You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

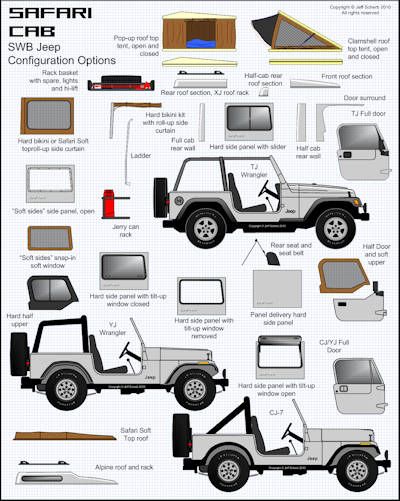

Bolt-together fiberglass Jeep-tub trailer kit

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

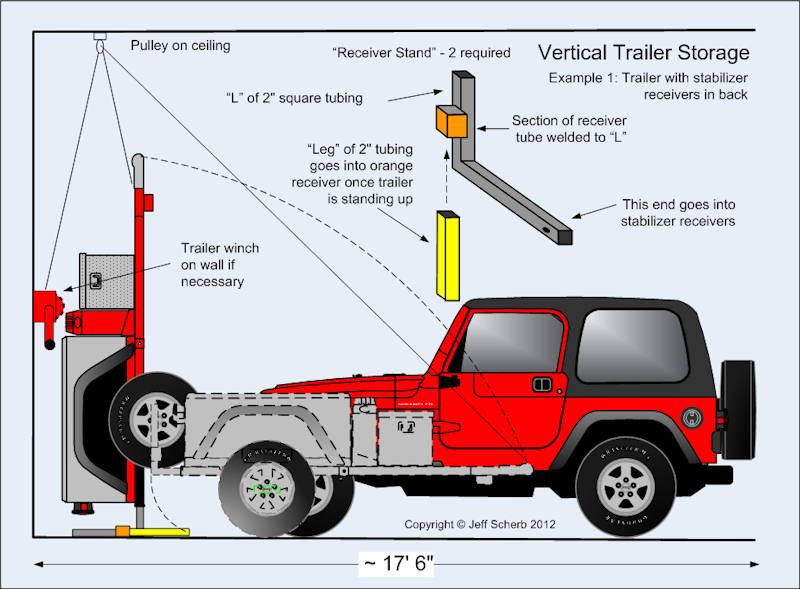

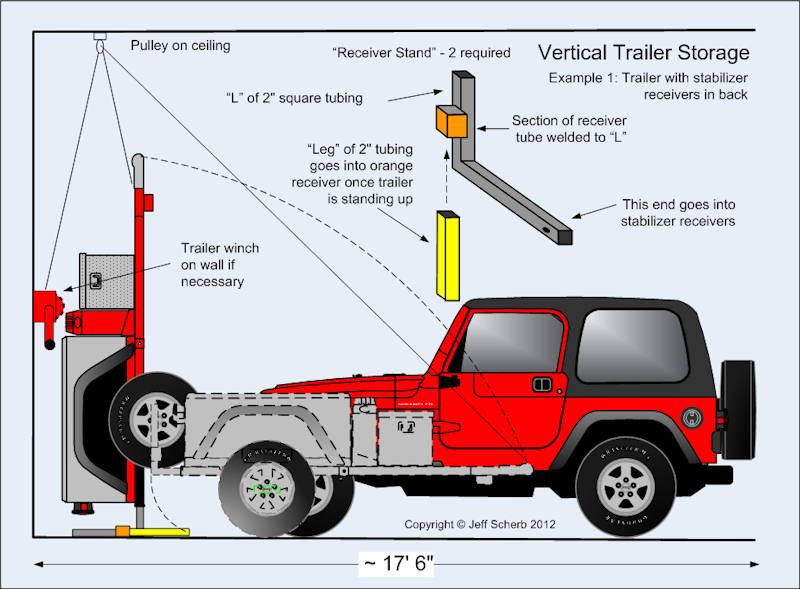

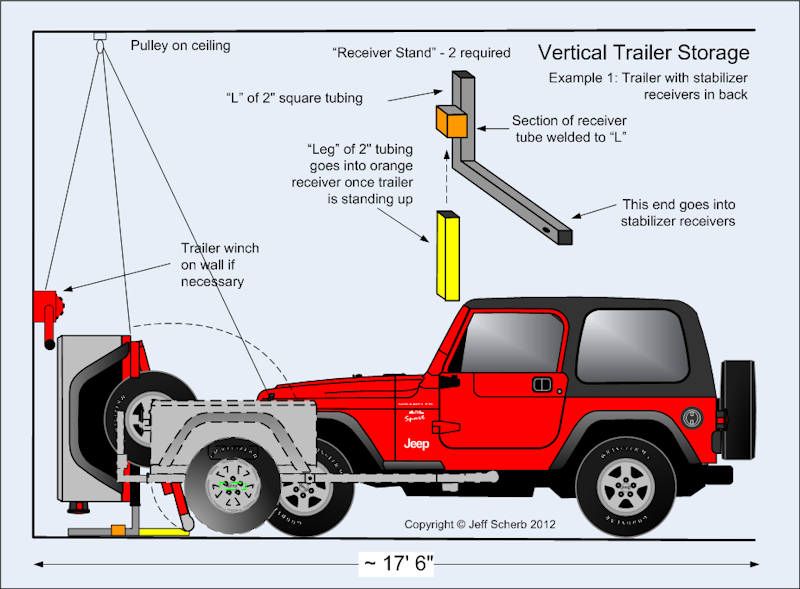

How to store a trailer when you don't have enough space in the garage...

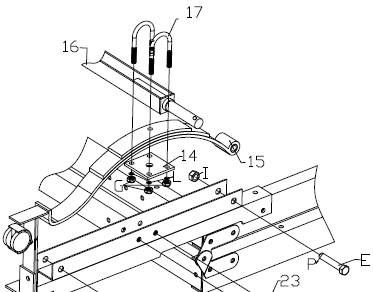

If you've got two receivers like the ones I installed for the stabilizer jacks on my black trailer:

... then some simple "L" stands of 2" square tubing form a basis for a simple "tip up" stand.

The L-stands in the drawing above each have a short piece of receiver welded to them for a front-facing stabilizing leg to slip into.

Depending of the weight of your trailer, it may take two people to tip it up, or you might want to attach an inexpensive boat trailer winch ($20 or so at HF) to the ceiling to pull the tongue up.

If you've only got a single centered receiver on the back of the trailer, you'd need a slightly more complicated stand, but the same principles apply.

If you've got two receivers like the ones I installed for the stabilizer jacks on my black trailer:

... then some simple "L" stands of 2" square tubing form a basis for a simple "tip up" stand.

The L-stands in the drawing above each have a short piece of receiver welded to them for a front-facing stabilizing leg to slip into.

Depending of the weight of your trailer, it may take two people to tip it up, or you might want to attach an inexpensive boat trailer winch ($20 or so at HF) to the ceiling to pull the tongue up.

If you've only got a single centered receiver on the back of the trailer, you'd need a slightly more complicated stand, but the same principles apply.

jscherb

Expedition Leader

