You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boomer the Quadravan 4x4 Camper

- Thread starter spencyg

- Start date

Arctic Travelller

Adventurer

Now thats very cool..........:victory:

guidolyons

Addicted to Gear Oil

SG,

Nice work as always. That antenna limit strap is way cooler than using an old tennis ball. The diff cover is Kustom (yeah custom with a K) SG awesomeness. That should scare the rocks into submission. If you manage to dent that one, get a diff cover from Ruff Stuff Specialties 3/8" thick, welded inside and out, and milled flat for a leak free fit. http://www.ruffstuffspecialties.com/catalog/diffcovers.html

Look forward to the trip report :sombrero:

Nice work as always. That antenna limit strap is way cooler than using an old tennis ball. The diff cover is Kustom (yeah custom with a K) SG awesomeness. That should scare the rocks into submission. If you manage to dent that one, get a diff cover from Ruff Stuff Specialties 3/8" thick, welded inside and out, and milled flat for a leak free fit. http://www.ruffstuffspecialties.com/catalog/diffcovers.html

Look forward to the trip report :sombrero:

rex blackfire

New member

Amazing rig, and an amazing thread! Shoot I'm still trying to figure out what ends, drag link, and bushings I need to get my front end proper in my 78! I could just dump it on the local alignment guru, but that turns a $300 job into a $700 job, and I'd rather do the work myself. Even with a worn out front end, and 9 other vehicles, this is the one I just cant quit driving!

Hey thanks! Sorting out the front end components for old Pathfinder conversion vans is challenging on a good day. Honestly, since Gordon shut down his pathfinder van site I don't even know where I'd start looking for various rubber bits.

As a follow up to the pre-trip work documented in the last few posts, the antenna damping/isolating device worked very very well. I put the rig through some pretty dense scrub on the trail and bonked the antennas countless times...only once or twice did they contact the camper top, and they never touched each other. The compliance in the bungee allowed the antennas to move around to avoid bending or breaking all while keeping everything within a non-contact area on the side of the rig. Very cool. The 5W handheld HAM radio (Baofeng GT-3) made as good a use of the external antenna but only afforded me a range of around 7 miles to other Hams in the group. Others had Yuasu knock-off 50W units and were doing no better with their external antennas, so I think I'm probably as good as possible. I won't change the HAM antenna position for the time being as I didn't experience any static between the heavily used CB and the HAM throughout the trip.

Didn't break out the traction boards at all which is fine by me.

I'm headed back into the woods this weekend for just an overnight for some deep woods fly fishing. Be looking for pics...hopefully of great adventures AND great fish!

SG

As a follow up to the pre-trip work documented in the last few posts, the antenna damping/isolating device worked very very well. I put the rig through some pretty dense scrub on the trail and bonked the antennas countless times...only once or twice did they contact the camper top, and they never touched each other. The compliance in the bungee allowed the antennas to move around to avoid bending or breaking all while keeping everything within a non-contact area on the side of the rig. Very cool. The 5W handheld HAM radio (Baofeng GT-3) made as good a use of the external antenna but only afforded me a range of around 7 miles to other Hams in the group. Others had Yuasu knock-off 50W units and were doing no better with their external antennas, so I think I'm probably as good as possible. I won't change the HAM antenna position for the time being as I didn't experience any static between the heavily used CB and the HAM throughout the trip.

Didn't break out the traction boards at all which is fine by me.

I'm headed back into the woods this weekend for just an overnight for some deep woods fly fishing. Be looking for pics...hopefully of great adventures AND great fish!

SG

justcuz

Explorer

I read your entire thread on this vehicle and also your comments on the other thread about fixing the front axle travel issues. The reason you do not have a Dana 44 HD with extra ribs in the housing is that you have a high pinion front axle. HD Dana 44 front axles were only low pinion with the large external hub 6 bolt flange. Basically it was for a higher GVW Camper Special, Snow Plow, etc that allowed the heavier axle tubes, bigger wheel bearings and u joints. In the old closed knuckle king pin front axles they actually had bigger balls and Dana 60 outers. 1976-1977.5 were the only low pinion, open knuckle, disc braked, big hub Dana 44 HD front axle.

You are actually better off with what you have because all the Dana 50 TTB center sections are actually Dana 44 parts.

I enjoy reading your posts and travel reports, so I thought I would contribute a little to your knowledge base.

You are actually better off with what you have because all the Dana 50 TTB center sections are actually Dana 44 parts.

I enjoy reading your posts and travel reports, so I thought I would contribute a little to your knowledge base.

BajaSportsmobile

Baja Ironman

You are actually better off with what you have because all the Dana 50 TTB center sections are actually Dana 44 parts.

They are not - they are Dana 50. Different carrier, different R&P...

