I installed one of the preproduction door hinges today so I could finalize a design for mounting a step.

The mounting hardware worked out very easily; it's just a mounting plate, a nut plate that slides inside the hinge, and a few bolts and nuts. The bolts I used wouldn't be the final choice if these went into production, they're just what I had handy. I haven't painted the mounting plate yet, it's still raw steel.

The step performed just fine in the 225-lb. gorilla test.

One thing I like about this design vs. the other door hinge steps on the market is that you don't have to remove the hinge bolts to install/remove the step - the step installs to the hinge without loosening the door hinge bolts, so it's a lot easier to install/remove. It's quick to install, so I might only have the steps on the Jeep when I've got the rack on the top, and I'd remove the steps when I remove the rack.

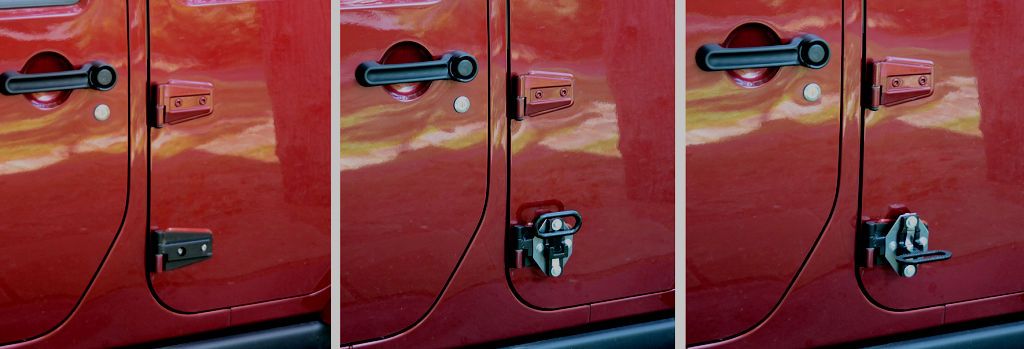

I did some research on the other hinge-mount steps on the market, and with some help from Donny discovered that all of the other steps on the market interfere with the front door when they're hinged down and the rear door is open:

The way this step mounts directly to the bottom hinge, it doesn't interfere:

On the other hand, this step is lower than the Kargo Master step on Donny's Jeep because that step mounts on a bar between the two hinges.

So now some design decisions... the step mounted to the lower hinge is lower than the Kargo Master step; I don't know how big a deal that would be. But a second step could be mounted on the upper hinge, which would allow for climbing higher than the Kargo Master single step. BTW a step on the upper hinge would interfere with the driver's door when the back door was open, just like the Kargo Master interferes. A step on the bottom hinge never interferes.

I could add a bar like the Kargo Master and mount the steps to the bar, and there could be several mounting locations on the bar for one or two steps, but that would add cost - as it is I spent about $11 for the step itself (paid retail), and the mounting bracket is a simple laser-cut piece of steel so it would be very inexpensive.

I welcome your thoughts on this.