you as much.

I think you are 100% correct.

However, after reading the independent suspension thread, I think that giving up the advantages of being independent for the ease of construction also makes sense. I don't "need" IS, but I do need the ability to vary the capacity of the trailer, which airbags do well.

The more I fart around, I realize that I am just slowly spiraling into getting the retrofit. The farther you get into doing your own, if you don't have anything to work off of, the cost doesn't strike you as much.

Last edited:

Rezarf <><

Explorer

I think a 3 or 4 link setup is killer on the trucks we drive, where we have to axles to contend with the terrain. However, on a single axle trailer the articulation that a 3-4 link provides isn't always what is best.

I would have to agree, this is one of the areas that an Indy suspension shines, especially since the movement is more vertical than rotational. You can have the trailer adjust per side, verses the entire axle needing move on both sides.

Clear as mud?

I'd like to see one, that is for sure!

Rezarf <><

I would have to agree, this is one of the areas that an Indy suspension shines, especially since the movement is more vertical than rotational. You can have the trailer adjust per side, verses the entire axle needing move on both sides.

Clear as mud?

I'd like to see one, that is for sure!

Rezarf <><

Section 8

Observer

The articulation is by product of the soft spring rate and the leverage from the other axle. When the trailer is free to rotate about the hitch, it isn't going to articulate, much less need to. Because of this, there isn't going to be 4 foot links, and 14" shocks. I am thinking more along the lines of a road car, like the Fox body mustangs.

RHINO

Expedition Leader

if your using a solid axle why bother with 3 or 4 link at all? how about a simple arm suspension on each side like the old chevy fleetside trucks with the coil springs. i can already see it, mount the arm with u-bolts to the axle like leaves and the other end to a spring hanger, throw the airbag on top, in front, or behind the axle and you got it.

Funrover

Expedition Leader

Yeah I was going to do something similar for awhile. I was going to set it up like a rover. I was going to get a rear axle from a RRC like mine (so I will ave extra parts if needed hehehehe) and mount it up like my truck. 2 trailing arms, an a- arm to keep the axle centerend, springs and shocks. It seems like it would provide a very nice smooth ride on/off the road. And with the aig bags the adjustability would be great to have. I am still considering it, the biggest problem I have found is air bags in the right size.

ntsqd

Heretic Car Camper

I can see the appeal in going to air springs, but with a live axle on linkage you really aren't gaining what ITS (Independent Trailer Suspension) will gain you. If the sole reason for linkage on a live axle is to gain the use of air springs why not use only the main leaf of a leaf spring coupled with an air spring? Saves designing & fabricating one-off parts that may or may not need iteration to a successful solution. All off the shelf wear parts is a good thing.

I'll venture that if you need spare parts off the trailer to keep the tow rig functional that you're really not Overlanding, you're on an extended rock crawl. Not that an extended rock crawl is bad, but that it isn't what I understand the emphasis to be here.

I'll venture that if you need spare parts off the trailer to keep the tow rig functional that you're really not Overlanding, you're on an extended rock crawl. Not that an extended rock crawl is bad, but that it isn't what I understand the emphasis to be here.

