jscherb

Expedition Leader

I like your 5L Jerry can mount. I use that size to carry premixed chain saw gas.

You show the mount on the MORryde hinge on your LJ. Thanks, that gives me a reason to take on another project.

If you don’t mind, what gage metal did you use to bend up your prototype.

I’ve never carried the 5L on my Jeep because if I’m using the chain saw and need that much gas, I’m driving the truck in order to haul what we cut.

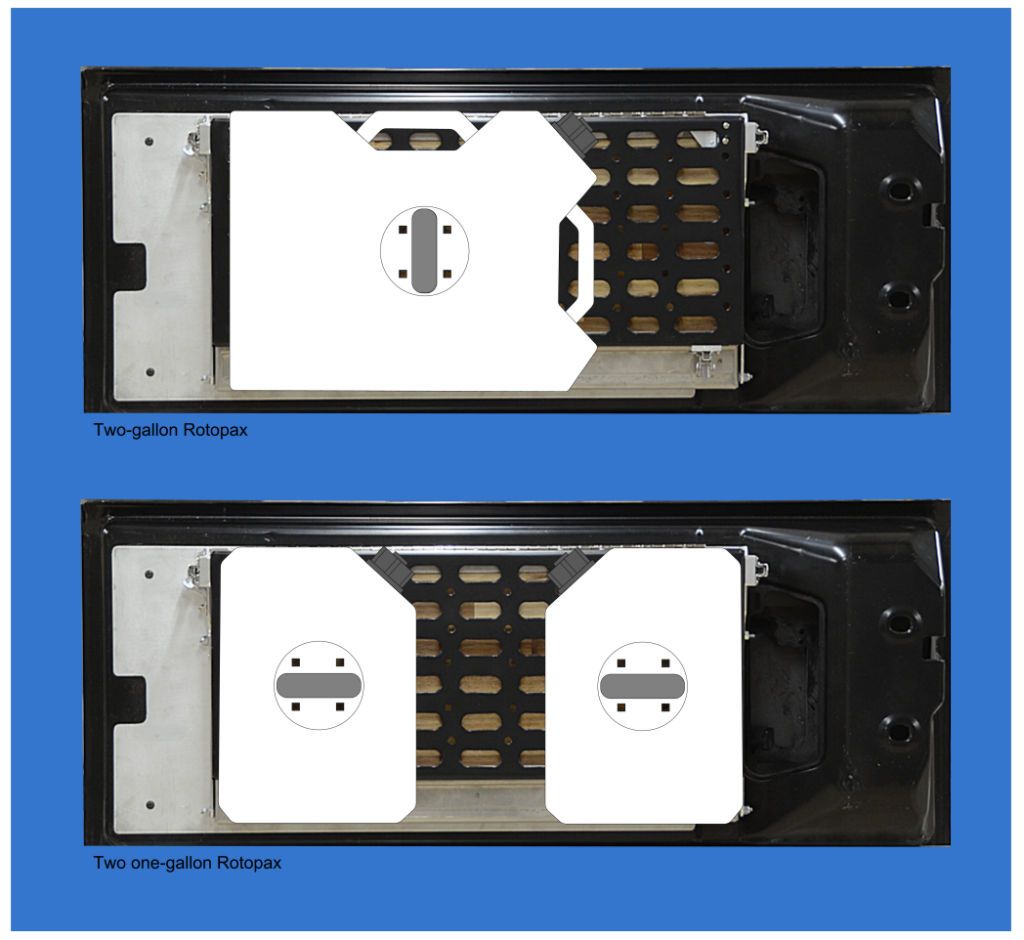

Because I was using scrap left over from other projects, I made it in two pieces. The back is 14-gauge steel and the tray is 16-gauge steel.