Metcalf

Expedition Leader

Time to mess with something new!

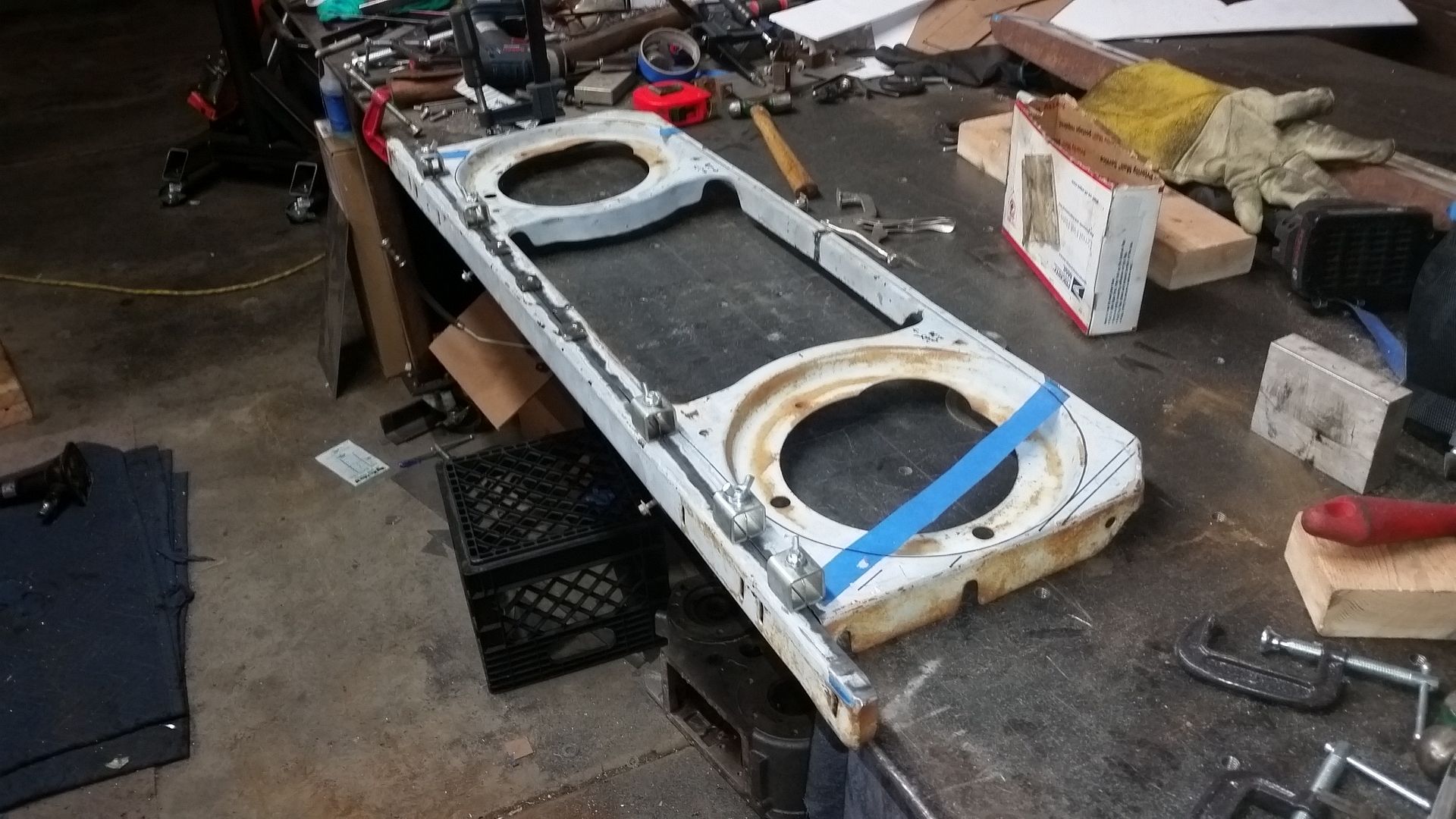

I am going to need to remake the shape of the grill.....why not....