Here's a quick storage idea - most auto parts stores, WalMart, etc., sell storage nets that are designed to go behind the back seat of an SUV. I ran across one yesterday in a surplus store for a price I couldn't resist, so I bought it because thought it might work nicely in the trailer:

The net came with mounting hardware, but it isn't necessary because the bolt flanges between the front panel and side panels are natural places for mounting. For this photo, I just used some small $1-each HF c-clamps to mount the net, but the flanges could be drilled for additional bolts to make it more permanent.

The c-clamps are actually a nice way to go because the net could be quickly installed/removed.

The net came with mounting hardware, but it isn't necessary because the bolt flanges between the front panel and side panels are natural places for mounting. For this photo, I just used some small $1-each HF c-clamps to mount the net, but the flanges could be drilled for additional bolts to make it more permanent.

The c-clamps are actually a nice way to go because the net could be quickly installed/removed.

What is the total length of your trailer? Your drawing above doesn't show the height when standing the trailer up vertical. I have a one car garage but I do have the depth to stand a trailer up, just not sure of the total length of the trailer. This might be a very practical investment since I traded my truck in on a Jeep last month!

jscherb

Expedition Leader

What is the total length of your trailer? Your drawing above doesn't show the height when standing the trailer up vertical. I have a one car garage but I do have the depth to stand a trailer up, just not sure of the total length of the trailer. This might be a very practical investment since I traded my truck in on a Jeep last month!