GeoTracker90

Adventurer

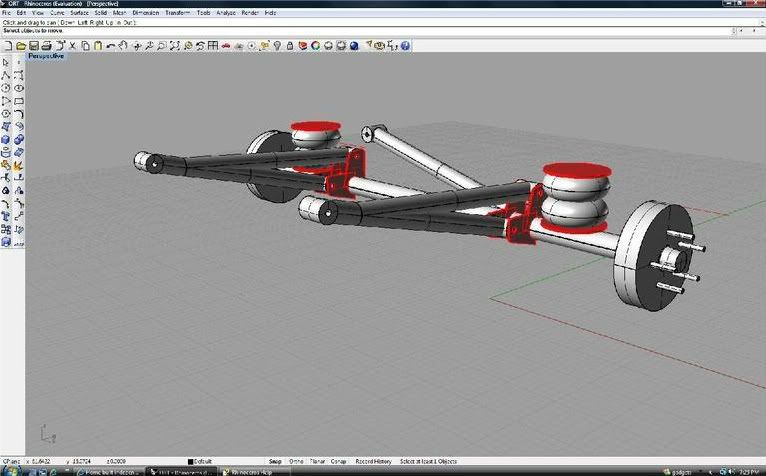

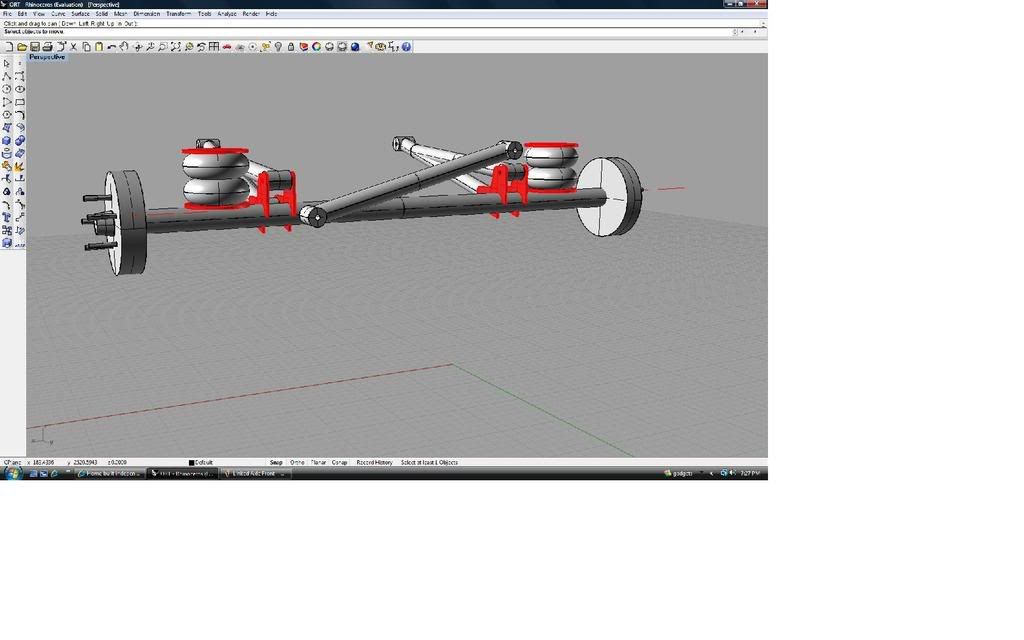

Ok, I played with this idea and came up with....

Last edited:

Section 8

Observer

ntsqd said:I can see the appeal in going to air springs, but with a live axle on linkage you really aren't gaining what ITS (Independent Trailer Suspension) will gain you. If the sole reason for linkage on a live axle is to gain the use of air springs why not use only the main leaf of a leaf spring coupled with an air spring? Saves designing & fabricating one-off parts that may or may not need iteration to a successful solution. All off the shelf wear parts is a good thing.

UGH! Its not about duplicating independent suspension, is about eliminating the negatives of torsion axles and leaves, which is slightly overloading your trailer for week long treks, or having a trailer that has very little suspension the rest of the time if you plan for the maximum load.

As for parts, there are ALOT of 4x4 places that cater to those building suspensions for rock crawlers and trail trucks. That is not the problem.

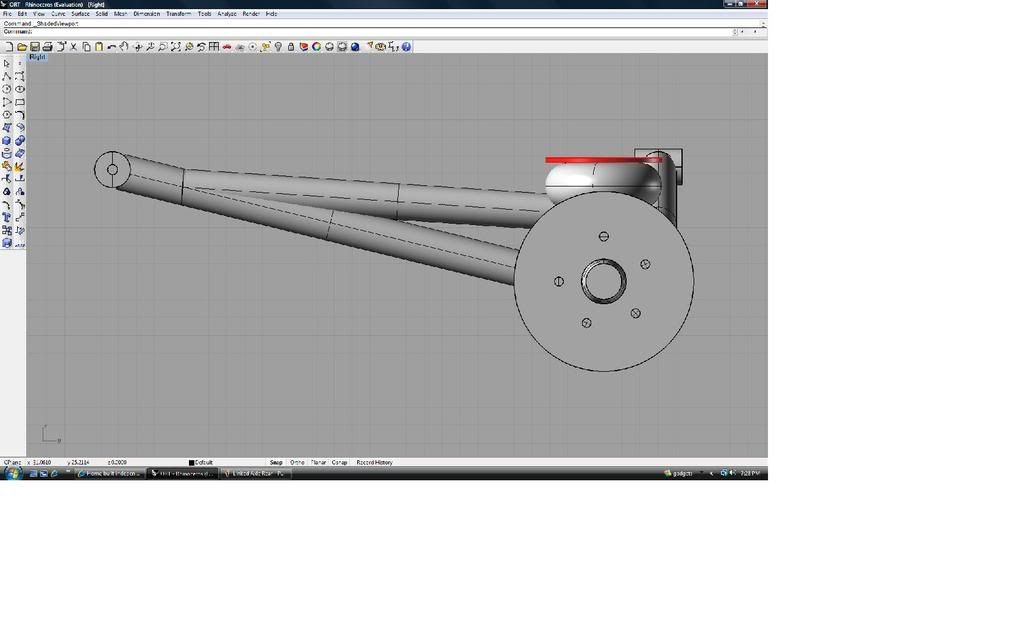

That design is very good. I still draw with a pencil but I am learning Pro-e. Speaking for myslef, I don't know that I could fabricate that design though. I don't think my tube notcher will notch that wide of an angle. With that in mind, I WOULD duplicate that with square tube.

ExpoMike

Well-known member

TheGillz said:Man that looks killer, but I might be missing something but I don't see how it would articulate? If the right goes up, how does the left go down with how those arms attach to the axle?

The rotational part of the axle works from bushing deflection. If you look at your JK, your axles "should" only move up and down but if you jack one side up, look at the bushing at the pivot points, they are deflecting within the rubber to allow everything to twist. This is why you don't want urethane bushings for an offroad rig, they are too stiff and don't allow the deflection. Great for a race car.

A really good way would be to use "Johnny Joints" or heim joints for the pivot locations but they transmit a lot more vibration and noise into the chassis.

Hope that helps a little.

ntsqd

Heretic Car Camper

What I was thinking in terms of. Much simpler to execute using far more off the shelf parts that can be found at most any trailer supply house or parts house. Wouldn't be ITS, but that didn't sound like it was a goal. Using only the main leaf keeps the base spring rate low. Were it an off road race car this would create a damping nightmare, but for a trailer it shouldn't be a problem.

A long cope like above is difficult to produce. Most fabricators put a bend in the converging tube so that the cope angle isn't so shallow. If you flop the whole arm over that will buy the room needed for the bend at the expense of some clearance.

Alternately stub a piece at 90* and dive the converging tube into it rather than the main tube. Cap the stub.

A long cope like above is difficult to produce. Most fabricators put a bend in the converging tube so that the cope angle isn't so shallow. If you flop the whole arm over that will buy the room needed for the bend at the expense of some clearance.

Alternately stub a piece at 90* and dive the converging tube into it rather than the main tube. Cap the stub.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 13

- Views

- 5K