deminimis

Explorer

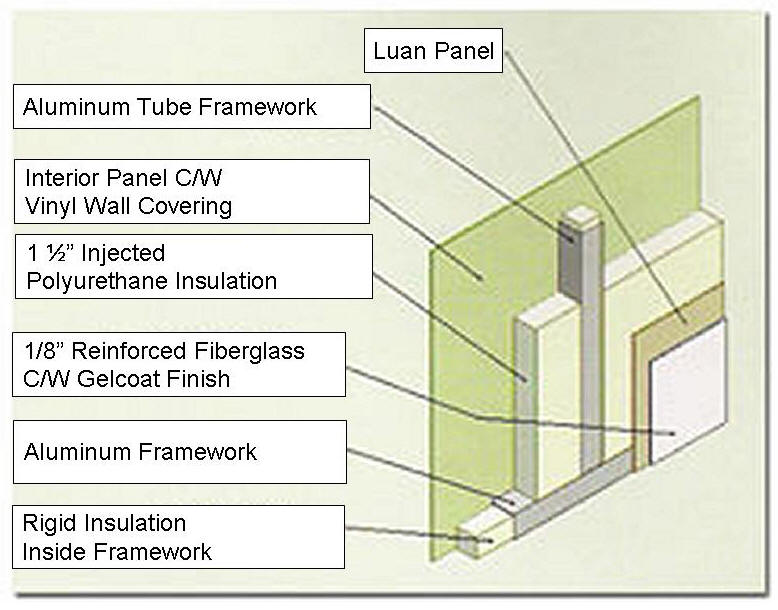

Has anyone looked at the interior wall construction of a Bigfoot truck camper? I'm needing to install/build a drop down upper bunk bed in our 2500 series camper and I'm wondering if there are studs in the wall to tie into. Hate to pull the skin to see, but guessing that's my only option (unless someone has already been down this road). Specifically, I'm looking at the area around the dinette. Here's the plan: