You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barn Door for JK factory hardtops

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Did you ever come up with a way to keep the OE JKU hard top and convert or replace just the back door to barn style?

Yes, that's easy, did that back in October. Back then I posted this video of Tom testing the barn door on his '14 JKU with his factory hardtop. Since that video was shot, the window was installed, the wiper and the defroster grid were installed and wired, the washer plumbing and nozzle was installed and the fiberglass was shot with gray primer and Tom's been running with the barn door ever since. He says he'll never go back to the factory two-step tailgate/hatch system

MagicMtnDan

2020 JT Rubicon Launch Edition & 2021 F350 6.7L

Look what Jeep is showing...(one of their 7 concepts)...Jeep Red Rock Responder

It's a pickup

It's a pickup

jscherb

Expedition Leader

Look what Jeep is showing...(one of their 7 concepts)...Jeep Red Rock Responder

...

It's a pickup

I thought that was a Honda Ridgeline

MagicMtnDan

2020 JT Rubicon Launch Edition & 2021 F350 6.7L

It's a pickup - a concept and it won't make it to production. But I'm sure we will see a pickup after the next gen Jeep Wrangler is released.

MagicMtnDan

2020 JT Rubicon Launch Edition & 2021 F350 6.7L

Another one of Jeep's recent concept vehicles has this...

a barn door!

This is the "Wrangler Africa"

It has steel wheels and there are a set of proven Dana 44 axles front and rear, though Jeep doesn't say anything about whether or not the sticks come with lockers. The beefier front axle is a good thing with the larger tires, and the torque from the 2.8-liter turbo-diesel engine.

The 2.8-liter mill is small and fairly lightweight, but still manages to make big torque low in the rev range, right where you need it when it comes time to scramble over an obstacle. The extra fuel economy will also help you stay out longer, as will the auxiliary fuel tanks. Win.

Add in body protection like hood-to-roof guy wires, rock rails, and a high-clearance, steel front bumper, and you're good to tackle everything but the meatiest of trails. Oh, and if you do happen to get stuck, there's a winch up front to help yank you out.

a barn door!

This is the "Wrangler Africa"

It has steel wheels and there are a set of proven Dana 44 axles front and rear, though Jeep doesn't say anything about whether or not the sticks come with lockers. The beefier front axle is a good thing with the larger tires, and the torque from the 2.8-liter turbo-diesel engine.

The 2.8-liter mill is small and fairly lightweight, but still manages to make big torque low in the rev range, right where you need it when it comes time to scramble over an obstacle. The extra fuel economy will also help you stay out longer, as will the auxiliary fuel tanks. Win.

Add in body protection like hood-to-roof guy wires, rock rails, and a high-clearance, steel front bumper, and you're good to tackle everything but the meatiest of trails. Oh, and if you do happen to get stuck, there's a winch up front to help yank you out.

MagicMtnDan

2020 JT Rubicon Launch Edition & 2021 F350 6.7L

Here are some more pics and info on the Wrangler "AFRICA" concept Jeep

It has steel wheels and there are a set of proven Dana 44 axles front and rear, though Jeep doesn't say anything about whether or not the sticks come with lockers. The beefier front axle is a good thing with the larger tires, and the torque from the 2.8-liter turbo-diesel engine.

The 2.8-liter mill is small and fairly lightweight, but still manages to make big torque low in the rev range, right where you need it when it comes time to scramble over an obstacle. The extra fuel economy will also help you stay out longer, as will the auxiliary fuel tanks. Win.

Add in body protection like hood-to-roof guy wires, rock rails, and a high-clearance, steel front bumper, and you're good to tackle everything but the meatiest of trails. Oh, and if you do happen to get stuck, there's a winch up front to help yank you out.

It has steel wheels and there are a set of proven Dana 44 axles front and rear, though Jeep doesn't say anything about whether or not the sticks come with lockers. The beefier front axle is a good thing with the larger tires, and the torque from the 2.8-liter turbo-diesel engine.

The 2.8-liter mill is small and fairly lightweight, but still manages to make big torque low in the rev range, right where you need it when it comes time to scramble over an obstacle. The extra fuel economy will also help you stay out longer, as will the auxiliary fuel tanks. Win.

Add in body protection like hood-to-roof guy wires, rock rails, and a high-clearance, steel front bumper, and you're good to tackle everything but the meatiest of trails. Oh, and if you do happen to get stuck, there's a winch up front to help yank you out.

jscherb

Expedition Leader

JK Safari Cab project update... I'm continuing work on the molds for the roof. This past week I've been working on the molds for the front part of the drip rails and the upper jambs for the doors. The parts are circled in the photo below...

For traditional hard tops the upper jambs would just be part of the main roof panel, but for the Safari Cab they're separate parts. For most Safari Cab configurations, they'd bolt to the bottom of the main roof panel, acting just as if they'd been molded as part of the roof panel. But for some configurations, they'd be installed separately.

One reason for them being separate parts is that the roof panel is also designed so that it can be configured as a flip-up camper. In that configuration, the upper jambs would stay in place while the roof hinged up, providing a place where the bottom of the canvas sides attach.

Another benefit is that the removable roof panel could be swapped for the soft roof panel, the soft panel would attach the the upper jambs and the top of the side and rear panels.

I've also been working on the mold for the part of the drip rails that accompany the parts above, and also for two parts that are needed for the soft side configuration.

For traditional hard tops the upper jambs would just be part of the main roof panel, but for the Safari Cab they're separate parts. For most Safari Cab configurations, they'd bolt to the bottom of the main roof panel, acting just as if they'd been molded as part of the roof panel. But for some configurations, they'd be installed separately.

One reason for them being separate parts is that the roof panel is also designed so that it can be configured as a flip-up camper. In that configuration, the upper jambs would stay in place while the roof hinged up, providing a place where the bottom of the canvas sides attach.

Another benefit is that the removable roof panel could be swapped for the soft roof panel, the soft panel would attach the the upper jambs and the top of the side and rear panels.

I've also been working on the mold for the part of the drip rails that accompany the parts above, and also for two parts that are needed for the soft side configuration.

jscherb

Expedition Leader

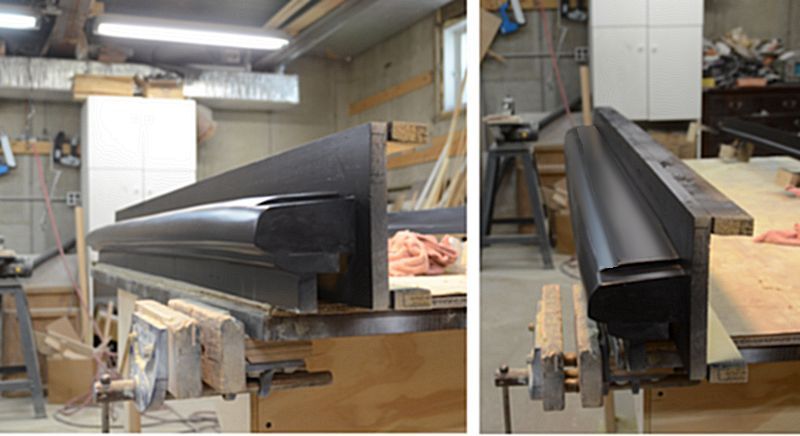

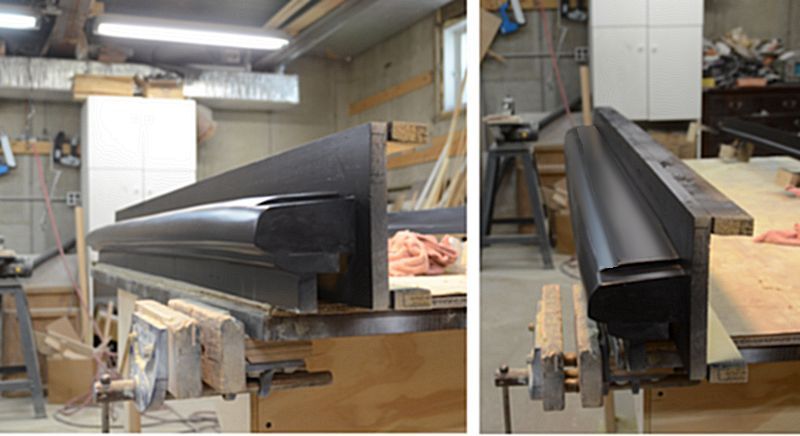

Here are a few photos of the mold master for the upper jambs that I just finished. A mold master is the master part from which a mold will be made - it's a perfect replica of what I want the final part to look like, plus a little extra that will be trimmed off after the part comes out of the mold...

If I've done my work correctly, this part will be a near-perfect replica of the factory upper door jambs and the first few inches of the top of the factory hardtop roof. There are a few differences though - for example, there's no drip rail on this part - that's a separate part that also serves as the bolt-flange to attach the roof panel, so it gets molded separately and then bonded to the underside of the roof. The drip rail mold can be seen on the back of the table in the first photo.

Another difference you might not really be able to see in these photos is that this master is "double ended" - there's a "front" on both ends. I did that because the way the curves on the hardtop work out, it's possible to mold both left and right versions of the part just by making the mold a little longer and putting "fronts" on both ends. Once out of the mold, one "front" or the other will be trimmed off to make either a left-side or a right-side part.

