Stoffregen Motorsports

Explorer

That air dam is definitely a sure sign that you're headed down the OCD path. But I like it. I would never have thought of that.

That air dam is definitely a sure sign that you're headed down the OCD path. But I like it. I would never have thought of that.

Where did you find those extended weld nuts?

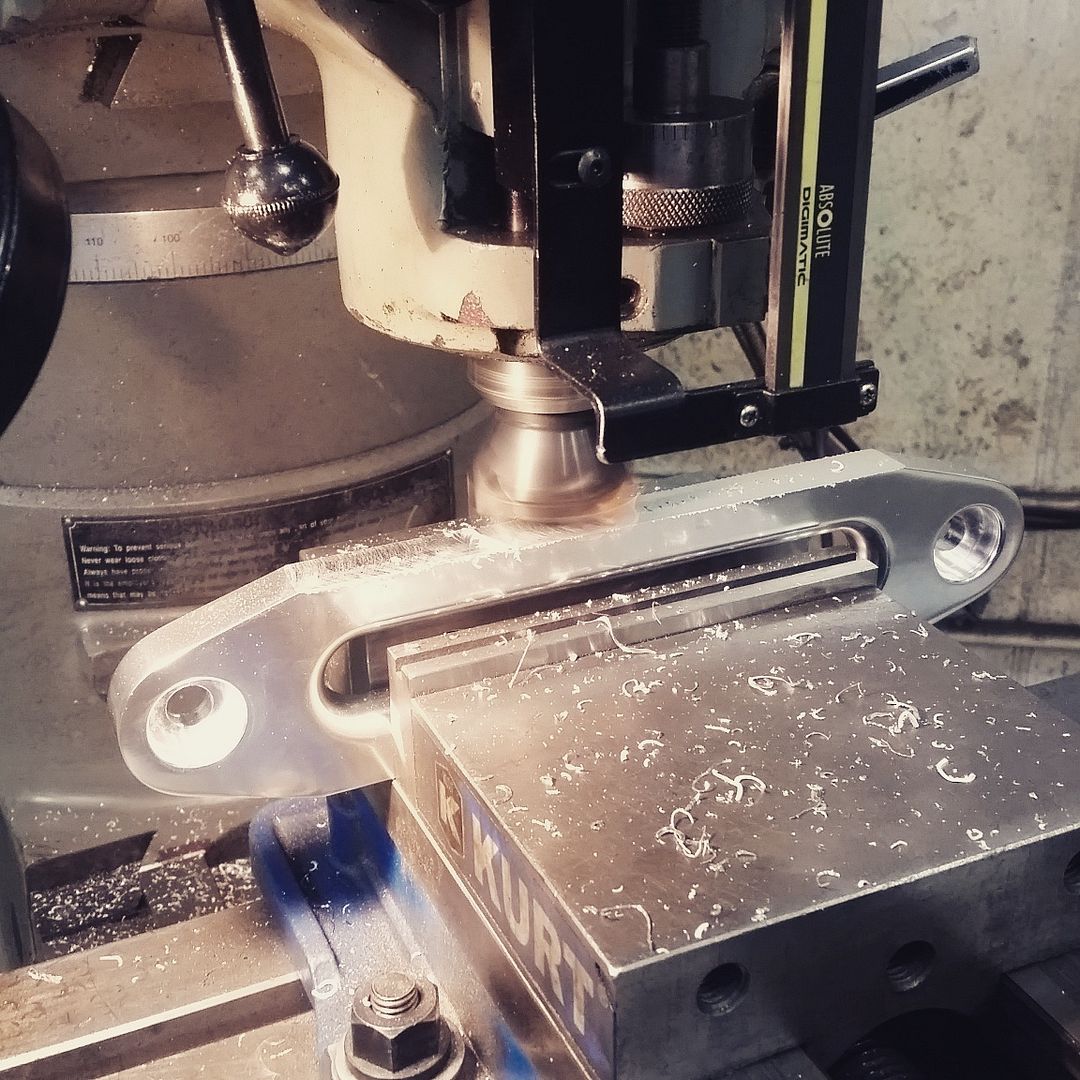

A lot of guys wouldn't see that. Your attention to detail is great, as always.