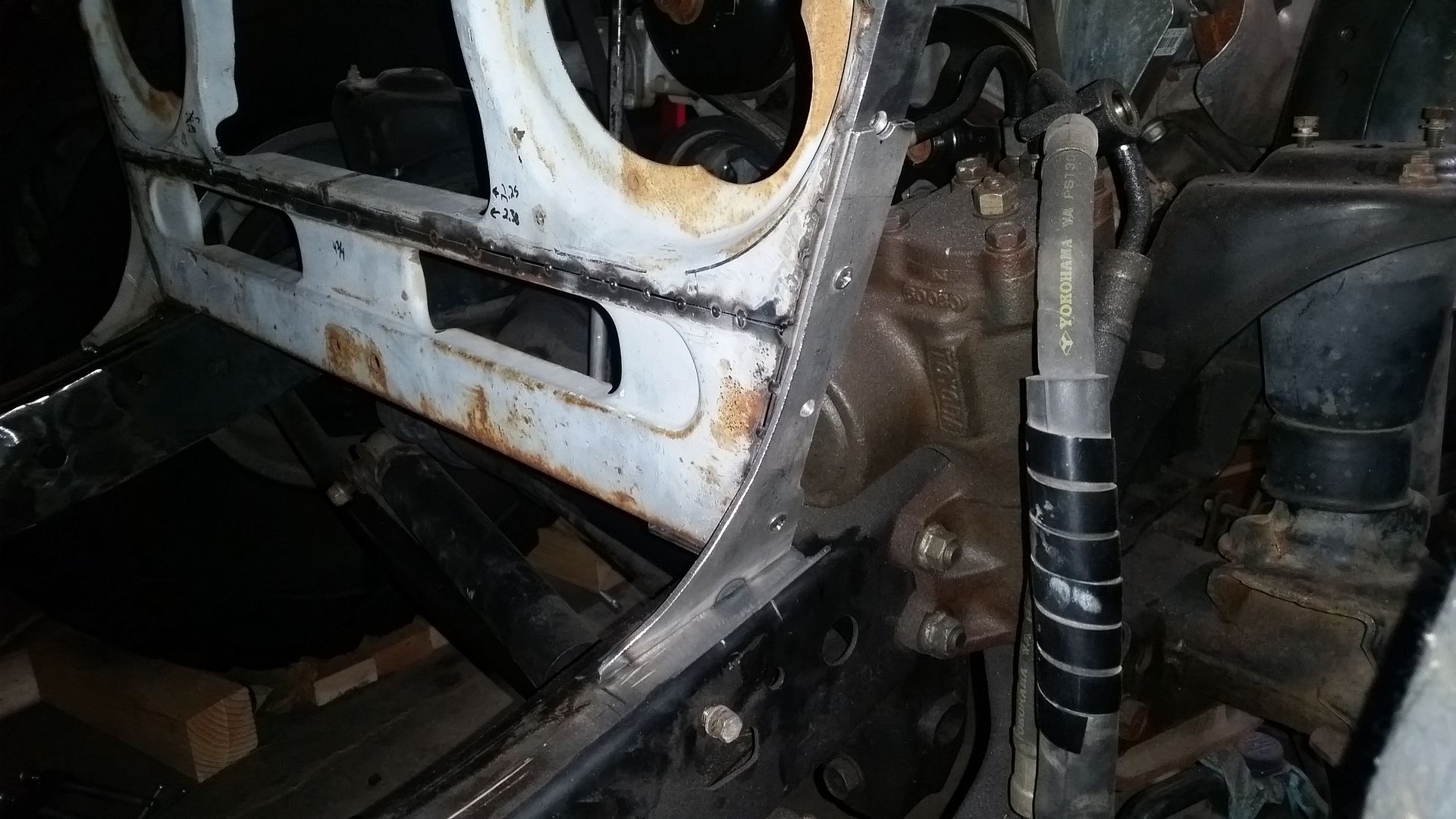

Generally, I want to eliminate the 'corners' below the headlights by moving them in about 4.38" and changing the shape to a trapezoid. This will leave the top and the bottom of the grill the same width as stock. The top matches the hood. The bottom matches the width of the 80-series frame pretty well.

The shell needed a bit of prep in order to provide room for the jig saw blade. I was actually able to keep all the brackets useable. I think the little ones hold the metal screen for the main grill opening. I have no idea what the one of the drivers upper corner does? Some kind of latch mount maybe? I don't think I will need to retain that one....