One final difference - at the front (both fronts ), there's a notch in the top surface. This notch allows the roof panel to sit down level with the back edge of the windshield frame. Without this, the roof panel edge would sit above the top edge of the windshield frame and wouldn't look right. This notch is also "optional", meaning that notch can be trimmed off and the part left longer on the other end by the same amount so if a full length factory profile is needed for some application, the same mold can make that part, it'll just be trimmed a little differently when it comes out of the mold.

), there's a notch in the top surface. This notch allows the roof panel to sit down level with the back edge of the windshield frame. Without this, the roof panel edge would sit above the top edge of the windshield frame and wouldn't look right. This notch is also "optional", meaning that notch can be trimmed off and the part left longer on the other end by the same amount so if a full length factory profile is needed for some application, the same mold can make that part, it'll just be trimmed a little differently when it comes out of the mold.

BTW the reason this part replicates the first few inches of the factory roof surface is that while the Safari Cab roof panel is part of the complete Safari Cab, it can also be installed on a factory roof, for perhaps building a tilt-up camper top on a factory top. So the bolt-flange surface that attaches the roof to the rest of the Safari cab parts also matches the shapes and profile of the factory hardtop, enabling the roof to be installed on a factory hardtop just as well as it can be installed on the rest of the Safari Cab parts.

The next step is to make a mold from this master, and then make the parts in that mold.

If I've done my work correctly, this part will be a near-perfect replica of the factory upper door jambs and the first few inches of the top of the factory hardtop roof. There are a few differences though - for example, there's no drip rail on this part - that's a separate part that also serves as the bolt-flange to attach the roof panel, so it gets molded separately and then bonded to the underside of the roof. The drip rail mold can be seen on the back of the table in the first photo.

Another difference you might not really be able to see in these photos is that this master is "double ended" - there's a "front" on both ends. I did that because the way the curves on the hardtop work out, it's possible to mold both left and right versions of the part just by making the mold a little longer and putting "fronts" on both ends. Once out of the mold, one "front" or the other will be trimmed off to make either a left-side or a right-side part.

One final difference - at the front (both fronts

BTW the reason this part replicates the first few inches of the factory roof surface is that while the Safari Cab roof panel is part of the complete Safari Cab, it can also be installed on a factory roof, for perhaps building a tilt-up camper top on a factory top. So the bolt-flange surface that attaches the roof to the rest of the Safari cab parts also matches the shapes and profile of the factory hardtop, enabling the roof to be installed on a factory hardtop just as well as it can be installed on the rest of the Safari Cab parts.

The next step is to make a mold from this master, and then make the parts in that mold.

Last edited:

Comanche Scott

Expedition Leader

BTW the reason this part replicates the first few inches of the factory roof surface is that while the Safari Cab roof panel is part of the complete Safari Cab, it can also be installed on a factory roof, for perhaps building a tilt-up camper top on a factory top. So the bolt-flange surface that attaches the roof to the rest of the Safari cab parts also matches the shapes and profile of the factory hardtop, enabling the roof can be installed on a factory hardtop just as well as it can be installed on the rest of the Safari Cab parts.

That idea is brilliant! Great thinking Jeff! :beer:

jscherb

Expedition Leader

That idea is brilliant! Great thinking Jeff! :beer:

Thanks. I think there are a lot of possibilities for the Safari Cab roof panel installed on a factory hardtop, so I'm trying to account for lots of options in my design - doing a tilt-up camper on top of a factory hardtop is just one of them. Another one, I can't recall if I've posted this before, is that you could modify the factory roof to have a large opening in it (maybe call it a "freedom opening"?

- Modified factory hardtop, freedom panels off and "freedom opening" cover off:

- Modified factory hardtop, "freedom opening" cover on:

- Safari Cab roof covering everything for the winter. The factory freedom panels wouldn't be installed under the roof; the jambs I posted photos of a few minutes ago would go over the doors and be bolted to the bottom of the roof.

I'm not sure if that's an idea that would appeal to anyone, but the way I've designed the panels and the interfaces between them, it would be very easy to do.

jscherb

Expedition Leader

Another pair of molds I worked up this past week are the ones for the rear door surround, which is used with the roll-up soft side panels. The soft panels need somewhere to attach to at the back of the door, and the door needs a jamb surface to seal against, so these parts are narrow pieces that serve both purposes. The rear surround is in this concept drawing, just barely visible as a narrow gray line just behind the door.

A comparison shot of the LJ Safari Cab on the trail with the soft sides rolled up:

With the soft sides rolled down:

A comparison shot of the LJ Safari Cab on the trail with the soft sides rolled up:

With the soft sides rolled down:

Jurfie

Adventurer

Me likey.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 2

- Views

- 2K

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 2K