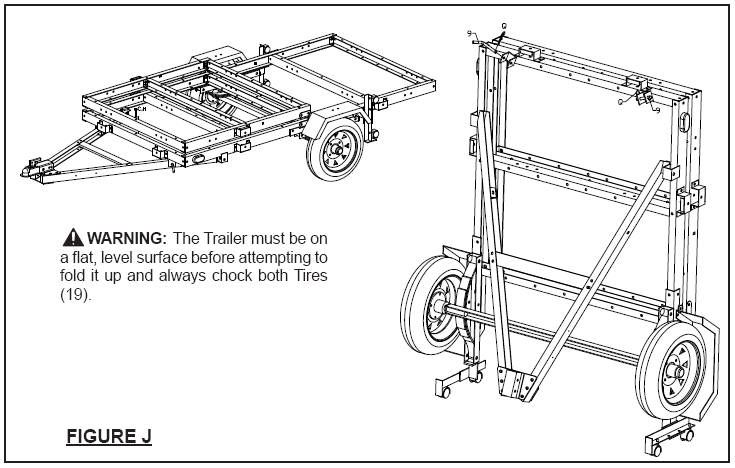

The black trailer is just about 8' long from the back of the tub to the end of the receiver on the tongue. Since this is a kit designed to be built on a frame of your choice, if you wanted a shorter overall length you could build the frame with a shorter tongue, or build it with a removable tongue by using a receiver right at the front of the frame. Doing that, the trailer would be just over 4' long and could stand anywhere.

Some of the Harbor Freight frames have a folding tongue, so that would be a way to reduce the standing height as well.

With a folding tongue, it could be like this:

Last edited:

jscherb

Expedition Leader

No clip art, I do all of my drawings from scratch using Microsoft Visio.What software do you use to make your illustrations? And are you creating the Jeep views, or are they clip art?

jscherb

Expedition Leader

I won't claim that every line is precisely to scale, but generally the drawings are pretty accurately scaled - they need to be accurate so that I can accurately visualize designs I'm working on.I was curious about your drawings too. They sure look like they are correct to scale blueprint drawings. Are they really to scale or are you just that good at visualizing how things look?

One of the nice things about Visio is that you can create collections of drawing parts (Visio calls them stencils), and then drag-and-drop parts from the stencils to create complete drawings. I've got tons of Jeep stencils from all of the drawings I've made, so it's very quick and easy to create new Jeep variation drawings...

Last edited:

M35A2

Tinkerer

No clip art, I do all of my drawings from scratch using Microsoft Visio.

I'm very impressed. That is not the easiest tool to create shapes with accurate (to real life) compund curves.

jscherb

Expedition Leader

I have the split trailer from harbor freight, but the wheels is 4 lugs. What did you do to adapt the jeep wheels? CAn you show us? I really like your project and would like to try it myself. I never done this before. any recommendations would help. thank you.

David,

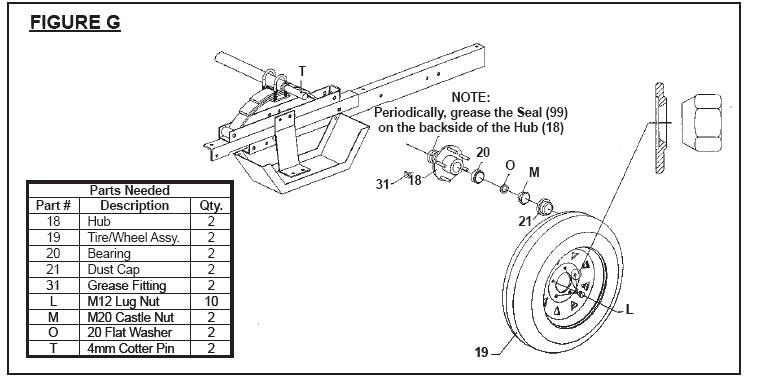

I used the HF 94564 1720-lb. capacity trailer, which comes with a 5-lug, 5-on-4.5 (same as the Jeep) bolt pattern on a 2000-lb. capacity axle. All of the other lighter capacity HF trailers, like yours, come with 4-lug hubs and a lighter-duty axle.