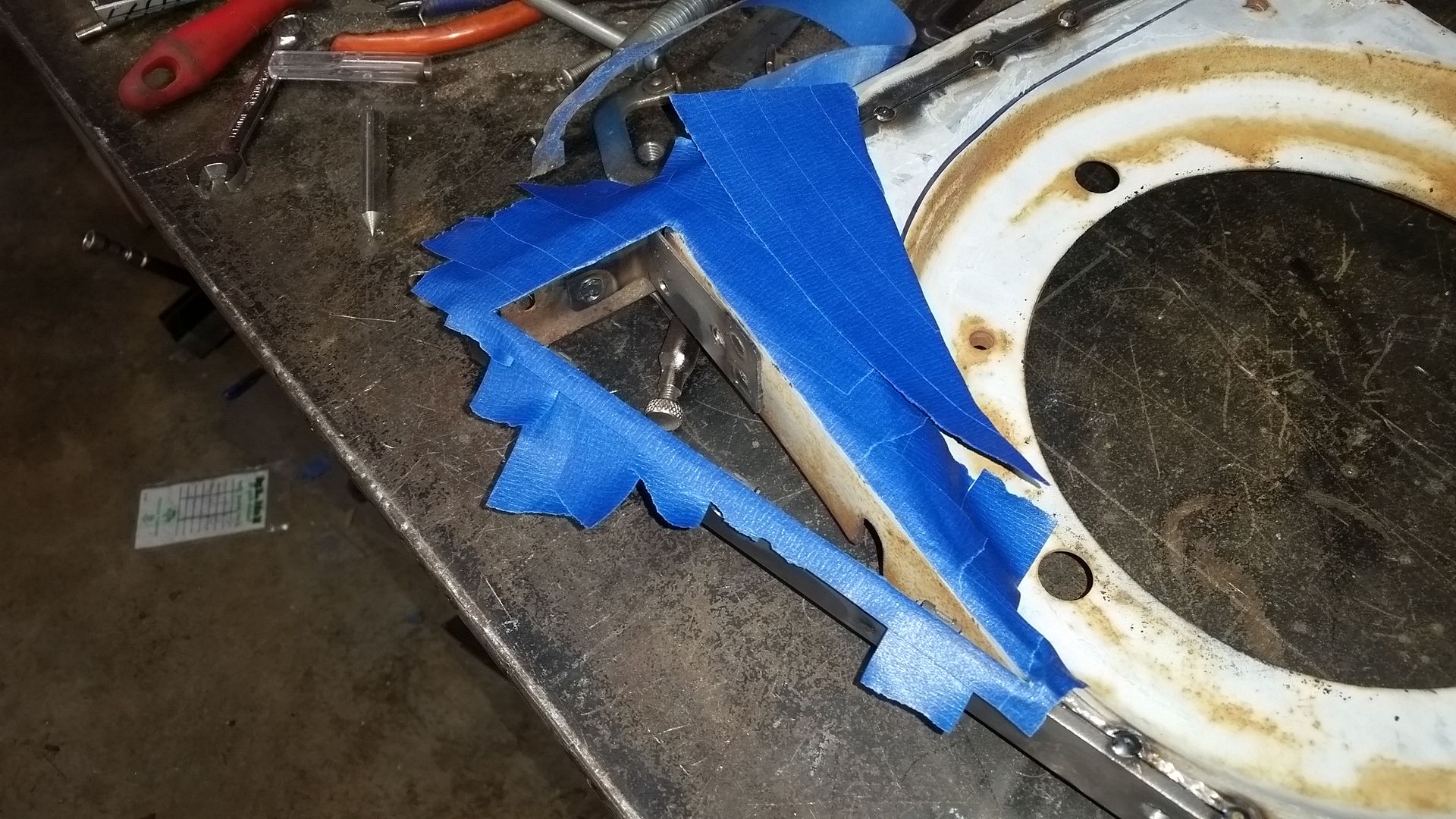

Cutting up into lots of pieces was fun.

This metal is pretty thin. I think it is 22 gauge or something. I need to look at picking up a small sheet for the areas I will need to add to make the new shape.

Once the edges where cut I cleaned them up with a file, dremel, flap wheel, a few swear words, and a little hammer work....

