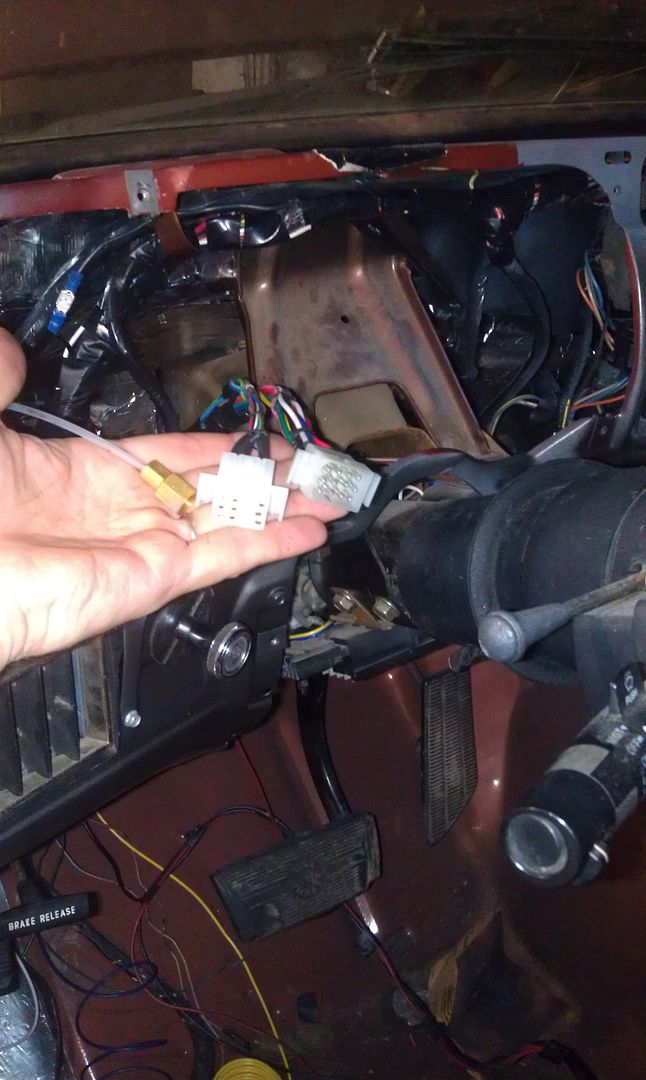

Got the truck side of the dash all wired up and connectors in place......well at least down to the firewall. Still need to run the other side of the firewall for the oil, water, and speedo signal wires but that is easy. Gonna start putting the dash back together tomorrow and then finish off the bezel and install the gages for the last time.

Two connectors and a vaccuum line

Quick and easy when I am ready to install the cluster.

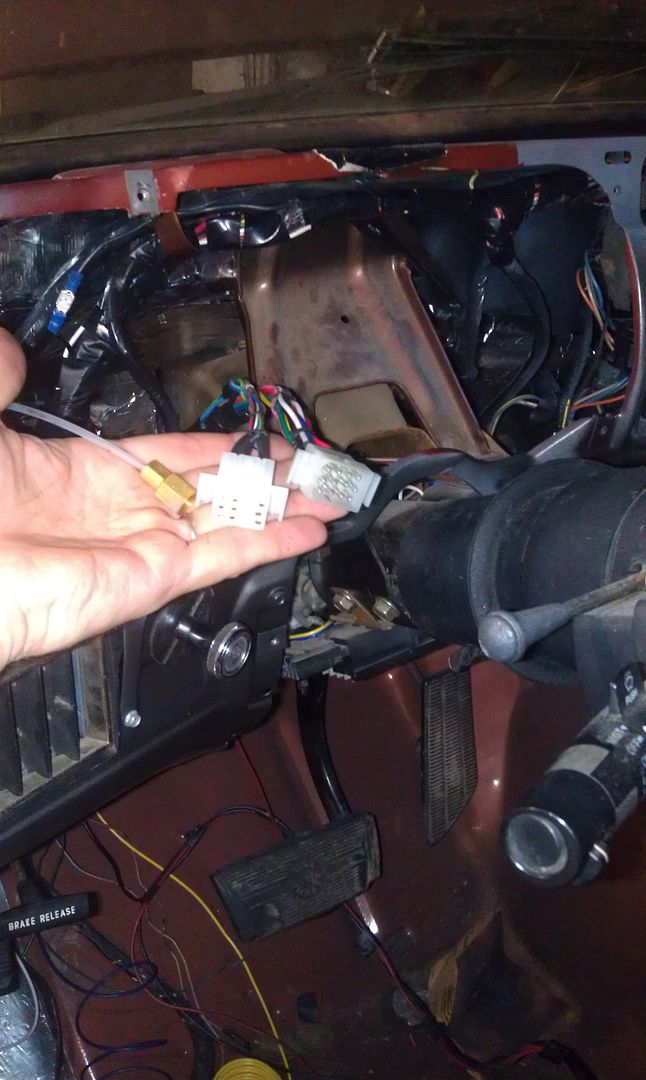

Two connectors and a vaccuum line

Quick and easy when I am ready to install the cluster.