I read your entire thread on this vehicle and also your comments on the other thread about fixing the front axle travel issues. The reason you do not have a Dana 44 HD with extra ribs in the housing is that you have a high pinion front axle. HD Dana 44 front axles were only low pinion with the large external hub 6 bolt flange. Basically it was for a higher GVW Camper Special, Snow Plow, etc that allowed the heavier axle tubes, bigger wheel bearings and u joints. In the old closed knuckle king pin front axles they actually had bigger balls and Dana 60 outers. 1976-1977.5 were the only low pinion, open knuckle, disc braked, big hub Dana 44 HD front axle.

You are actually better off with what you have because all the Dana 50 TTB center sections are actually Dana 44 parts.

I enjoy reading your posts and travel reports, so I thought I would contribute a little to your knowledge base.

Thanks for the info. I wasn't aware of the low pinion vs high pinion for the Dana 44 HD axle so this is helpful. Once in awhile I get a bee under my bonnet about upgrading both the front and rear axles, but the van does well with the running gear I've got and I've never seen any signs of overloading when I've swapped out bearings. Regardless, knowing what I've got and the history behind it is always good.

I have done a few things with the rig over the last couple weeks as a result of going on a couple small trips into the woods which highlighted some needs for improvement.

#1 was the decision to finally install my hood vents. I did this after some hot weather trail driving a couple weeks back. I never overheated either the engine or transmission, but everything was running hotter than I wanted. Adding the vents took only a couple hours and the difference has been noticeable. I think I could probably justify adding a second pair at some point, but for now these cut my trail riding temps down to normal levels and I think I'm also seeing some benefit at highway speeds.

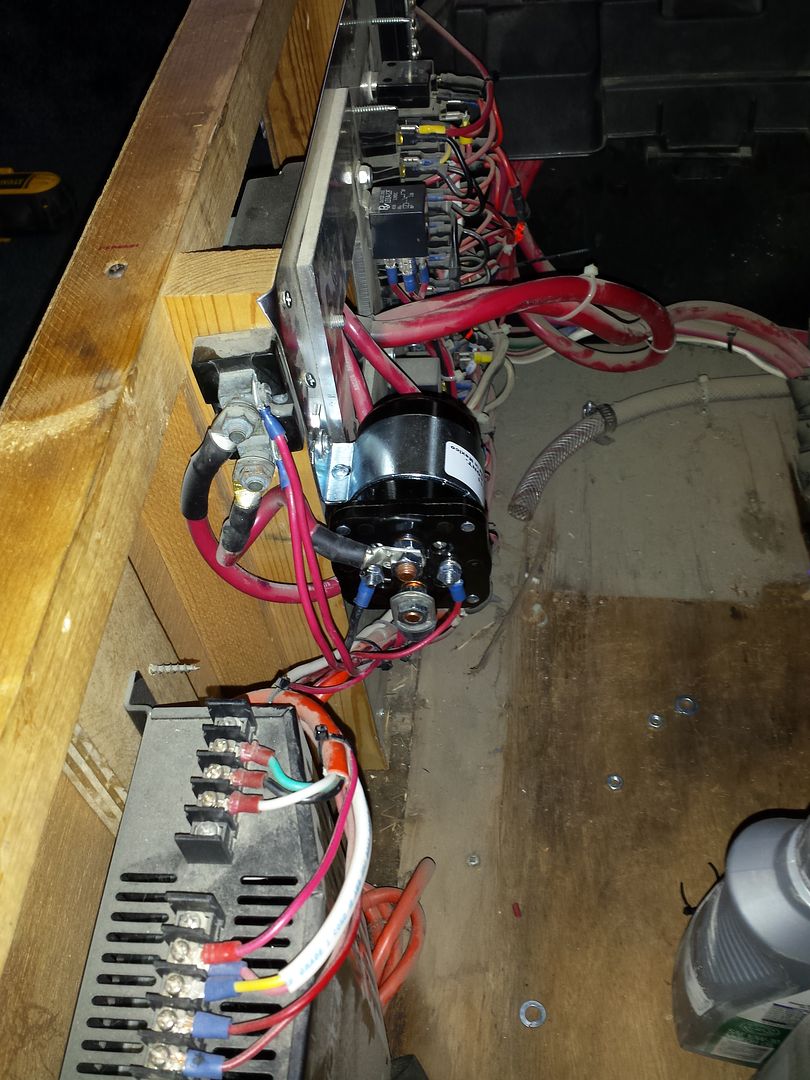

I've noticed my compressor solenoid and associated wiring getting a little too warm lately when airing up. I don't know whether the solenoid I had in there (generic 40A black box we are all familiar with) was on its way out or what, but it was too hot to touch last time I had the compressor running for maybe 20 minutes. While I was in there poking around I also noticed that my battery bank isolation solenoid was very hot as well. Instead of just ignoring it and hoping the fire extinguisher worked, I ponied up for a couple new solenoids and a wiring upgrade for the compressor.

