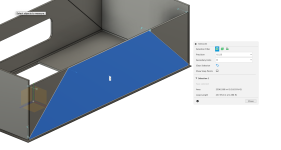

Was finally able to get some time to start working on the roof and get it connected to the folding walls. I'm happy to report that it folds and opens!

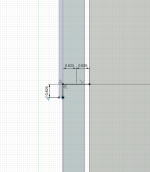

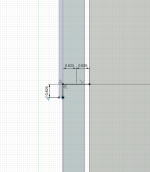

The most difficult part to getting this right is determining the length and positioning of the double hinges that connect the roof to the walls. My calculations in my cad program indicated that the hinges should be half the distance from the side wall to the front/back wall below the centerline of the front/back wall. Because that is a complicated description, here is a drawing:

That being said, it didn't really work out that way in real life (still not sure why) and ended up being closer to the center of the front/back walls. In the end I just kept opening and closing the roof and walls and kept measuring to find the point at which the hinge was the same length when it was opened as it was when it was closed.

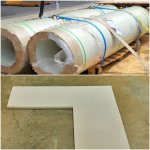

As for the hinges I ended up cutting some leftover aluminum piano hinges I used for the side walls into 2" strips. Then I plug welded those hinges to some 2"x1/8" aluminum strips I cut to length. I was a little worried that the aluminum hinges might not be strong enough, but they seem to be plenty sturdy at the moment— only time will tell.

Next up I will need to figure out where I'm going to attach my gas struts and what amount of force they will need. The easiest way I could think to do this would be to put a crane scale on the roof section, crank it up, and read the weight. Luckily I had a fairly sturdy crane system in my garage that I formerly used to hang some kayaks. But first I was curious what the overall weight of the popup section might be, so I cranked it up until the whole frame was lifted off the ground.

The weight of the whole unit came out to 183 lbs. I think we could easily call it an even 200-220 lbs by the time the roof gets covered and insulated plus windows, hardware, etc. At first glance I was a little surprised at the weight, but then I started comparing it to the other options I've considered in the past.

Depending on the size, the AluCab ModCap tent is in the 308-359 lbs range (excluding mattress and canvas, no bedding), so I'm at least 100 lbs lighter or more.

Hiatus publishes a weight of 460-490 lbs for their mid-size truck camper. If you add the weight of my popup section plus the weight of my ModCap canopy at 176 lb, we end up with 376-396 lbs total for the unit.

In both cases I'm quite a bit lighter than the alternatives I explored in the past, so even if I do end up underestimating the additional weight that will be added by the time it's done, I think it's likely I won't be any heavier than those alternatives.

So now that I had a rough weight of the entire unit, I looked at the maximum weight required to lift the roof and wall sections.

This came out to a force needed to lift 84 lbs— let's call it an even 100 by the time the roof is covered. I'm smart enough to know that because of the direction the force is being applied and the non-linear nature of force in gas struts at different lengths, that I can't just take 100 lbs and divide it by 4. But that's about as far as my smarts go. I will likely have to leverage a calculator for gas struts as well as a lot of trial and error in mounting positions to get it right. Maybe someone with some specific knowledge can offer some advice here?

Because my frame is so low-profile, I don't really have a good way to attach struts without welding a bracket to it, so the ability for trial and error in the strut mounting positions is going be extremely difficult— I'm going to need to get creative.

It's funny because about 3 days ago I got so frustrated with the lack of some sort of t-slot mechanism in my frame, for adjustments and hardware mounting, etc., that I nearly decided to throw everything out and start over from scratch with a design based on 80/20 extrusions. But calmer heads prevailed and I realized it wasn't quite worth wasting the $1000+ I've spent on materials (at least yet). Which brings up another interesting tidbit— why didn't I start by designing the frame around off the shelf t-slot extruded aluminum like many other people do? The main reason I chose not to was primarily based on shipping costs. My frame is almost 10' long, and I didn't want to compromise strength by joining two pieces of 5' t-slot, so I really needed to order 10' lengths. Many of you may know that shipping anything over 6' in length generally adds astronomical costs because it usually means it has to be shipped via LTL (less-than-truckload) freight. So in the end I just couldn't stomach paying $1,000 in shipping for $1,000 worth of materials, so the idea was abandoned. But then I discovered something a few days ago— my local Grainger store will sell 10' lengths of t-slot extruded aluminum! The material costs are higher than most places online (typical Grainger), but because there are no shipping costs, the overall cost is MUCH more reasonable.

Anyway, I'm still committed to this design not only because it's nearing completion, but also because I think it will likely end up being much lighter than the t-slot. But now I have a possible option for a version 2.0 (if I ever get the courage to do it again).

Hopefully the next update will be a video of it opening and closing (with the assistance of gas struts) on it's own!