You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blender, My LX450/FZJ80 + FJ45esk + GM + Land Rover crazy concoction

- Thread starter Metcalf

- Start date

Metcalf

Expedition Leader

Sheared off, But looks like the dowelpins still intact ?

Yup, and one stud still intact. My engineering opinion is that the studs and dowels don't provide enough clamping force to keep the flange from sliding on the mating surfaces. Over time ( in this case about 3 years ) this causes the studs to crack where the threads stop going into the drive flange. This causes cracking which eventually causes this failure. The studs where checked before the trip and have stayed tight pretty well honestly. I think the tire might have got bound up and generated enough movement to finally shear them off. The dowels are a little bit of a loose fit in the drive flange now also. These are 4340 RCV drive flanges with their 300m axle package and Trail Gear 'Super Metal' studs. Honestly, for 3 years of hard trail use, I can't really complain.

This does bring into question possible upgrades. My quick fix is slightly better quality ARP studs from Front Range Off Road, but they are still 8mm studs, but I think they will have the same long term problem. I think the final solution to make me happy long term is going to be more involved.

Metcalf

Expedition Leader

Ok. Makes sense then.

Aside from machining serrated matched surfaces. Reaming dowels tight and better fasteners is about all you can do...

Good luck with it.

Tons of other things that could be done.....stay tuned.

Metcalf

Expedition Leader

Some repairs on the #LX45 to keep it driving while I work on some more improvements.

-Power Steering pump was replaced again. This was another Napa/BBB 'new' pump, but this time I decided not to internally hot rod it, but I did keep the smaller pulley. I also flushed the heck out of the system with Swepco 729 and then bled the system extensively with Swepco 715. The bleeding program was at least 20+ full lock to lock cycles of the steering with the tires off the ground and the engine OFF. Then another 10+ with the engine idling and the tires still off the ground. I then took it easy on the pump slowly increasing driving RPM over a few days to help work out any final bubble. This seems to have worked as the new pump is completely quiet. It could have been the internal pump mods for more pressure that caused some of the issues, but I honestly think that you have to be MUCH more careful to get air out of the system before start-up. One big bubble of air getting to the pump at the wrong time can cause damage and that is what I think causes the noise.

-Tie-rod replaced with another 1.25 x 1/4" wall DOM steel unit. This worked for 3+ years, and the really good news is that the steering arms have stayed tight through the last year, and even through bending the old tie rod. I am looking at making a 1.38 or 1.5" diameter 7075-T6 aluminum unit along with the drag link ( and a drag link upgrade to 23mm joints to help with the hydro-assist ).

-Drive studs repaired and replaced. I feel like I should buy a lottery ticket after successfully drilling out all the studs. The last remaining stud also broke when removing it. Both dowel pins where still intact, but a little bit looser than they should be. All 6 studs failed at the threaded junction into the bearing hub....which is right at the mating surface of the flange. I think that is a pretty poor design in general and have a long list of details to improve things even with just the factory 8mm type studs.

-Power Steering pump was replaced again. This was another Napa/BBB 'new' pump, but this time I decided not to internally hot rod it, but I did keep the smaller pulley. I also flushed the heck out of the system with Swepco 729 and then bled the system extensively with Swepco 715. The bleeding program was at least 20+ full lock to lock cycles of the steering with the tires off the ground and the engine OFF. Then another 10+ with the engine idling and the tires still off the ground. I then took it easy on the pump slowly increasing driving RPM over a few days to help work out any final bubble. This seems to have worked as the new pump is completely quiet. It could have been the internal pump mods for more pressure that caused some of the issues, but I honestly think that you have to be MUCH more careful to get air out of the system before start-up. One big bubble of air getting to the pump at the wrong time can cause damage and that is what I think causes the noise.

-Tie-rod replaced with another 1.25 x 1/4" wall DOM steel unit. This worked for 3+ years, and the really good news is that the steering arms have stayed tight through the last year, and even through bending the old tie rod. I am looking at making a 1.38 or 1.5" diameter 7075-T6 aluminum unit along with the drag link ( and a drag link upgrade to 23mm joints to help with the hydro-assist ).

-Drive studs repaired and replaced. I feel like I should buy a lottery ticket after successfully drilling out all the studs. The last remaining stud also broke when removing it. Both dowel pins where still intact, but a little bit looser than they should be. All 6 studs failed at the threaded junction into the bearing hub....which is right at the mating surface of the flange. I think that is a pretty poor design in general and have a long list of details to improve things even with just the factory 8mm type studs.

8sixFabrication

Active member

I know I am pretty late to the party here, but I wanted to chime in and leave a (long winded) response.

Thanks for taking the time to write this all up and share your project. I really miss the days before FB killed a lot of activity on forums. I have sort of binge-read your thread over the past week or 2 when time allowed and its been great! I find the way you approach things and your train of thought very relatable. I am a fabricator and machinist by trade, and over the last year or 2, have gotten a little stale with my projects. Reading this thread all the way through has genuinely re-kindled the fire some for me and I am looking forward to getting back onto my Tacoma when my schedule allows.