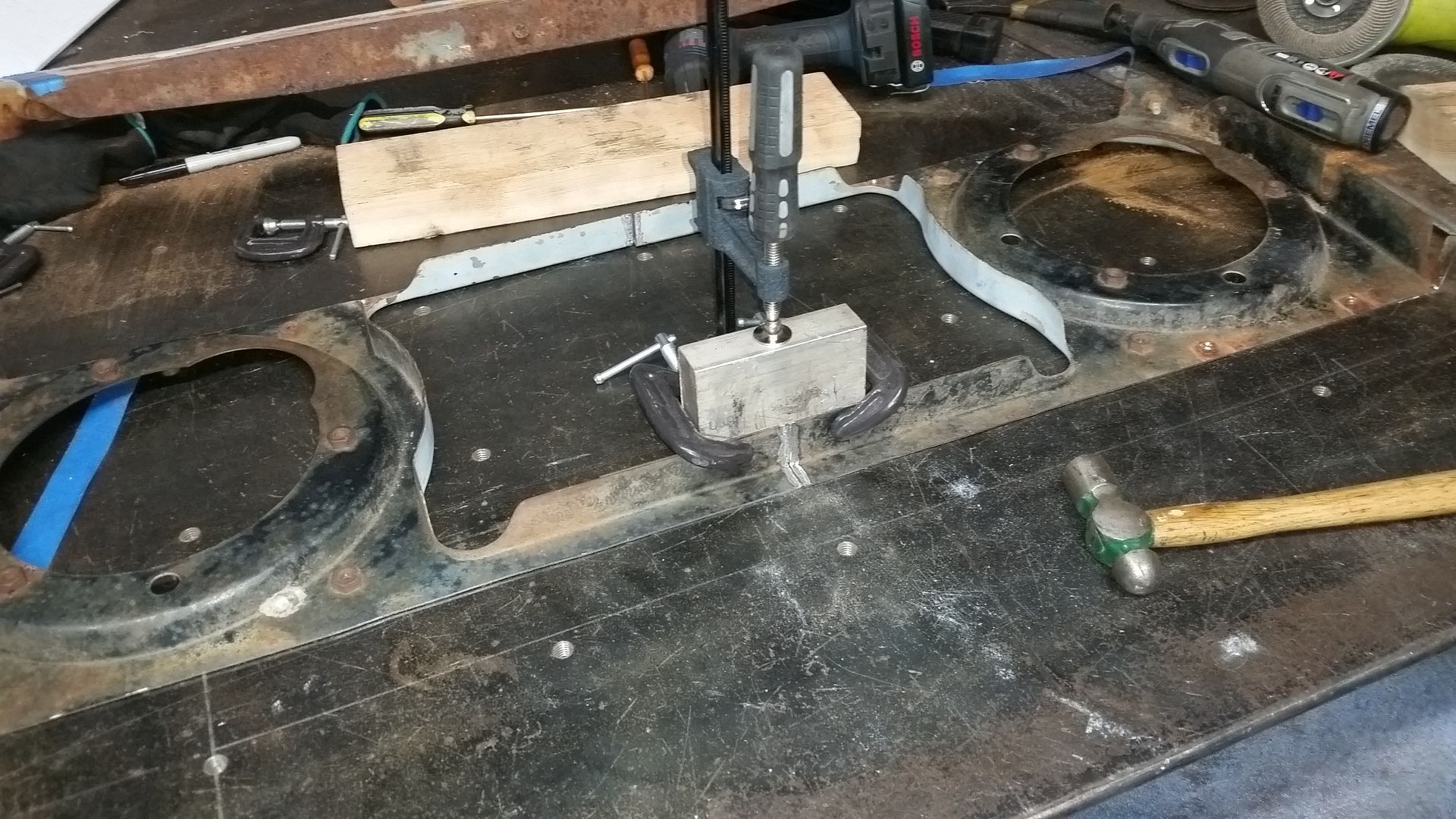

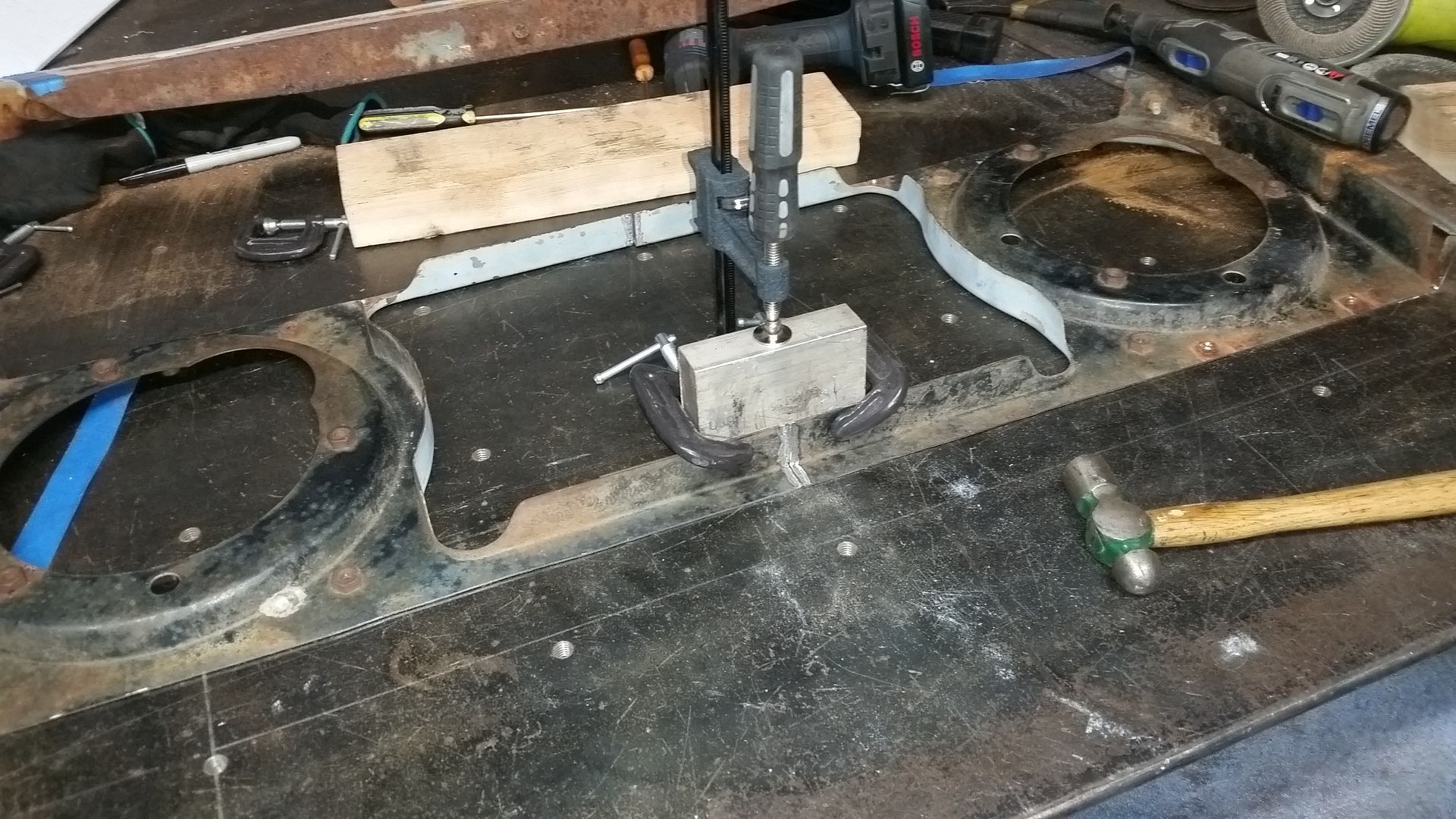

Here is the little jig I made for sticking the middle section back together after I removed the 4.38" from the middle.....

I need food. To be continued.

I am going to need to remake the shape of the grill.....why not....

Generally, I want to eliminate the 'corners' below the headlights by moving them in about 4.38" and changing the shape to a trapezoid. This will leave the top and the bottom of the grill the same width as stock. The top matches the hood. The bottom matches the width of the 80-series frame pretty well.

The shell needed a bit of prep in order to provide room for the jig saw blade. I was actually able to keep all the brackets useable. I think the little ones hold the metal screen for the main grill opening. I have no idea what the one of the drivers upper corner does? Some kind of latch mount maybe? I don't think I will need to retain that one....

Cutting up into lots of pieces was fun.

This metal is pretty thin. I think it is 22 gauge or something. I need to look at picking up a small sheet for the areas I will need to add to make the new shape.

Once the edges where cut I cleaned them up with a file, dremel, flap wheel, a few swear words, and a little hammer work....

Here is the little jig I made for sticking the middle section back together after I removed the 4.38" from the middle.....

I need food. To be continued.