The new isolation solenoid is a 200A continuous duty unit, and the compressor solenoid is a 80A continuous duty model. Once I started installing things, I opted to use an older Bosch 75A continuous solenoid for the compressor as it was a smaller package and was going to make for a cleaner install. I did pull the original 12 gauge wiring that ran the compressor and put in some very serious SJO 10/2. I now have no more heating issues with the solenoid and the wiring is comfortably oversized. Needless to say, everything was zip tied back and plenty of chafe protection was installed on the new compressor wiring where it passes thru the body and runs along the frame.

We just returned back from a short 4 day family adventure into the Maine woods (trip report will happen soon), and due to the slow trail riding conditions and far more "play" than travel, we killed the house batteries on the 4th morning. I wasn't able to utilize solar for more than maybe 6 hours all weekend and the stock 2G alternator doesn't put out its full 60A (!!!) until 2000RPM. It is clearly time for the 3G alternator upgrade and that will be happening in the next couple weeks. I also need to add more 12V fans to the roster as it was hot in the woods and a single fan just wasn't cutting it at night. Beyond that, all the systems are working well and Boomer is generally just kicking some serious butt.

SG

justcuz

Explorer

They are not - they are Dana 50. Different carrier, different R&P...

You are right, I stand corrected, there is a light duty 8 lug Dana 44 TTB that has the smaller hubs and 44 R&P.

guidolyons

Addicted to Gear Oil

Check marine/boating stores for hood louvers.

I got some nice stainless steel hood louvers /vents from Jamestown Distributors. They have different sizes and styles depending on how much room you have.

I got some nice stainless steel hood louvers /vents from Jamestown Distributors. They have different sizes and styles depending on how much room you have.

dazdconfsd

Observer

This is an awesome thread and has given me some more ideas on the Intervec Falcon 190 I recently acquired. One question though, I saw in the pictures and trip report that the front windows on the top had been patched with silicon, and then the silicon appears to have been removed for a different solution. Mind sharing what that was?

The silicone wasn't removed...its still there and doing its job. The big problem is that the rubber weather seal around each quarter window is totally shot and sun cracked. I have every intention of blanking in those 2 windows with fiberglass since light up there isn't necessary and the windows are a fragile spot...especially when bombing through overgrown trail systems. The gasket material is readily available from RV and Marine suppliers, but I want the clear sections gone anyway.

SG

SG

Bikersmurf

Expedition Leader

I'd look into a bigger alternator than a 3G... I like seeing 80 amps at Idle, 120 by 1200 rpm and 215 amps by about 1500 rpm.

I'm actually going to be doing the alternator upgrade in the next couple weeks. We did a small family woods adventure a couple weeks back and lopsided ratio of driving to playing (I don't see a distinction between the two but my daughters completely disagree) left me with dead batteries on the 4th morning. The current alternator is a 1G and charges no more than 20A at idle and only 50A at cruise. Terrible. It hadn't caught up with me in years because either we were camped for an extended period and I was leveraging solar, or we were on the move and continually charging. Where we camped a couple weeks ago there were too many trees each day for solar and we were idling on trails for no more than 3 hours a day.

Normally I'd agree with "bigger is better" when it comes to alternators, but one needs to respect the wiring in which you're dumping serious current into. The stock charging circuit is now nearing 30 years old and my isolation solenoid has a max rating of 200A continuous. To dump 200A thru the circuit for hours on end during a deep discharge would make me pretty uncomfortable. The stock 3G alternators from mid 90's Windstars/Taurus platforms do 100A at idle and have been proven to go upwards of 150A peak. I already have a new harness adapter for the 3G alternator and they can be easily found anywhere in case of replacement concerns on the road. If I was running an ambulance conversion the choice for a larger unit would be obvious. For Boomer, I'm going to tend toward the conservative on this one...

SG

Normally I'd agree with "bigger is better" when it comes to alternators, but one needs to respect the wiring in which you're dumping serious current into. The stock charging circuit is now nearing 30 years old and my isolation solenoid has a max rating of 200A continuous. To dump 200A thru the circuit for hours on end during a deep discharge would make me pretty uncomfortable. The stock 3G alternators from mid 90's Windstars/Taurus platforms do 100A at idle and have been proven to go upwards of 150A peak. I already have a new harness adapter for the 3G alternator and they can be easily found anywhere in case of replacement concerns on the road. If I was running an ambulance conversion the choice for a larger unit would be obvious. For Boomer, I'm going to tend toward the conservative on this one...

SG

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 5

- Views

- 2K

- Replies

- 12

- Views

- 3K