I was motivated by your thread, to sign up on this forum and share my build thread that I started on TacomaWorld (lots of copying and pasting). I like the engagement with the members here so I am looking forward to seeing folks ideas and suggestions. Something you have mentioned in several posts was getting a little bit done daily. Back when I did a motor conversion on my 85 Toyota pickup, I tackled that similarly. I figured even 20 minutes staring at it to do a little problem solving, or 30 minutes pecking away at it added up in the long run. I tend to over think things and over build. This generally opens the door to some teasing from friends who don't see the value in the details, but I really go for a "factory like" installation.

After recently finishing the build out on my wifes 80 series, and getting a front 80 series axle hung under my Tacoma, I have fallen in love with that platform. Reading this thread has only amplified that. Now I am too, daydreaming about my next build. Possibly on an 80 series chassis, but with a mini-truck body... who knows. For now, I will plug away on my Tacoma, and hopefully be cool enough to be considered for UA after its done.

I happen to spend a fair amount of time in Colorado, so perhaps someday our paths will cross and we can geek out for a few.

Thanks for the inspiration. Now I need to dig up your other build threads and spend countless hours draining my laptops battery on those too!

--Long winded response over--

Thanks for taking the time to write this all up and share your project. I really miss the days before FB killed a lot of activity on forums. I have sort of binge-read your thread over the past week or 2 when time allowed and its been great! I find the way you approach things and your train of thought very relatable. I am a fabricator and machinist by trade, and over the last year or 2, have gotten a little stale with my projects. Reading this thread all the way through has genuinely re-kindled the fire some for me and I am looking forward to getting back onto my Tacoma when my schedule allows.

I was motivated by your thread, to sign up on this forum and share my build thread that I started on TacomaWorld (lots of copying and pasting). I like the engagement with the members here so I am looking forward to seeing folks ideas and suggestions. Something you have mentioned in several posts was getting a little bit done daily. Back when I did a motor conversion on my 85 Toyota pickup, I tackled that similarly. I figured even 20 minutes staring at it to do a little problem solving, or 30 minutes pecking away at it added up in the long run. I tend to over think things and over build. This generally opens the door to some teasing from friends who don't see the value in the details, but I really go for a "factory like" installation.

After recently finishing the build out on my wifes 80 series, and getting a front 80 series axle hung under my Tacoma, I have fallen in love with that platform. Reading this thread has only amplified that. Now I am too, daydreaming about my next build. Possibly on an 80 series chassis, but with a mini-truck body... who knows. For now, I will plug away on my Tacoma, and hopefully be cool enough to be considered for UA after its done.

I happen to spend a fair amount of time in Colorado, so perhaps someday our paths will cross and we can geek out for a few.

Thanks for the inspiration. Now I need to dig up your other build threads and spend countless hours draining my laptops battery on those too!

--Long winded response over--

Metcalf

Expedition Leader

I know I am pretty late to the party here, but I wanted to chime in and leave a (long winded) response.

--Long winded response over--

Thank you. And Thank you for taking the time to interact with the build thread! I really miss searchable forum tech and builds also.

VanIsle_Greg

I think I need a bigger truck!

Thanks for taking the time to write this all up and share your project. I really miss the days before FB killed a lot of activity on forums.

100% this. I come back here often, and over the past few years the activity has died off significantly. Having said that, there are lots of bright spots on here with lots of interesting builds and projects and adventures to follow... so still worth it.

This is one of them BTW. heh

Metcalf

Expedition Leader

Mini-Mod ( experimental ) on the #LX45 front axle....

I decided to try something different on the 80-series front axle after shearing off the alloy studs.

I didn't want to drill everything out larger......just yet....

This is a grade 12.9 ( Minimum tensile of 176,000psi ) 12-pt flange head 8mm-1.25 fastener with a partially threaded stem ( in all 6 factory locations). I bottom tapped all the factory holes to clean everything up and have as long a fastener as possible (within 1-2mm of the bottom ). The partially threaded stem extends below the shear plane between the flange and the bearing hub. I retained the factory cone washers and added a Nord-lock style locking washer system.

For extra insurance, I designed and cut these little laser cut tabs that additionally 'lock' the bolt heads to each other. I was able to shave the head on some additional 8mm bolts in the 'scallop' locations on the 80-series hub to act as pin retainers for the locking tabs. These feed through from the back side of the flange and use a locking nut for vibration. These don't transfer any load, they just hold the stainless locking tabs in place.

Stage two will be drilling and tapping the two factory dowel holes for two additional fasteners. ( 33% increase in clamping force and the same or better shear capacity ). My gut feeling is that the 80-series ( and most toyota ) locking hubs or drive flanges are suffering from a lack of clamping force. This allows the assembly to rock which typically creates long term cracking issues at the root of the 1st thread of the factory ( and aftermarket alloy ) studs.