There are several ways to change your trailer to 5-lug hubs, but before I list them, a word of caution - the axles that come with the lighter-duty HF trailers are made from light-gauge sheet metal folded into a u-channel, see the HF drawing clip below. This axle is designed for loads under 1500-lbs. total and 12" tires. Putting Jeep-sized tires on that axle may cause forces that exceed the strength of the axle. Use good judgement in whatever you do with the light-duty HF axles.

So here are some ways to do it:

1. Wheel adapters. The only wheel adapters I've seen that go from 4-on-4 to 5-on-4.5 are designed for golf carts, so perhaps not heavy enough for road trailer usage. If anyone else has a source for heavier-duty adapters, I'd be interested in hearing about them. I can give you a link to the golf cart adapters, but I hesitate to post it because I don't know if they'd really be up to the task.

2. Replace the hubs. Unfortunately since the HF axles are metric, and pretty much all of the 2000-lb. 5-lug replacement trailer hubs you'll find in stores like Tractor Supply are designed for either 1" or 1 1/6" axles, you might have trouble finding hubs or bearings to fit. However, the 4-lug and 5-lug HF hubs all take the same bearings and axles, so you could order replacement 5-lug hubs from HF nd swap them on, you could even reuse your current bearings (although the bearings are not very expensive so maybe a false economy). Here's a clip from the 94564 trailer assembly manual, you could call the HF 800 number with the 94564 kit # and hub part # (18) and see how much replacements would cost. But you'd still have the cheesy sheet metal axle.

3. What I'd recommend is getting a new axle, and I'd recommend it for two reasons - first because you'd be replacing the cheesy sheet metal axle, and second, you could get the axle made a bit wider so you could actually fit Jeep-sized tires on the trailer without them rubbing the frame - take a look at your trailer and you'll see there isn't much clearance between the tiny 12" tires and the frame rails, you won't fit a wider Jeep tire on there.

A complete replacement axle with hubs can be had for as little as $102 (http://kmtparts.com/axles-spring-mounted/2000-lbs-axle.html) or $112 (http://kmtparts.com/axles-spring-mounted/3500-lbs-axle.html).

You didn't specifically say you wanted 5-lug hubs so you could run Jeep wheels and tires, but one more note - if you're thinking of running Jeep Wrangler factory alloy wheels, the center hole in those wheels is too small to fit over the entire trailer hub, so you'll need 1.25" 5-lug spacers to space the wheel out enough so the tiny center hole clears the hub.

You'd have to do specific measurements for the tires/wheels you planned to run, but if you ordered a new axle with the spring seats the same distance apart as the springs on your HF frame but the axle itself being 4" longer figuring 1.25" spacers would also be used, or perhaps 7" longer if you wanted to run Jeep steel wheels, you'd pick up enough length to clear the frame with Jeep-sized wheels and tires.

If you need any more info let me know.

David,

You didn't specifically say you wanted 5-lug hubs so you could run Jeep wheels and tires, but one more note - if you're thinking of running Jeep Wrangler factory alloy wheels, the center hole in those wheels is too small to fit over the entire trailer hub, so you'll need 1.25" 5-lug spacers to space the wheel out enough so the tiny center hole clears the hub.

.

Do you know if it's possible to get the center hole bored out on a factory Jeep alloy wheel(I know you can but...) Not sure if there is enough "meat" for the wheel to still retain it's strength.

jscherb

Expedition Leader

I wouldn't even want to hazard a guess on that one, but I'll offer this comment - one of the nice things about having the trailer be compatible with the Jeep wheels is that you can share a spare between the Jeep and the trailer. If you modify a pair of Jeep wheels to fit the trailer, rather than the other way around, you won't be able to share a spare unless you also modify the Jeep's spare.Do you know if it's possible to get the center hole bored out on a factory Jeep alloy wheel(I know you can but...) Not sure if there is enough "meat" for the wheel to still retain it's strength.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 6

- Views

- 2K

- Replies

- 2

- Views

- 1K