teotwaki

Excelsior!

After my initial install ( http://www.expeditionportal.com/forum/showthread.php?t=36900 ) of the ARB/3rd member in my 4Runner all seemed fine. Recently I was out wheeling and noticed that if I had any articulation of the rear axle that the pressurized air was somehow venting into the axle and then coming out of the axle's vent cap. The vent cap is remoted on a rubber line up to the area near my gas cap.

As shown in the install pictures, there is no way that the blue air line or brass fitting on the outside are moving when the axle articulates.

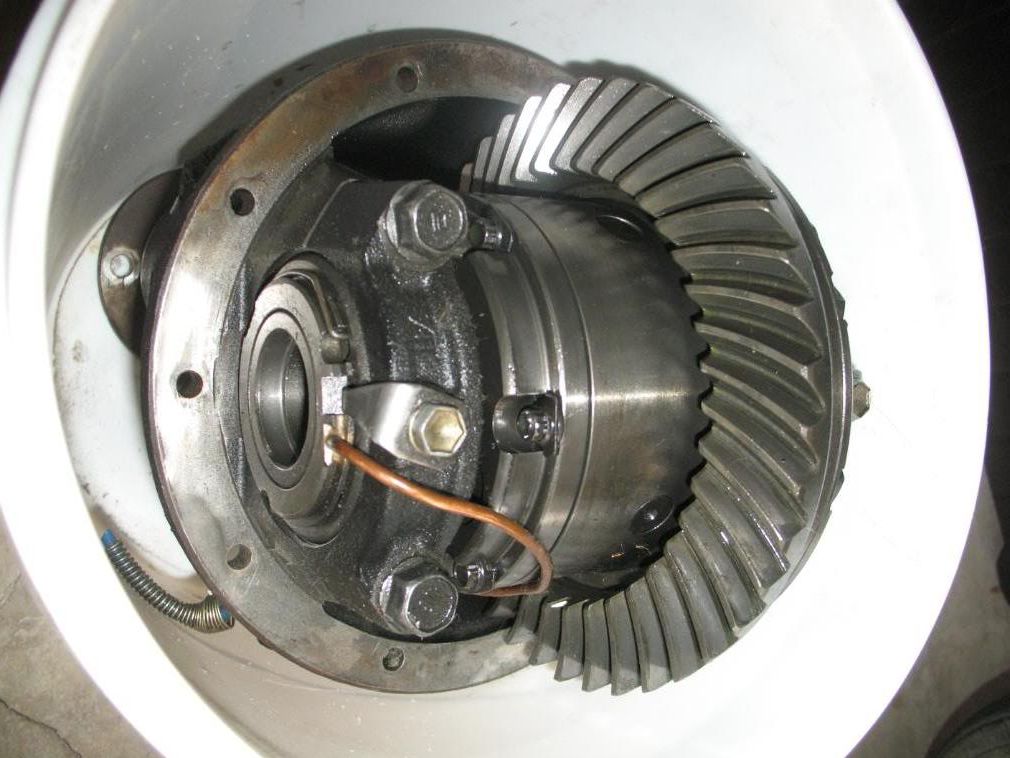

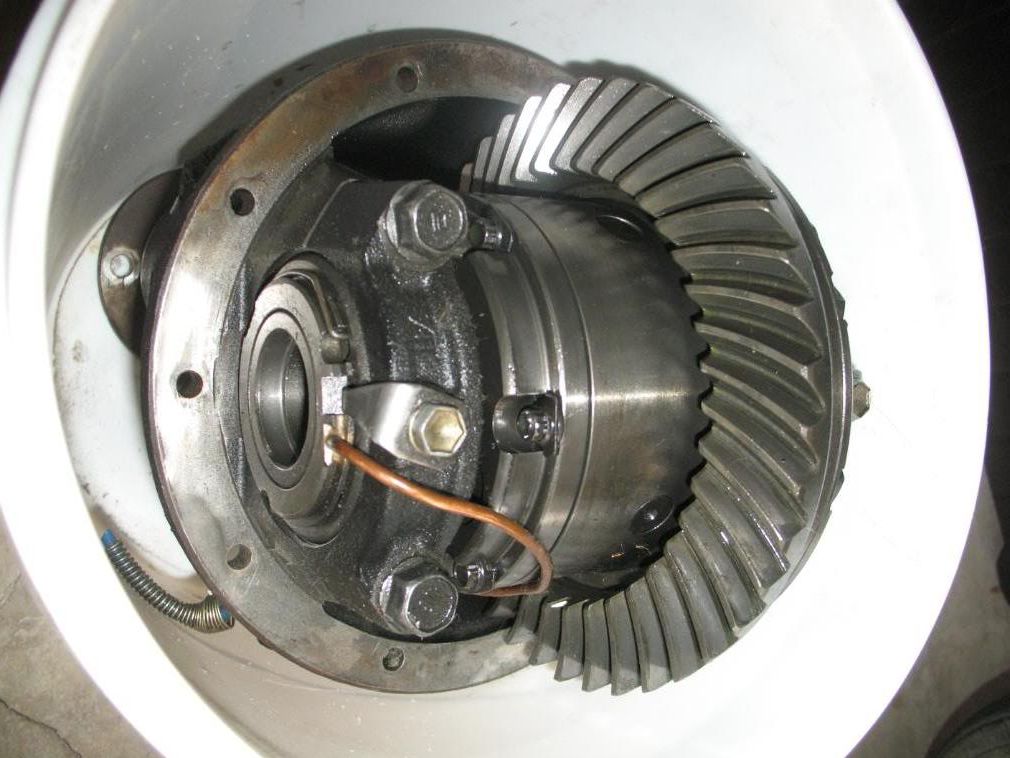

All I can guess is that somehow the screw-in fitting that holds the internal copper air line has come loose from the brass fitting screwed onto the outside of the third member housing. (found this picture on the web. Not mine)

From the outside the fitting seems tight.

I still cannot see how the air flow is affected only when the axle is articulated. I would think that it would always be venting.

Is there that much movement of the copperline if there is heavy torque on the ARB?

I am okay with disassembling the brass fitting but am afraid that if the copper line "pulls" back into the housing I'd have to pull the third member to grab the line and pull it back up into the threaded hole in the housing.

As shown in the install pictures, there is no way that the blue air line or brass fitting on the outside are moving when the axle articulates.

All I can guess is that somehow the screw-in fitting that holds the internal copper air line has come loose from the brass fitting screwed onto the outside of the third member housing. (found this picture on the web. Not mine)

From the outside the fitting seems tight.

I still cannot see how the air flow is affected only when the axle is articulated. I would think that it would always be venting.

Is there that much movement of the copperline if there is heavy torque on the ARB?

I am okay with disassembling the brass fitting but am afraid that if the copper line "pulls" back into the housing I'd have to pull the third member to grab the line and pull it back up into the threaded hole in the housing.