We will see how this hold up over the next few seasons.

I should also do something on the rear axle, but it has been better with the additional dowel pin locations available. Even on the rear, I think extra clamping would be good vs just extra shear capacity.

I decided to try something different on the 80-series front axle after shearing off the alloy studs.

I didn't want to drill everything out larger......just yet....

This is a grade 12.9 ( Minimum tensile of 176,000psi ) 12-pt flange head 8mm-1.25 fastener with a partially threaded stem ( in all 6 factory locations). I bottom tapped all the factory holes to clean everything up and have as long a fastener as possible (within 1-2mm of the bottom ). The partially threaded stem extends below the shear plane between the flange and the bearing hub. I retained the factory cone washers and added a Nord-lock style locking washer system.

For extra insurance, I designed and cut these little laser cut tabs that additionally 'lock' the bolt heads to each other. I was able to shave the head on some additional 8mm bolts in the 'scallop' locations on the 80-series hub to act as pin retainers for the locking tabs. These feed through from the back side of the flange and use a locking nut for vibration. These don't transfer any load, they just hold the stainless locking tabs in place.

Stage two will be drilling and tapping the two factory dowel holes for two additional fasteners. ( 33% increase in clamping force and the same or better shear capacity ). My gut feeling is that the 80-series ( and most toyota ) locking hubs or drive flanges are suffering from a lack of clamping force. This allows the assembly to rock which typically creates long term cracking issues at the root of the 1st thread of the factory ( and aftermarket alloy ) studs.

We will see how this hold up over the next few seasons.

I should also do something on the rear axle, but it has been better with the additional dowel pin locations available. Even on the rear, I think extra clamping would be good vs just extra shear capacity.

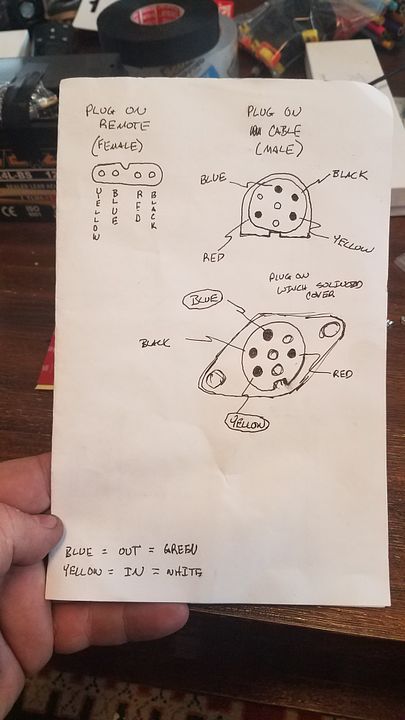

Thank you VERY MUCH for this extensive guide to installing the Albright and the Evo winch controller. I wanted to upgrade to a wireless controller for my Warn M10k winch, but wasn't sold on the Harbor Freight wireless unit that seems to be popular. This fits the bill perfectly for me. I don't need the Albright upgrade but if I ever do, I'll know where to find the info.

Metcalf

Expedition Leader

Mini-mod....

The #LX45 got one of my new HOSS fairleads installed.

This is my own design with some new features that help protect the synthetic line. You can read more about that here.

expeditionportal.com

expeditionportal.com

and here....

The #LX45 got one of my new HOSS fairleads installed.

This is my own design with some new features that help protect the synthetic line. You can read more about that here.

HOSS Fairlead

I thought I would share a new hawse design I have been working on for the last few years. This new hawse fairlead adds some very important features to the well established theory of using a smooth light aluminum hawse to guide synthetic lines on modern winches. Constructed from CNC...

expeditionportal.com

expeditionportal.com

and here....

Winch 'HOSS' Hawse Fairlead

Note: Current colors are in the latest pictures. The light straw/titanium color has been discontinued for the foreseeable future. My hard coating supplier is no longer able to provide it. I will work on bringing it back with another supplier at some point in the future. The latest batch now in...

brennans-garage.com

toddz69

Explorer

I got to my hotel late last Friday night and when I pulled in, I spotted a familiar rig (and tow rig) across the parking lot. Checked it out a bit more in the morning - I imagine I could spend quite a bit of time going over this thing.

Todd Z.

Todd Z.

Attachments

Metcalf

Expedition Leader

I got to my hotel late last Friday night and when I pulled in, I spotted a familiar rig (and tow rig) across the parking lot. Checked it out a bit more in the morning - I imagine I could spend quite a bit of time going over this thing.

Todd Z.

Thanks for following along! I hope you enjoyed checking out the #LX45 in person, I had just gotten off my #DoubleDusy trip ( two trips through the Dusy-Ershim trail in California because of the Courtright Dam Clousure ). It was a Dusy!

Similar threads

- Replies

- 6

- Views

- 955

- Replies

- 8

- Views

- 915

- Replies

- 12

- Views

- 4K

- Replies

- 2

- Views

- 3K