Back when I was working on the slider window kits for JK/JKU factory hardtops and now that I'm working on cargo window/hatch kits for the JK/JKU/JL/JLU I've gotten a lot of requests from people for similar kits for the TJ. I did a slider window kit design for the TJ a while back and more recently I did a design for a cargo hatch kit.

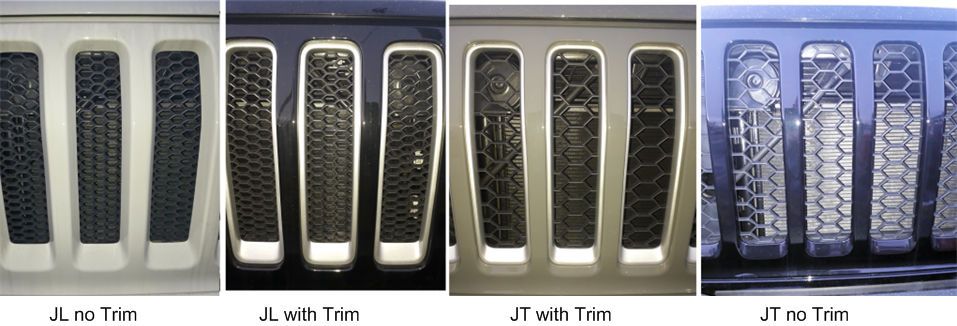

In all Wranglers, the factory hardtop windows are compound curved - they curve vertically and horizontally. This means a standard RV-style window or hatch can't be directly installed once the factory glass is removed. Because of the way the glass sets in a recess in the JK/JL hardtops, the retrofit kit to provide a flat mounting surface for the slider window or hatch is fairly straightforward but because of the way factory windows are mounted on the TJ hardtop, a retrofit kit for the TJ is a lot more complicated (and expensive).

Here's a concept image showing what a TJ slider kit would look like. The retrofit kit would replace the factory window; it would be bonded in place the same way the factory window is and would have the same plastic trim around the perimeter that the factory glass does. The kit would be a non-trivial shape; it would match the compound curves of the TJ factory glass around the edges and provide a flat mounting surface for the slider window. Based on the tooling investment to produce the retrofit kit and the cost of manufacturing the retrofit kit, I expect a complete slider window kit for both sides of the hardtop couldn't profitably retail for less than $800. I can't imagine too many TJ owners paying that much.

There are two ways a cargo hatch kit could be done - one way would be to use the same retrofit kit that the slider window would use and install a swing-up RV-style cargo window in the retrofit kit. This is exactly what I'm doing for the JK/JL cargo window kits.

Another way would be to make the hatch larger - the hatch could be the full size and compound curved shape of the factory window. It would be hinged at the top, latched at the bottom and the sealing surface would be the factory hardtop window mounting surface with appropriate weatherstrip applied. Flush latches and gas struts would be installed and it would be painted to match the hardtop. I would look like this:

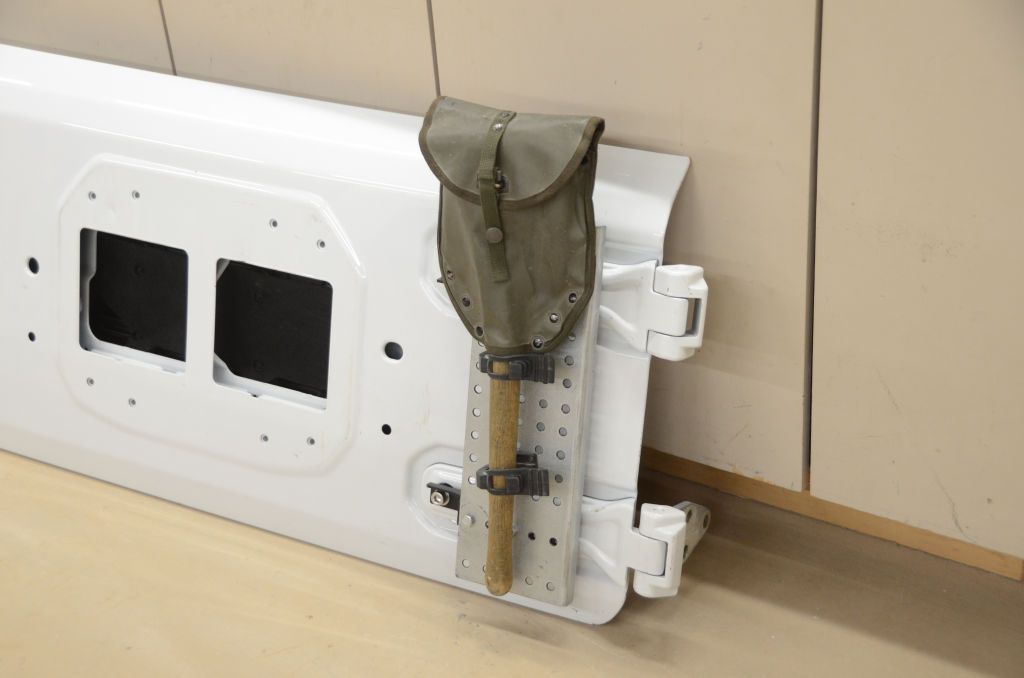

A MOLLE panel could be an option; the panel would mount to the roll bar and things could be hung on both the hatch-facing side of the panel and the inside of the panel. Open, the hatch with the MOLLE panel would look like this:

Based on the tooling cost and manufacturing cost for a TJ cargo hatch I estimate a kit couldn't be profitably sold for less than $750 each, and the MOLLE option would probably add another $200 each.

The above designs are practical and could be built, but other than doing the designs, I haven't done any work to implement either slider windows or cargo hatches for the TJ because I just don't think there would be enough demand in the TJ market to make it worthwhile to build these. If people have views to the contrary or other comments on anything above I'd be interested in what you think.