teotwaki

Excelsior!

If you can't find the o-rings give me holler, I've got baggies of them.

Thank you very much!

If you can't find the o-rings give me holler, I've got baggies of them.

What a hassle! Imagine if this was happening out in the bush.

What a hassle! Imagine if this was happening out in the bush.

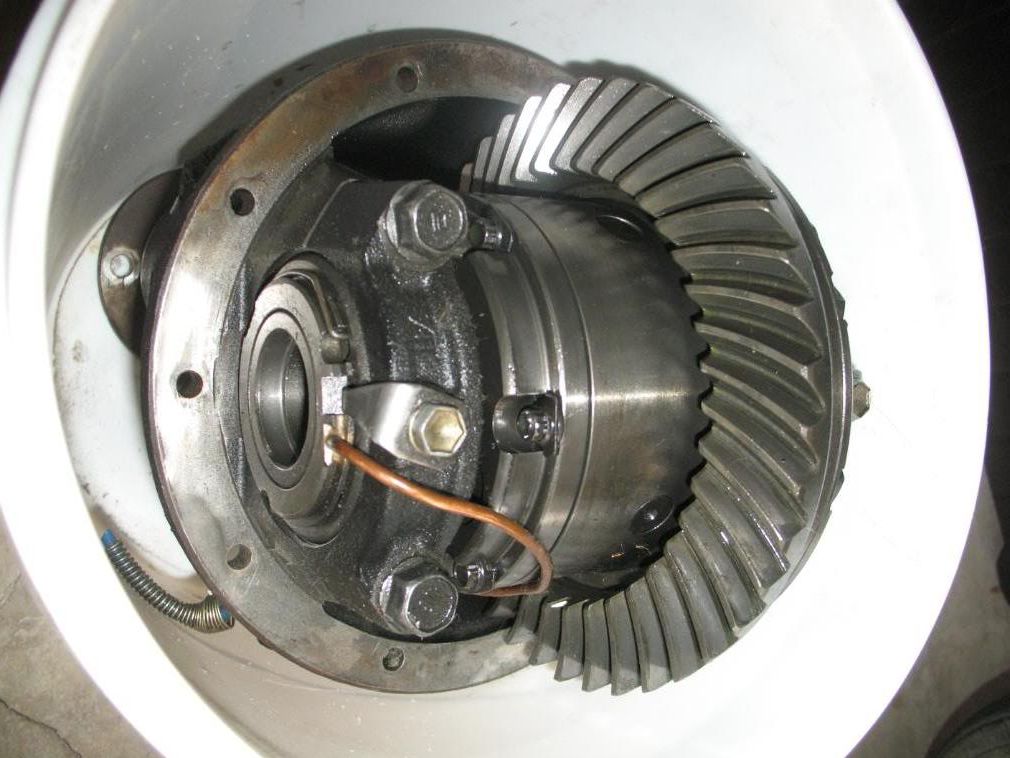

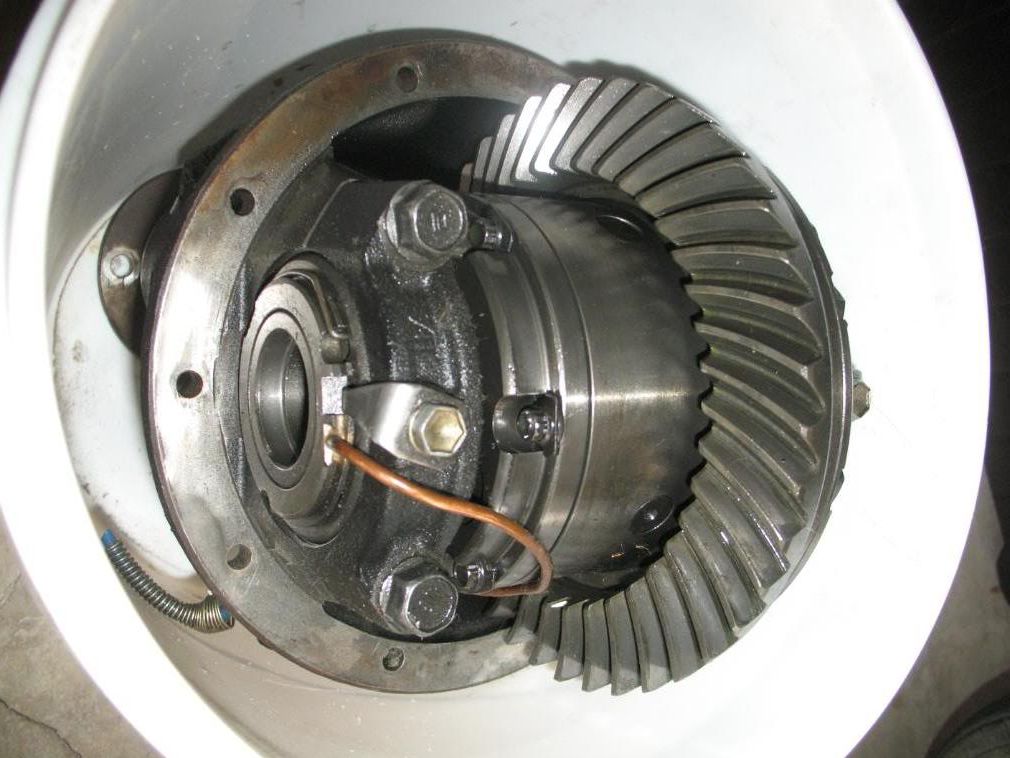

...What I plan to do is get the new O-ring in there and then see if I still have any problems. One of my guesses is that the old O-ring in the bulkhead fitting was sealing just enough to hold pressure but that any movement of the copper line let air leak by and into the housing.

I too hope that is the case, the bulkhead o-ring is cheap and easy to fix, seal housings rings are not :smilies27

Some other tech thoughts you might find helpful here:

http://www.cruiseroutfitters.com/tech_ARB_troubleshoot.html

Cool, glad you got it figured out.

We'll have to have another go at the hill up to the salt tram to see how you do with working locker. Should be much easier.

So, Timkens are a no go for sure? These are the bearings mentioned by ECGS for their assembled clamshells w/ARB lockers. I know of another place that specs Timken as well. If I have found a low miles diff w/ARB locker for sale I should skip it since it is confirmed to most likely not have not been built with OEM bearings (most likely Timken)? Who is actually building clamshells w/lockers and OEM bearings?