harrisonrmatt

Member

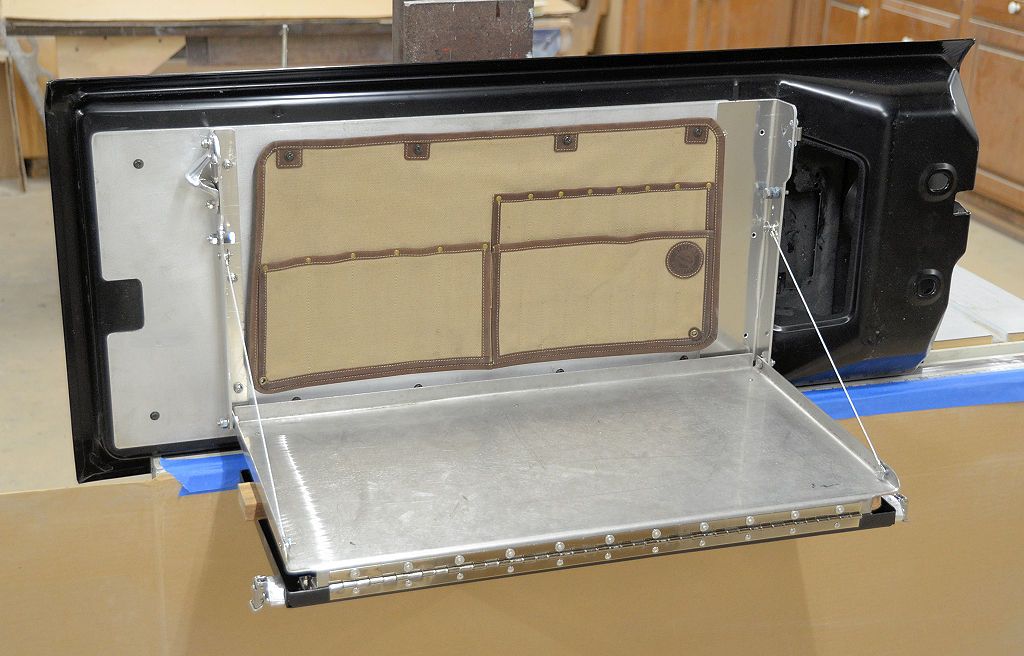

Some progress photos... this week I've been working on the mold master for the outer skin of the barn door; it's basically complete, in these photos it's just been shot with high-build primer.

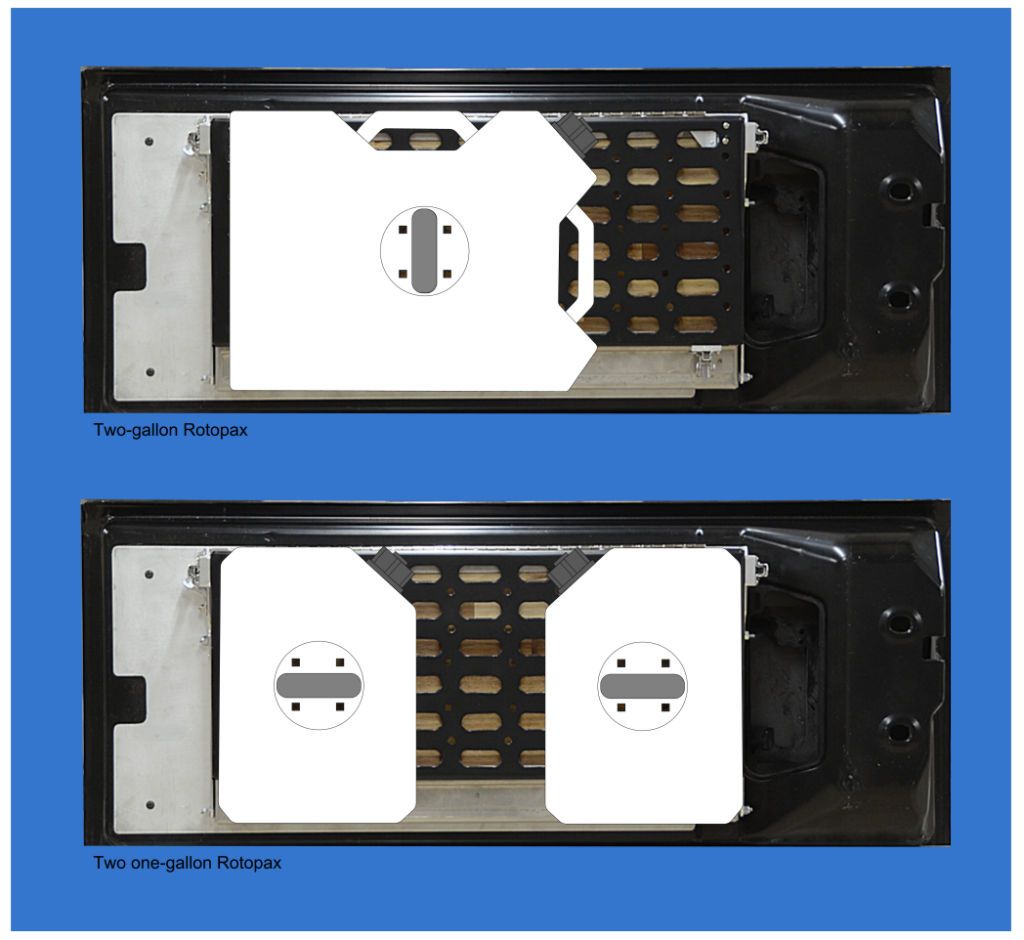

The master is curved to exactly match the curves of the hatch glass. It's several inches larger in both directions than the later model hatch glass, that's so the parts get molded oversize and then trimmed to exact size for either the late model wide hatch hardtops or the early model narrow hatch hardtops.

Hi Jeff - question for you. I am looking make a fiberglass copy of the rear hatch glass. I have all of the hardware removed from the glass (it's bare) and I have my materials... my question is, did you line the glass with something (rows of tape, parchment paper, plastic sheeting, etc.) before you proceeded? I anticipate I will want to line it before I apply Partall #2 wax, then #10 PVA, then gelcoat.

I appreciate any tips - thanks!