On the topic of headlights, while I get the desire to have great light output, those JW Speaker type headlights make me want to puke. They are sooooooo ugly, especially in old iron. (Don't even get me started on those stupid squinty eye headlight visor things people seem to be sticking on their JKs!). Again, I get it, having just gone through the "stock headlights suck" issue with my 100 and my 2014 Dodge. Why the OEM headlights have to be so terrible on a 2014 truck costing north of $50,000 is a mystery to me! I did hear from the Hella rep that there are new laws coming regarding minimum headlight performance in new vehicles.

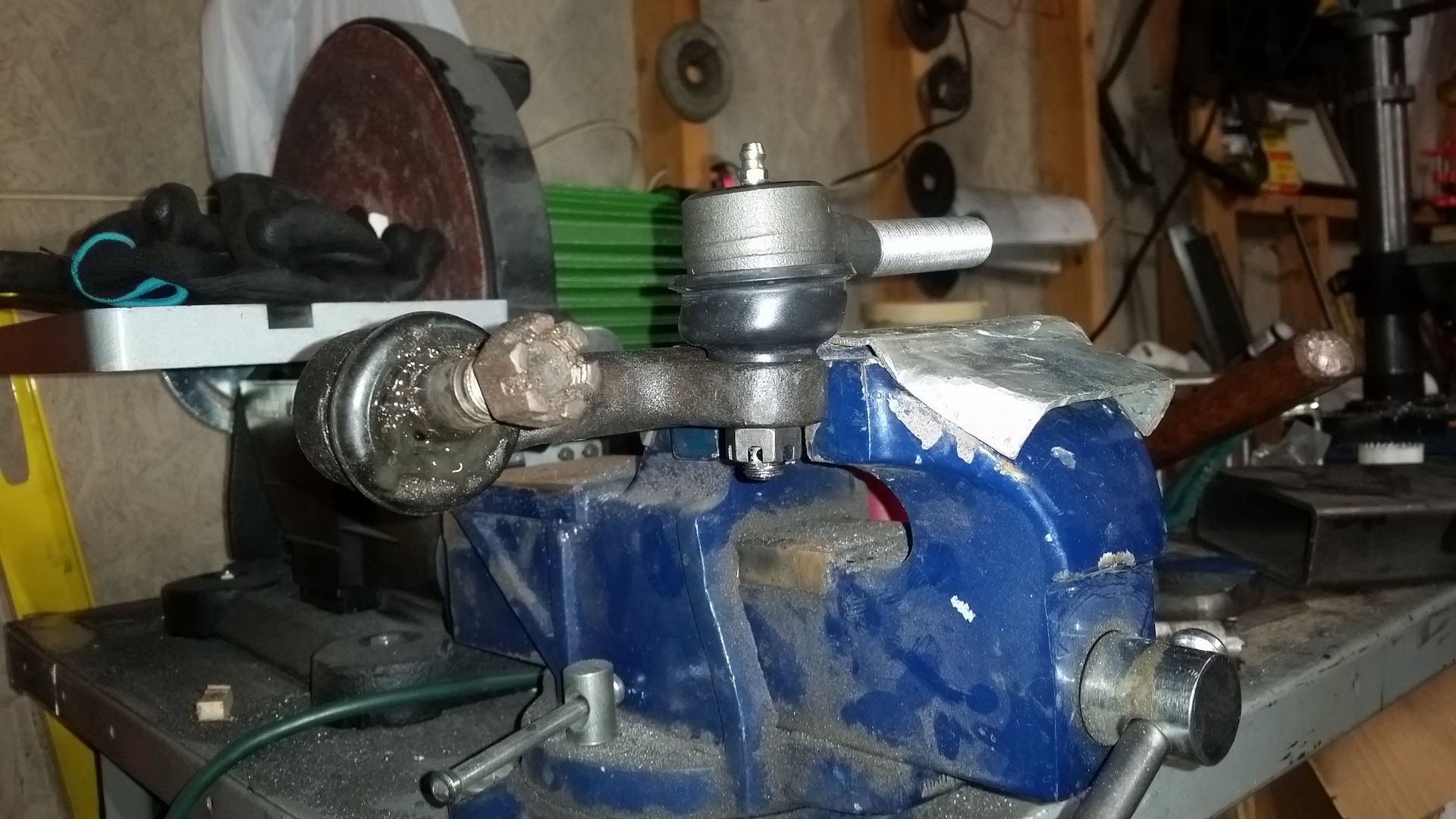

Using a TRE on a ram assist is a great idea. If it's a quality joint, it should last a very long time.

What wheels are you using? Size and offset/back space?

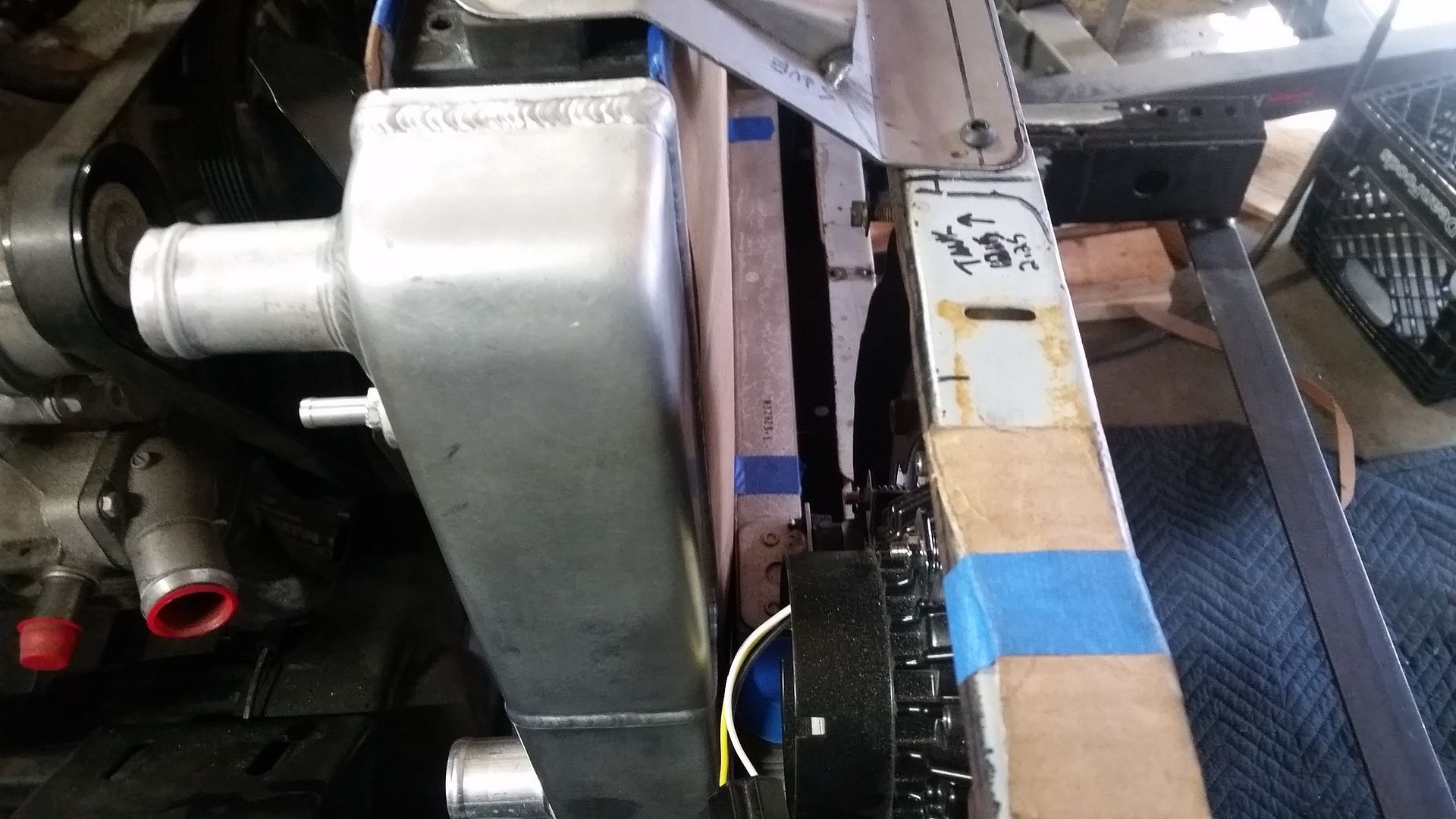

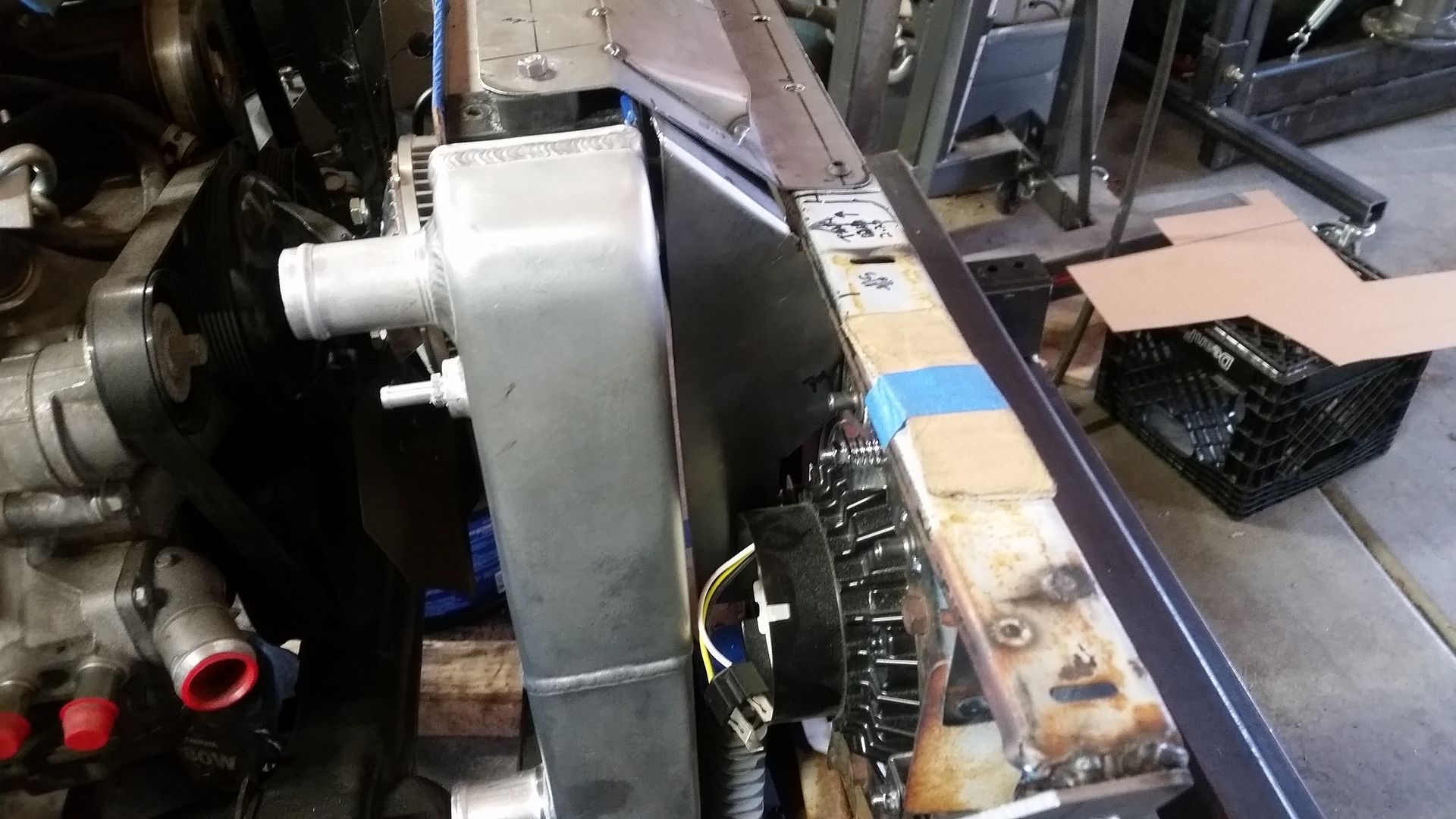

I was wondering how you achieved that tire clearance with those monster tires.

My friend Trevor Huiskens runs full hydro steering with OEM TRE's on his personal rig. I think he built it that way as a kind of in-your-face to the hardcore crowd, but it actually works.